Method for detecting heat resistance of hot melt adhesive for sealing

A technology of heat resistance and detection method, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., to achieve the effect of simple and fast operation, quality assurance and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below through specific preferred embodiments, but the present invention is not limited to the following embodiments.

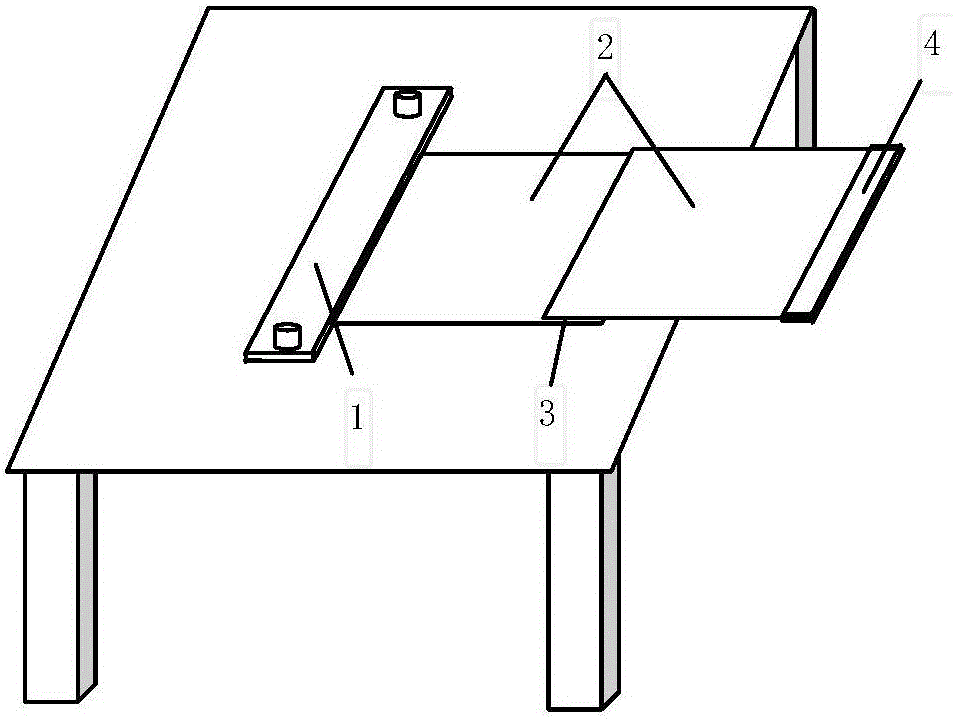

[0038] The method for detecting heat resistance of hot melt adhesive for sealing of the present invention includes the following steps:

[0039] 1) Set the hot melt adhesive heat resistance temperature standard, which is consistent with the actual maximum transportation and storage environment temperature. By continuously increasing the temperature and keeping the temperature constant for 2 hours, it can simulate the actual environmental temperature increase process and determine the accurate heat resistance temperature;

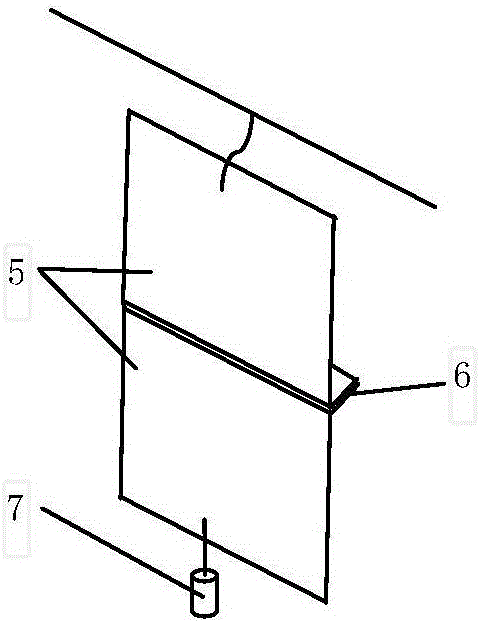

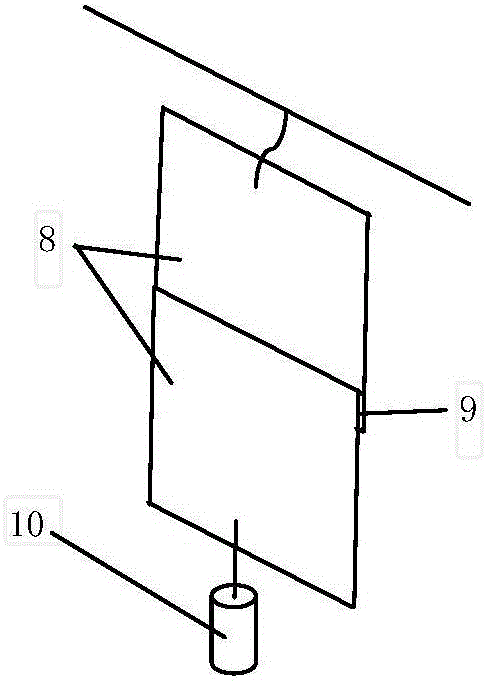

[0040] 2) Set each peeling shear direction and the weight of the weight used to simulate the actual force during transportation and storage;

[0041] 3) Set the size and shape of each cardboard and the position and amount of spraying hot melt adhesive to ensure that it is consistent wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com