Three-dimensional physical model test device

A model test device and three-dimensional physical technology, which are applied in soil material testing, material inspection products, etc., can solve the problems of inability to realize inclined mining, inconsistency in the excavation process, and large gaps, and achieve rock mass excavation. The simulation test results are accurate and reliable, the overall structure is firm, and the inclination angle is suitable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Example 1: Roadway Excavation Simulation

[0061] The method for simulating roadway excavation by using the above-mentioned three-dimensional physical model test device comprises the following steps:

[0062] Step 1: Construct the reaction frame A0 and build the model device:

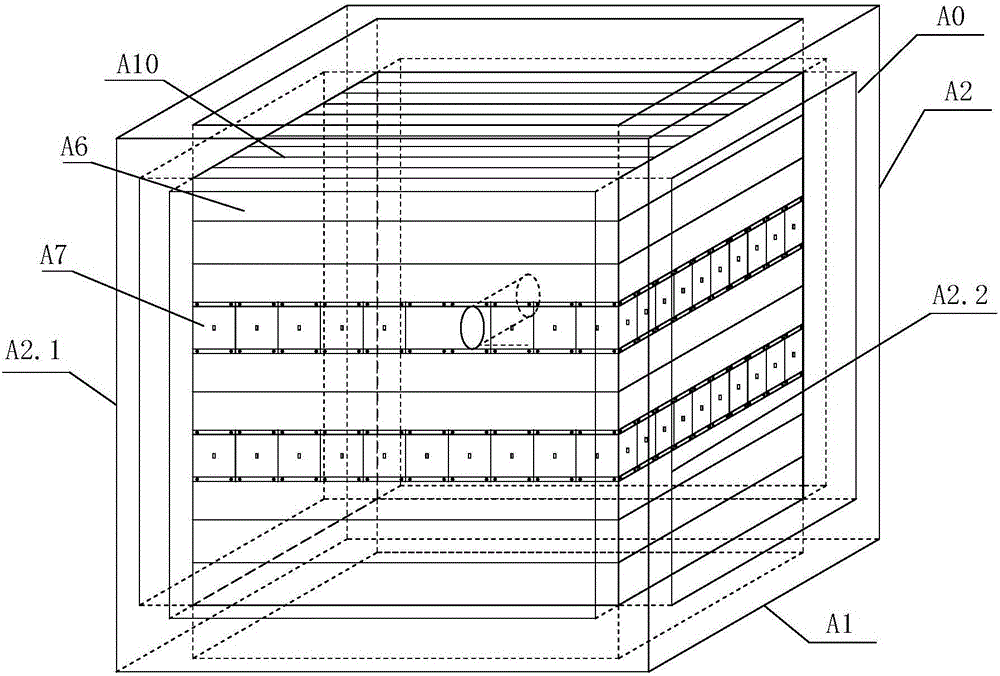

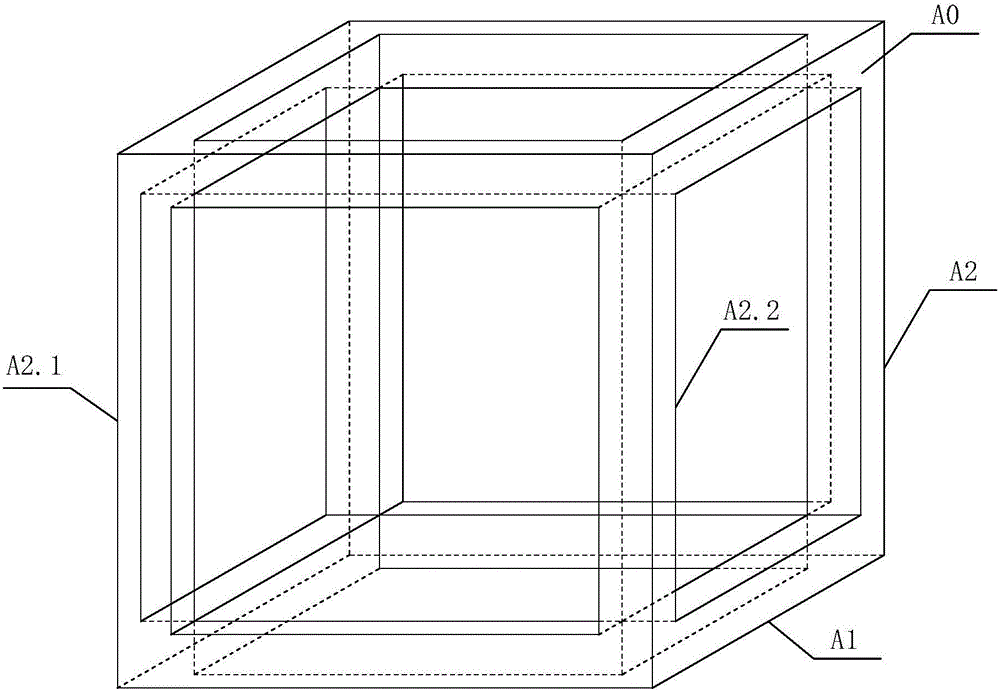

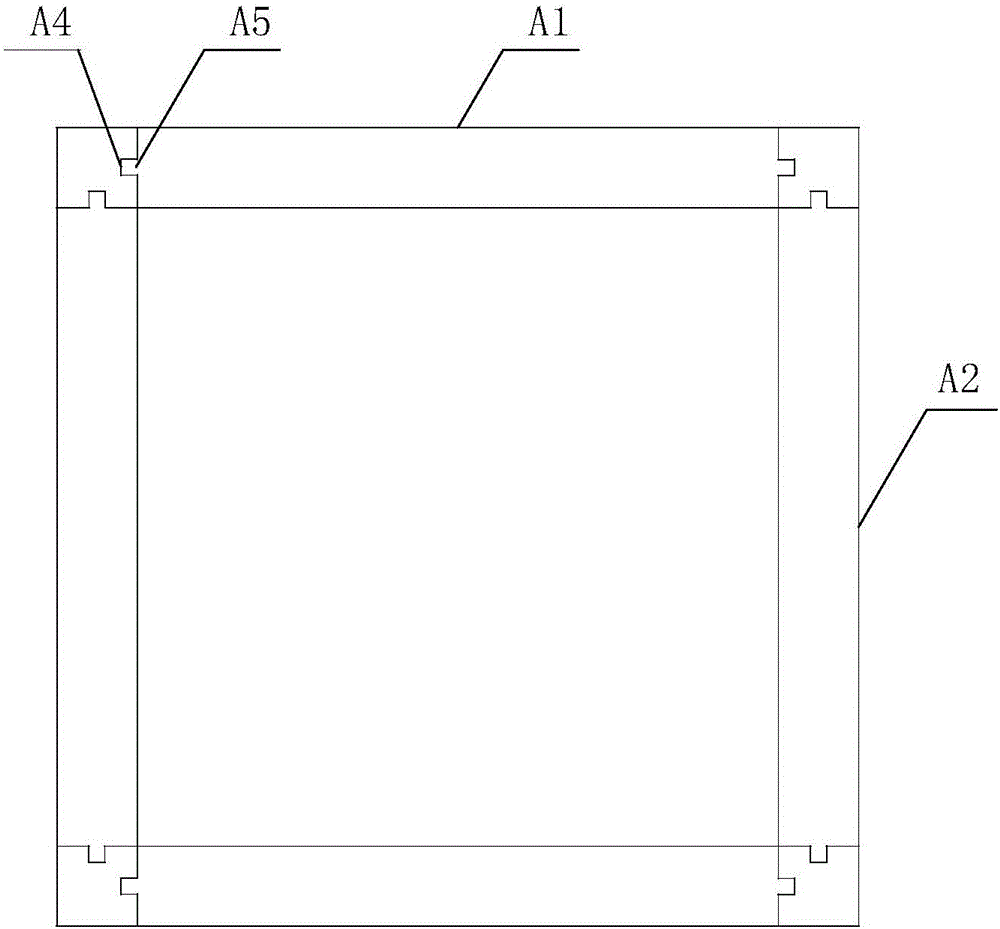

[0063] To construct the reaction force frame A0, a plurality of parallel rectangular large steel plates A6 with a horizontal plane angle α are arranged on the cubic frame surface A11, and a plurality of parallel rectangular small steel plates A7 are arranged between two rectangular large steel plates A6.

[0064] A rock mass model A12 is set in the reaction frame A0, and a vertical loading system A15, a horizontal front-back loading system A14, and a horizontal left-right loading system A13 are installed.

[0065] Set the vertical loading system A15, the horizontal front-back loading system A14, and the horizontal left-right loading system A13 to load pressure on the rock mass model A12.

[006...

Embodiment 2

[0075] Example 2: Simulation of coal seam horizontal and inclined mining

[0076] The method for simulating horizontal coal seam mining by using the above-mentioned three-dimensional physical model test device comprises the following steps:

