Weaving process of wig

A craft and wig technology, which is applied in the wig industry, can solve problems such as affecting the wearing effect, lack of security, and difficulty in shaping, so as to improve the wearing effect, improve the sense of security, and avoid loosening and falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

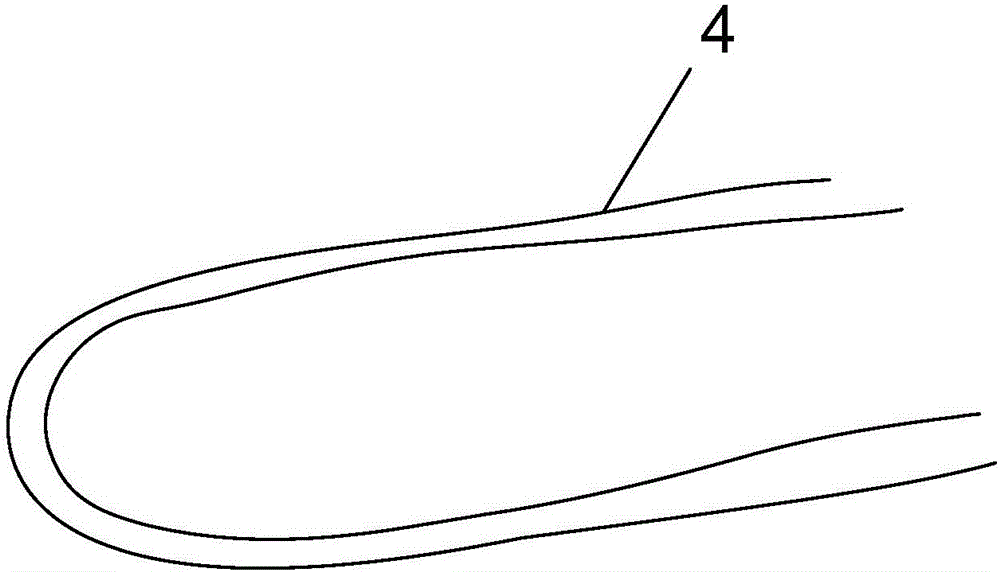

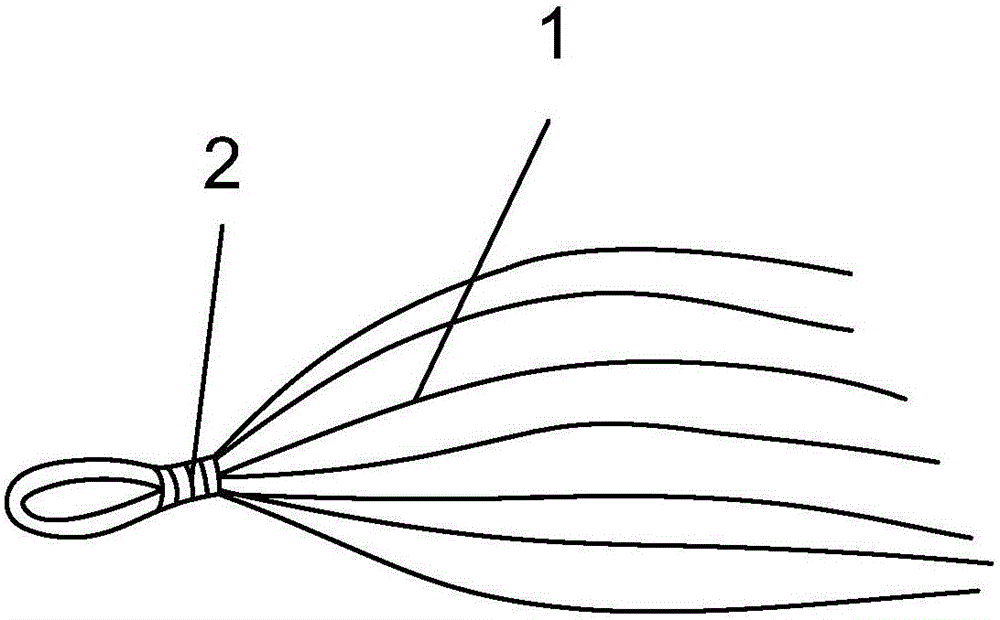

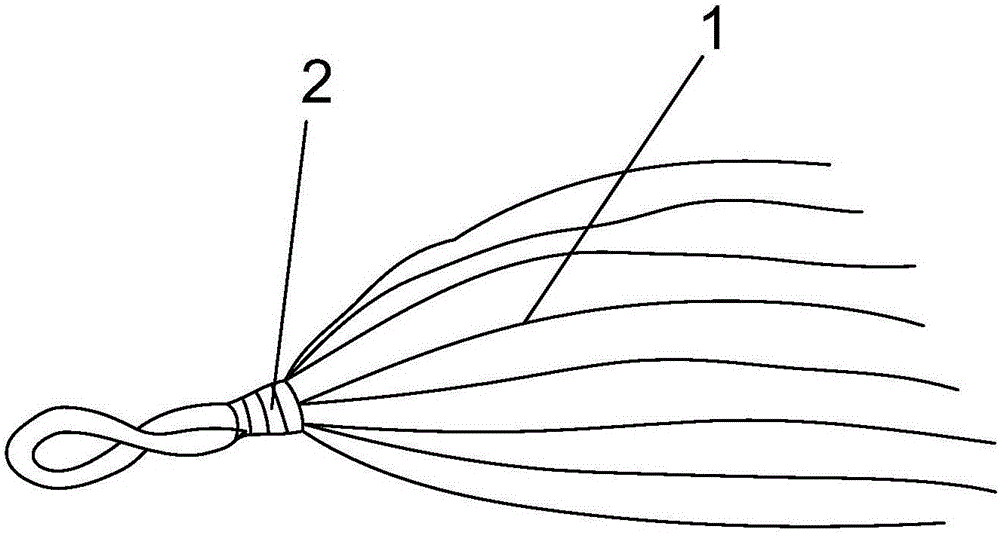

[0033] A weaving process for a wig, the weaving process includes the following steps: twisting the folded ends of a hair handle 1 for multiple turns, and binding the folded ends with an elastic thread 2 so that the folded ends of the hair handle form a closed circle; The hook part of the crochet needle passes through the braid of the base body so that the hook part is exposed outside the braid; the hook part of the crochet hook is hooked to the closed ring at the end of the hair handle; The closed circle of the hair handle goes through the braid; the hook of the crochet needle passes through the closed circle to hook the other end of the hair handle; the crochet needle exits the closed circle, and at the same time the other end of the hair handle passes through the closed circle to bind the braid; both hands Break off the hair handle, push the two parts of the hair handle to the outside of the hands, retreat the elastic thread to the braid and cling to the braid; tidy the hair ...

Embodiment 2

[0036] The difference from Embodiment 1 is that a section of braid is made at the end of the hair handle folded in half, and then the braid is bound with an elastic cord. Wherein, the braid of the base body is braided by three strands of hair. All the other steps are the same as in Example 1.

Embodiment 3

[0038] The difference from Embodiment 1 is that a section of braid is made at the end of the hair handle folded in half, and then the braid is bound with an elastic cord. Among them, the braid of the base body is braided by four strands of hair. All the other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com