Data processing method for realizing machine tool robustness thermal error compensation of wide-range environment temperature

An ambient temperature and data processing technology, applied in computer control, instruments, simulators, etc., can solve problems such as reducing the robustness of thermal error prediction models, the prediction robustness of models, and the impact of time series models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific examples.

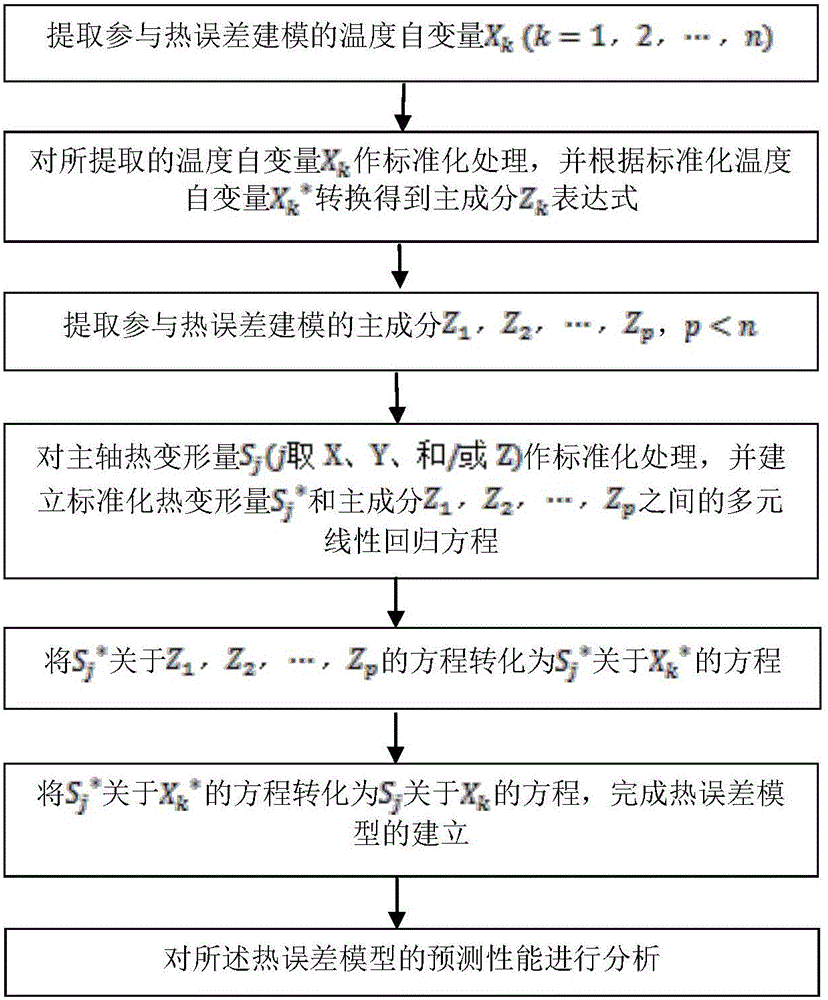

[0067] see figure 1 , a data processing method for realizing thermal error compensation of machine tool robustness in a wide range of ambient temperature, the steps are as follows:

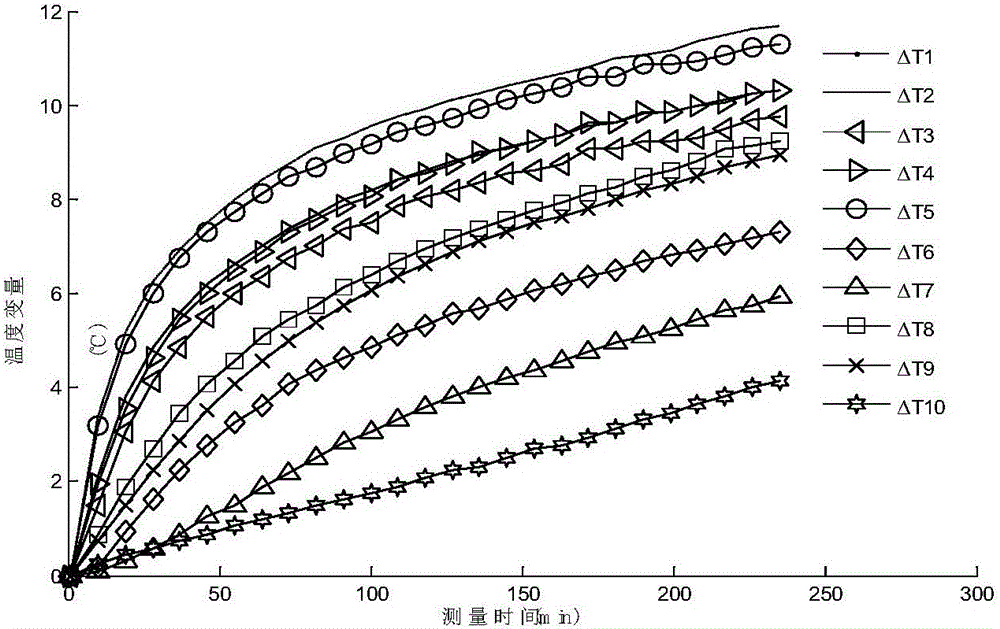

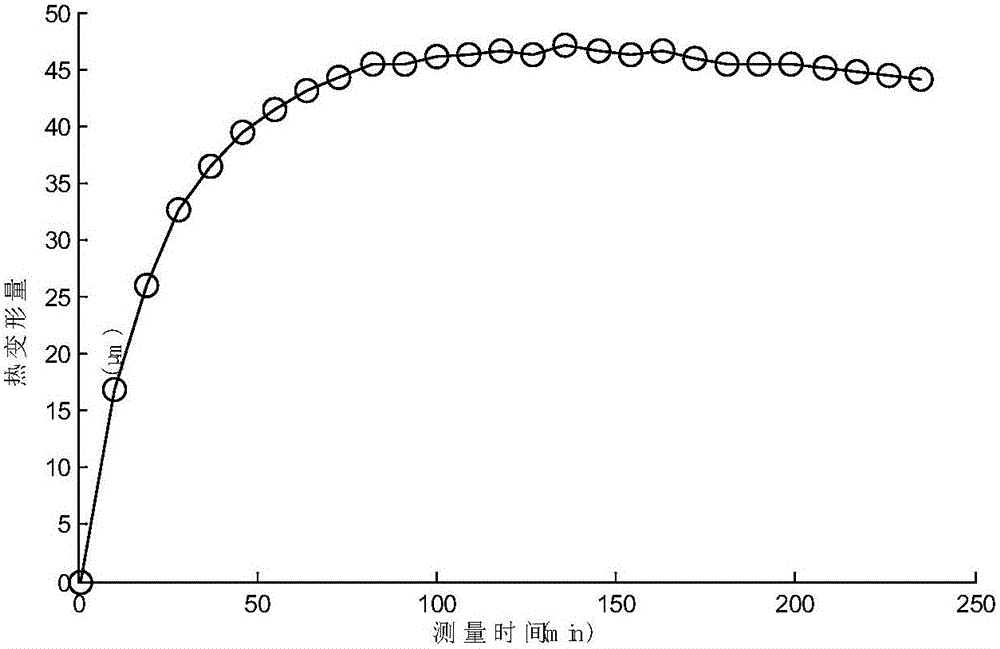

[0068] Step 1: Obtain the temperature variable ΔT of the machine tool i and spindle thermal deformation S j , where i=1, 2, . . . , m.

[0069] The m refers to the number of temperature variables. Said j refers to the axial direction of the machine tool spindle, and j is X, Y, and / or Z. X, Y, and Z respectively represent the X axis of the machine tool spindle, the Y axis of the spindle, and the Z axis of the spindle.

[0070] by the temperature variable ΔT i and spindle thermal deformation S j The correlation relationship to obtain the temperature independent variable X k , k=1, 2, . . . , n.

[0071] The temperature argument X k It is used to esta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com