Novel automatic screwing device

An automatic and screw technology, applied in the direction of electromechanical devices, electric components, manufacturing motor generators, etc., can solve the problems of affecting the quality of the motor, high labor intensity, uneven force, etc., to achieve a small footprint, reduce labor intensity, avoid uneven force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

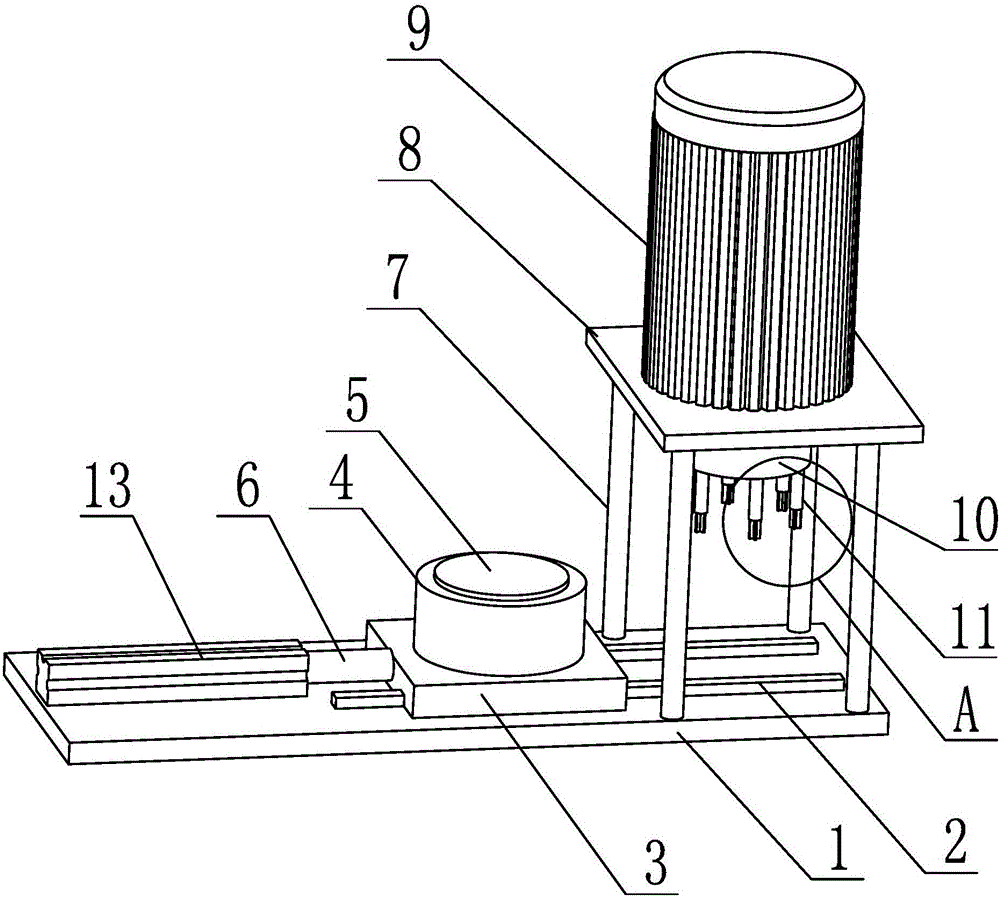

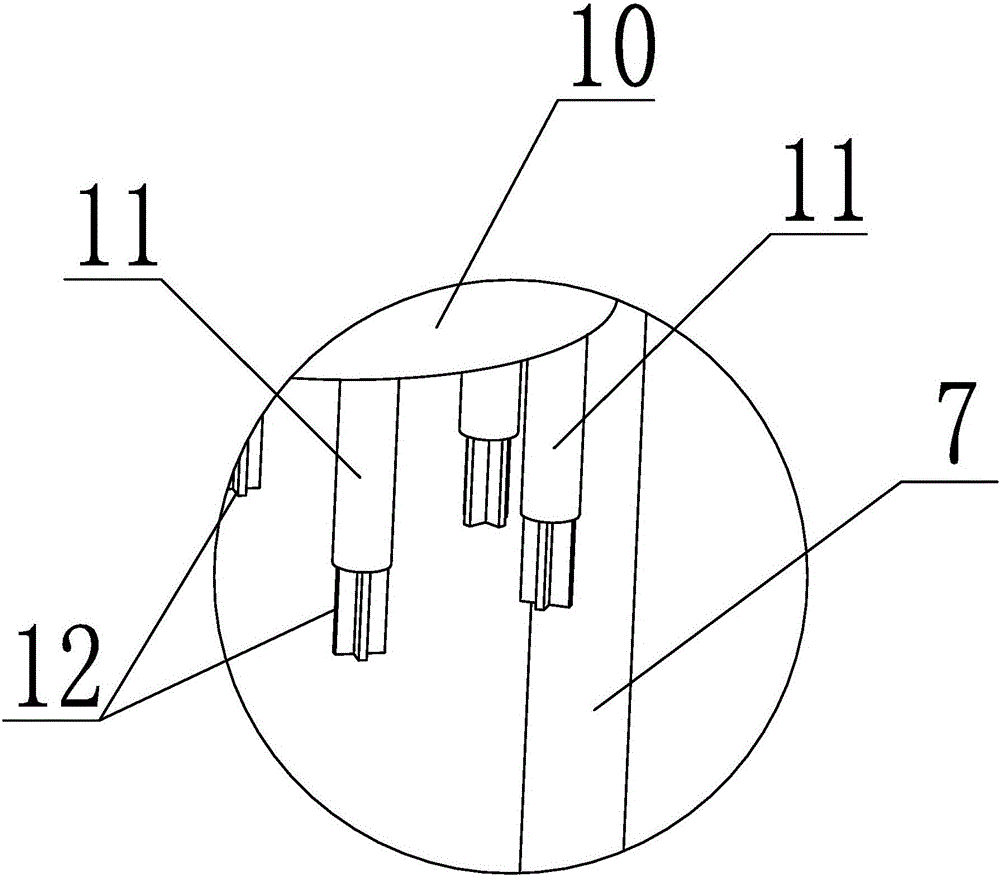

[0010] The present invention is described in further detail now in conjunction with accompanying drawing. The accompanying drawings are simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so that they only show the components relevant to the present invention.

[0011] see figure 1 and figure 2 , a new type of automatic screwing device, including a base plate 1, a guide rail 2, a mobile base 3, an operating table 4, a fixed column 7, a motor 9 and a cylinder 13, the guide rail 2 and the cylinder 13 are fixed on the base plate 1, and the cylinder The top of the cylinder mandrel 6 of 13 is fixed on the mobile base 3, and the mobile base 3 can slide on the bottom plate 1 and the guide rail 2 under the drive of the cylinder 13, and the operating platform 4 is fixed on the mobile base 3, and the operated The top of platform 4 is provided with boss 5, and described base plate 1 is fixed with four fixed columns 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com