[0077] Steps 1-3: Consistent with the simulated roadway excavation in Embodiment 1. Until the excavation of the first roadway is completed.

[0078] Step 4: Remove the next small rectangular steel plate A7 adjacent to the removed first small rectangular steel plate A7.

[0079] Step 5: Repeat steps 2 to 4 to complete the working face advancement simulation.

[0080] In this embodiment, the adjacent small rectangular steel plates A7 are sequentially removed, so that a full recovery simulation can be performed on a simulated working face between two large rectangular steel plates A6 on the cube frame surface A11.

[0081] If necessary, the above steps can be repeated for another row of rectangular small steel plates A7 between the other ...

Embodiment 3

[0083] Embodiment 3: mining simulation of metal ore caving method

[0084] Steps 1-4: Consistent with the simulated roadway excavation in Embodiment 1; until the excavation of the first roadway is completed. The following steps are then taken to simulate metal ore caving mining production:

[0085]Step 5: Manipulate the vertical loading system A15, the horizontal front-back loading system A14, and the horizontal left-right loading system A13, control and generate vibration, and simulate an on-site blasting of a working face.

[0086] The jacks that control each loading system cooperate with each other to simulate an on-site blasting, which is the "ore falling" in actual production.

[0087] Step 6: directly discharge the rock mass model A12 fragments formed by the vibration.

[0088] The rock mass model A12 fragments formed by the vibration are the "ores" that have collapsed in the simulation of actual production; after the "ores" are discharged, this simulation is completed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com