Welding fixture for titanium, zirconium and titanium zirconium alloy electrode blocks

A technology of alloy electrodes and welding fixtures, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high clamping labor intensity, complex structure of welding fixtures, and high manufacturing costs, and achieve compact structure and low cost. Low, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

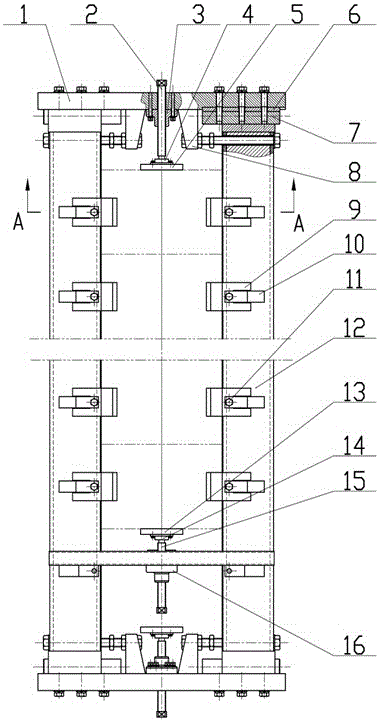

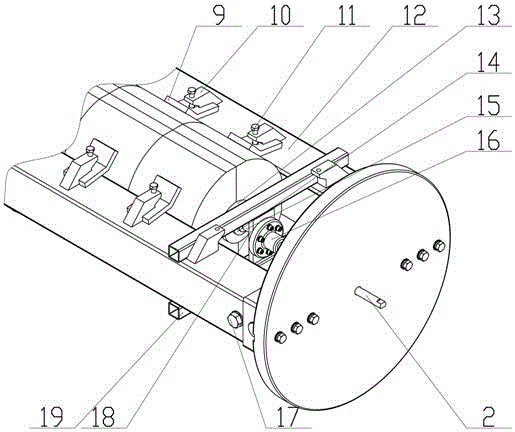

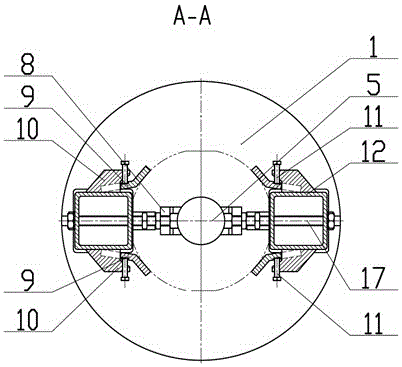

[0019] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0020] see figure 1 , 2 , 3, 4. The present invention is a welding jig for electrode blocks of titanium, zirconium and their alloys, a welding jig for electrode blocks of titanium, zirconium and their alloys, including fixed tops mounted on support plates at both ends of the jig The clamping device, the radial guide adjustment and fixing device composed of the clamping beam and the adjusting part; the clamping device and the movable clamping device composed of the clamping beam and the clamping part; Two clamping beams 12 are arranged between the support plates 1; the support plates 1 at the upper and lower ends are all provided with a fixed top tightening screw sleeve 3, and a fixed top tightening screw 2 is arranged in the fixed top tightening screw sleeve 3; The inner end of the jacking screw 2 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com