Cold-rolling mill multivariate strip shape control method based on constrained optimization algorithm

A technology of constrained optimization and flatness control, which is applied in the field of metallurgical rolling and can solve problems such as complex modeling of the flatness control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

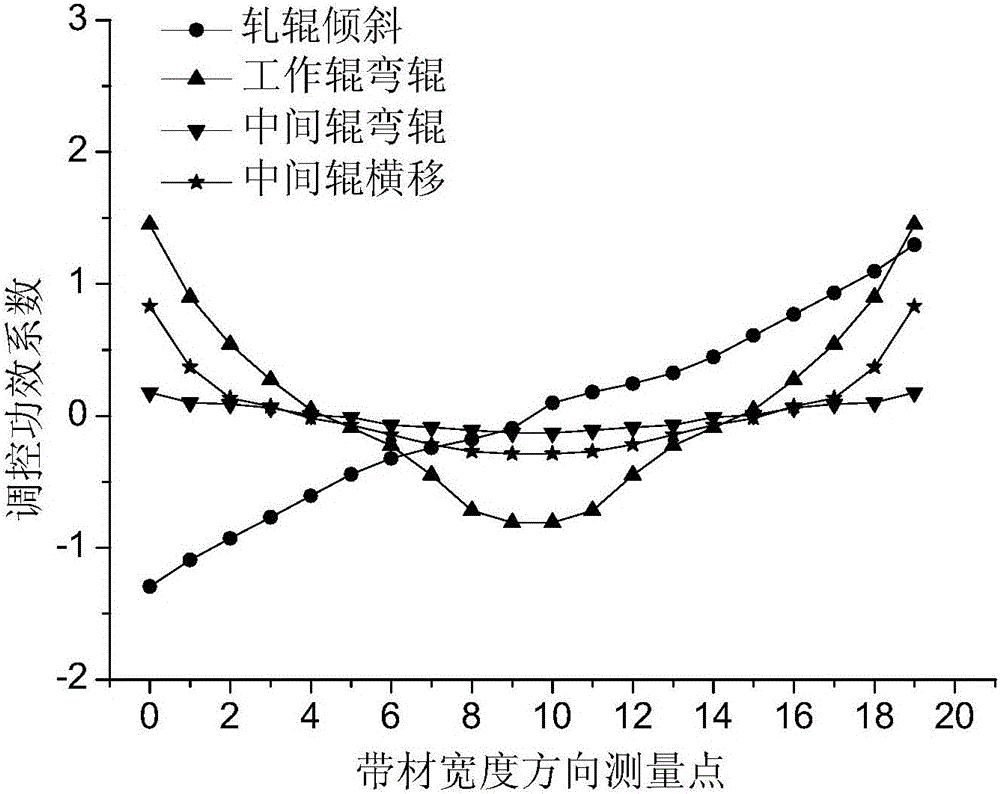

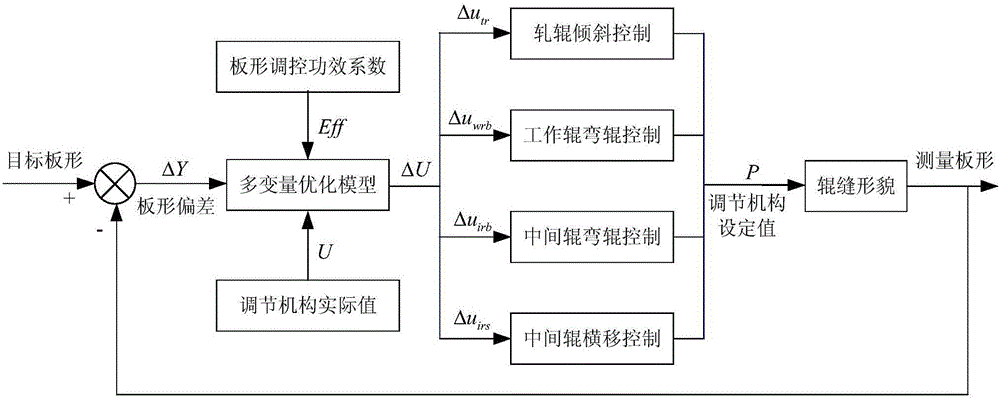

[0037] Embodiment 1: This embodiment 1 discloses the processing process of the multi-variable flatness optimization algorithm in the last stand flatness closed-loop control system of a 1450mm five-stand tandem cold rolling mill. The plate shape adjustment mechanism includes roll tilting, positive / negative bending of work rolls, positive bending of intermediate rolls and lateral movement of intermediate rolls. The main control parameters and rolling parameters are shown in Table 1.

[0038] Table 1 Main parameters of rolling mill

[0039]

[0040]

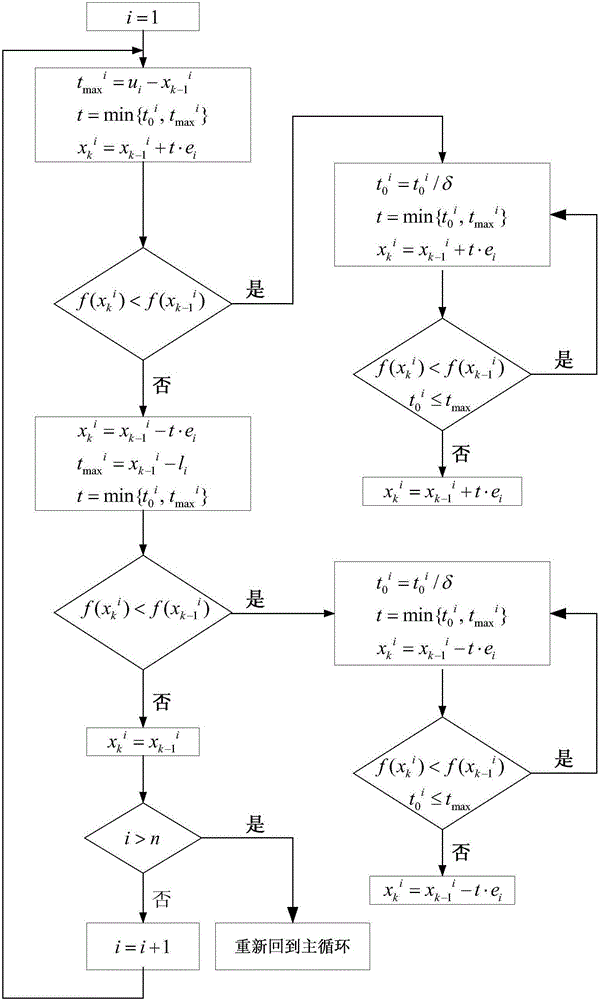

[0041] The control method of the present invention formulates an optimization model for solving the optimal adjustment amount of each plate shape adjustment mechanism through mathematical modeling, and designs a multi-variable optimization algorithm with global convergence around the optimization model; the multi-variable The optimization algorithm transforms the multivariable plate shape optimization problem with constraints ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com