Modified shell punching die

A technology for stamping dies and shells, which is applied in the field of improved shell stamping dies, which can solve the problems of cumbersome procedures, troublesome people, difficult shell edge reverse-wrapping stamping and forming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

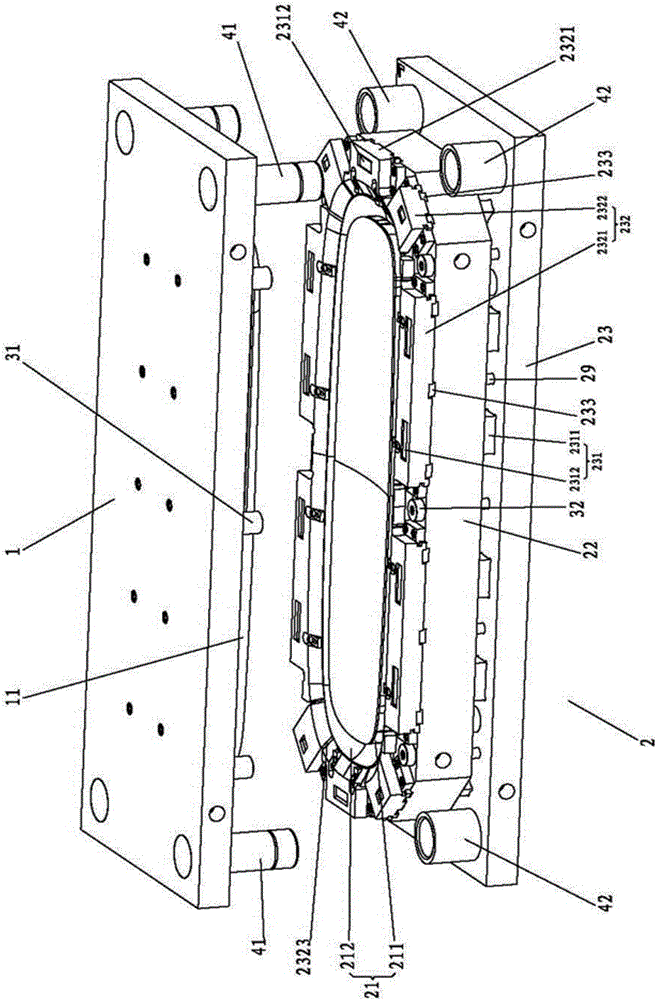

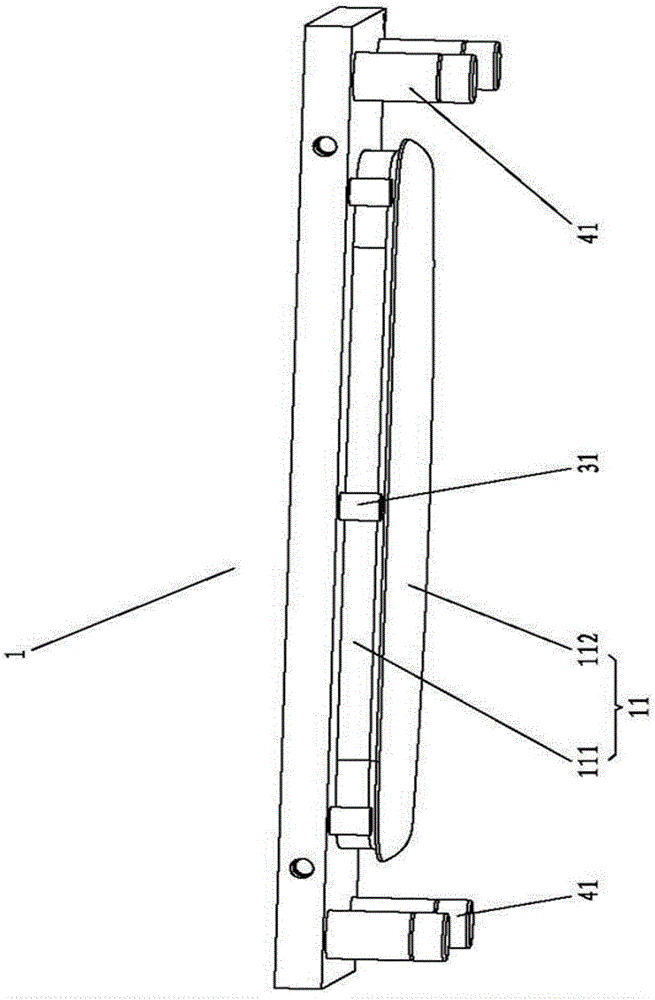

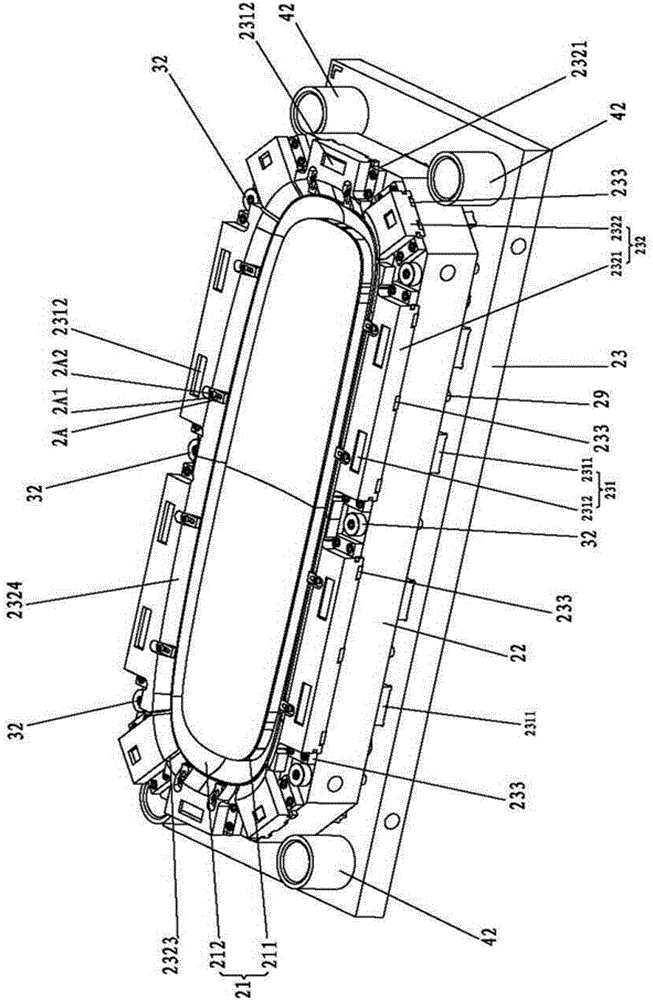

[0059] A stamping die of a shell of the present invention, such as Figure 1-12 As shown, it includes an upper mold 1 at the top and a lower mold 2 at the bottom. The upper die 1 has a punch 11 facing downward, and the lower die 2 has a die 21 with an opening facing upward. The specific structure can be that the inner surface of the die 21 is covered with a soft rubber layer, which can prevent the die 21 from scratching the shell The lower mold 2 includes the first layer, the second layer, the third layer and the fourth layer from top to bottom; As the mold wall block 212 of the cavity wall of the concave mold 21 outside the bottom block 211, the mold bottom block 211 constitutes the first layer, the mold wall block 212 has a mold wall bottom plate 2121 blocked at the lower end, the mold wall block 212 and the mold wall bottom plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com