Conductor molding device and method

A kind of wire, one-sided technology, applied in the direction of electromechanical devices, the shape/style/structure of winding conductors, the manufacture of motor generators, etc., can solve the problems of poor forming accuracy and poor forming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Next, modes for implementing the present invention will be described with reference to the drawings.

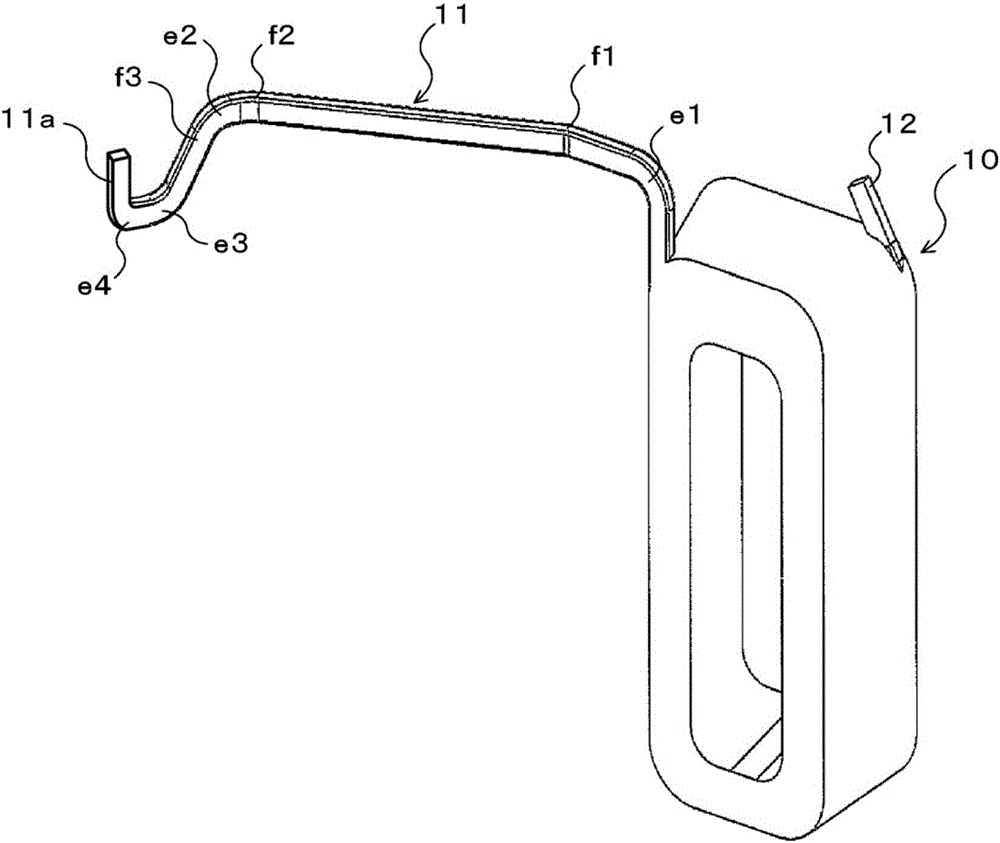

[0050] figure 1 It is a perspective view showing the coil 10 formed by the coil end shaping|molding apparatus which is a wire shaping|molding apparatus of this invention. The coil 10 shown in this figure is included in a stator (not shown) for a motor, and the stator for a motor is configured together with a rotor not shown, and is used as a driving source and / or a generator of an electric vehicle or a hybrid vehicle, for example. three-phase AC motors. In addition, the motor stator includes a plurality of coils 10 and a not-shown stator core. The stator core has: a plurality of split cores arranged in an annular shape; and a fixing ring for fixing the plurality of split cores. Each coil 10 is attached to a corresponding split iron core via an insulating member (not shown), and the motor stator (stator iron core) is covered with molding resin such as thermosetting re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com