Composite insulator, manufacturing method thereof and composite sleeve

A composite insulator and manufacturing method technology, applied in insulators, insulators, support insulators, etc., can solve the problems of reduced service life of shed insulation tubes, interference of composite insulators, large inner diameter, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] As required, specific embodiments of the invention will be disclosed herein. However, it should be understood that the embodiments disclosed herein are merely typical examples of the invention, which can be embodied in various forms. Therefore, specific details disclosed herein are not to be considered limiting, but merely as a basis for the claims and as a representative basis for teaching one skilled in the art to variously employ the invention in any appropriate way in practice, This includes taking various features disclosed herein and combining features that may not be expressly disclosed herein.

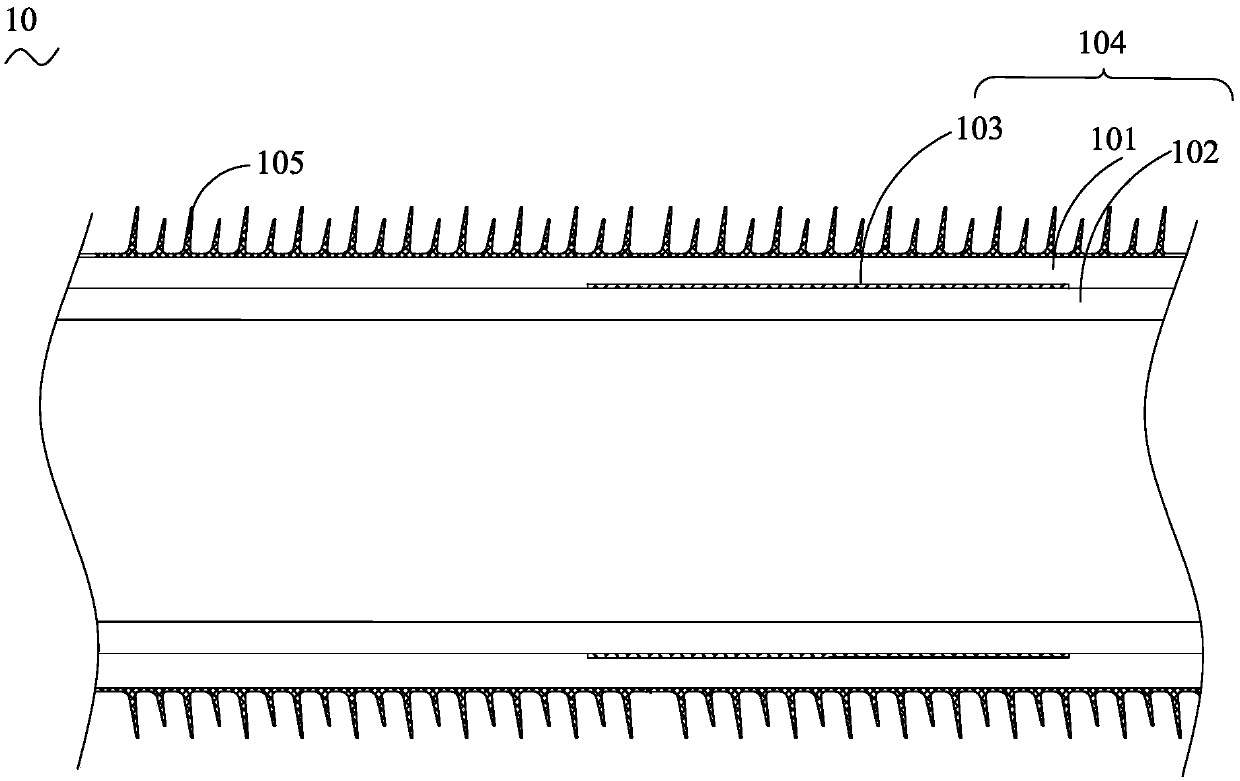

[0047] Such as figure 1 As shown, an embodiment of the composite insulator of the present invention includes an insulating tube 104 and an umbrella shed 105 coated on the outside of the insulating tube 104. The insulating tube 104 includes a winding layer 102, a semiconductor material layer 103 and a winding layer 101. The winding layer 102 is far away from the umbrella...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com