Multi-tube-bank superheater of waste heat boiler

A waste heat boiler and superheater technology, used in steam superheating, lighting and heating equipment, steam generation and other directions, can solve the problems of high design difficulty of heating surface, poor operation safety, etc. The effect of improving safety and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

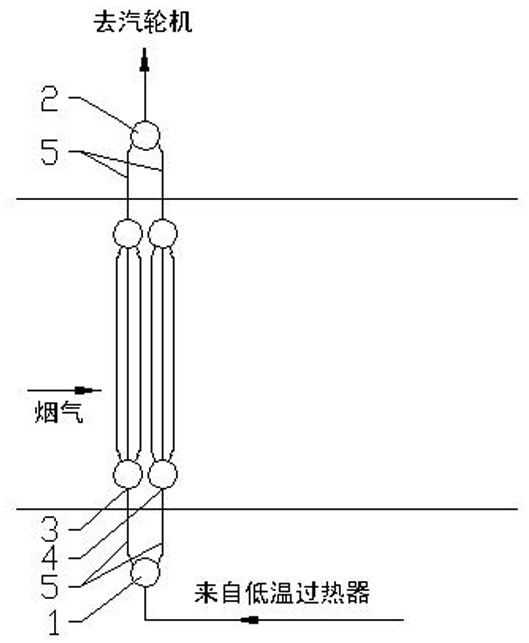

Image

Examples

Embodiment 1

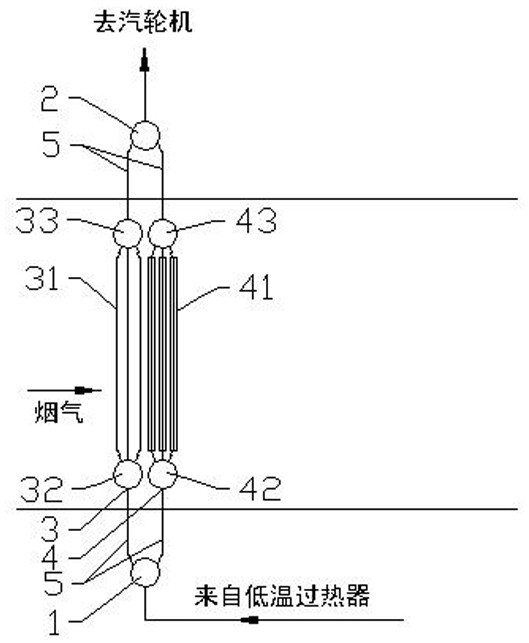

[0022]Example 1: As attachedfigure 2 , AttachedFigure 4 As shown, the present invention includes a steam inlet header 1, a tube group outlet header 2, and a first tube panel 3 and a second tube panel 4 arranged in parallel between the steam inlet header 1 and the tube group outlet header 2. A tube panel 3 is located on the front side of the second tube panel 4 with respect to the flue gas flow;

[0023]The first tube panel 3 includes a first tube panel inlet header 32 connected to the steam inlet header 1 through a connecting tube 5, and a first tube panel outlet header 33 connected to the tube group outlet header 2 through the connecting tube 5, arranged in Three rows of first heating surfaces 31 between the first tube panel inlet header 32 and the first tube panel outlet header 33, the first heating surface 31 uses light tubes;

[0024]The second tube panel 4 includes a second tube panel inlet header 42 connected to the steam inlet header 1 through a connecting tube 5, and a second tub...

Embodiment 2

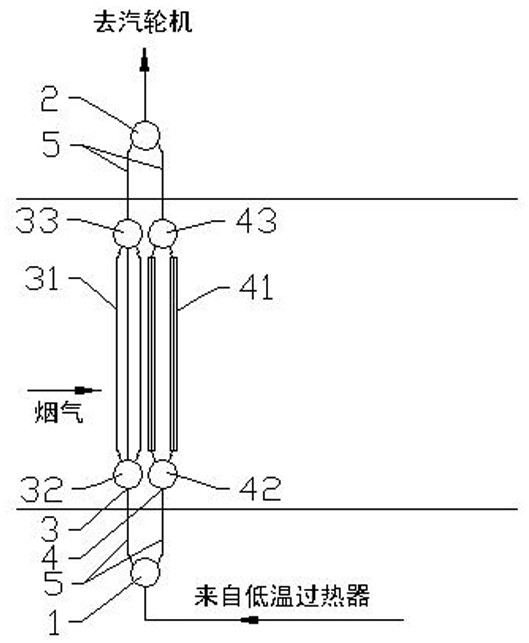

[0030]Example 2: As attachedimage 3 , AttachedFigure 4 As shown, the present invention includes a steam inlet header 1, a tube group outlet header 2, and a first tube panel 3 and a second tube panel 4 arranged in parallel between the steam inlet header 1 and the tube group outlet header 2. A tube panel 3 is located on the front side of the second tube panel 4 with respect to the flue gas flow;

[0031]The first tube panel 3 includes a first tube panel inlet header 32 connected to the steam inlet header 1 through a connecting tube 5, and a first tube panel outlet header 33 connected to the tube group outlet header 2 through a connecting tube 5, arranged Three rows of first heating surfaces 31 between the first tube panel inlet header 32 and the first tube panel outlet header 33, and the first heating surface 31 adopts light tubes;

[0032]The second tube panel 4 includes a second tube panel inlet header 42 connected to the steam inlet header 1 through a connecting tube 5, and a second tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com