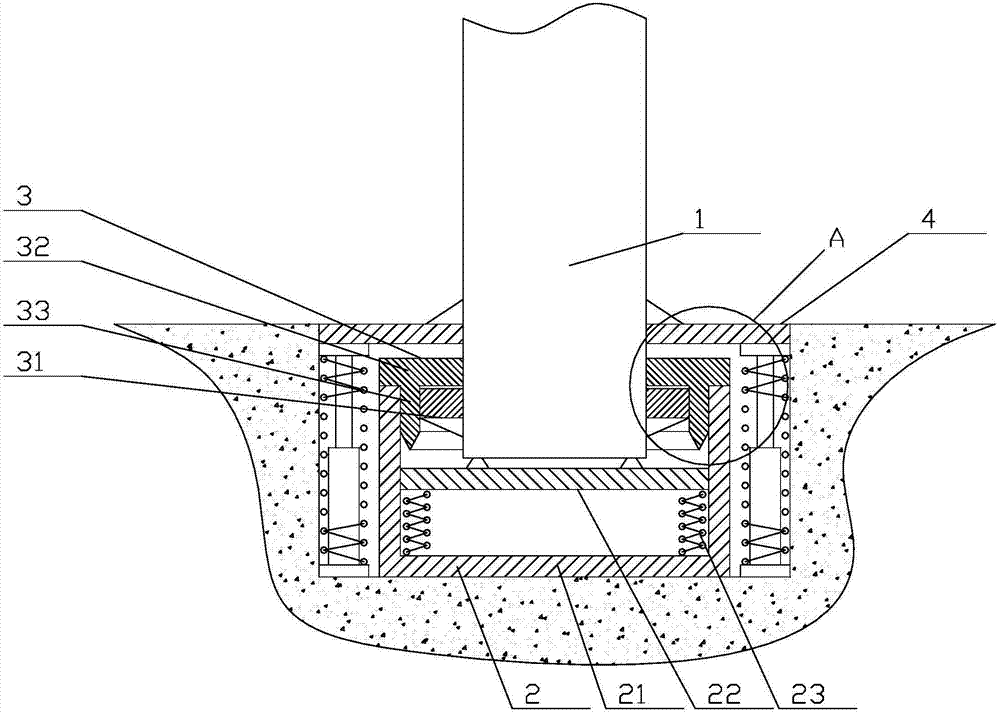

Base of a punching machine and its installation method

An installation method and punching machine technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of upper die offset, workpiece quality impact, etc., achieve the effect of small rebound, good integrity, and avoid small offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

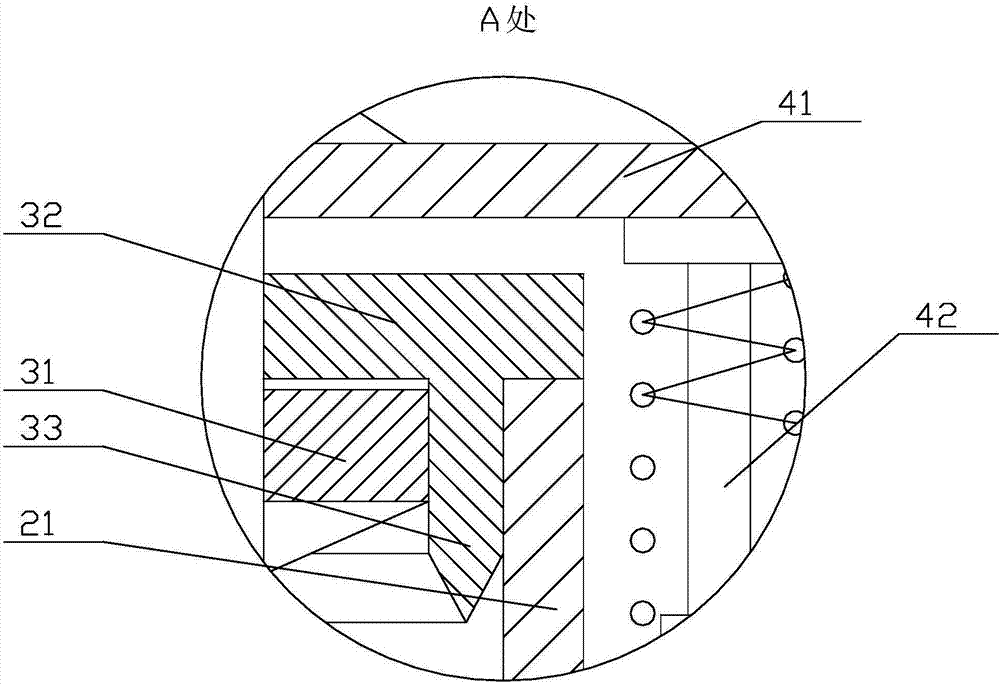

Method used

Image

Examples

Embodiment 1

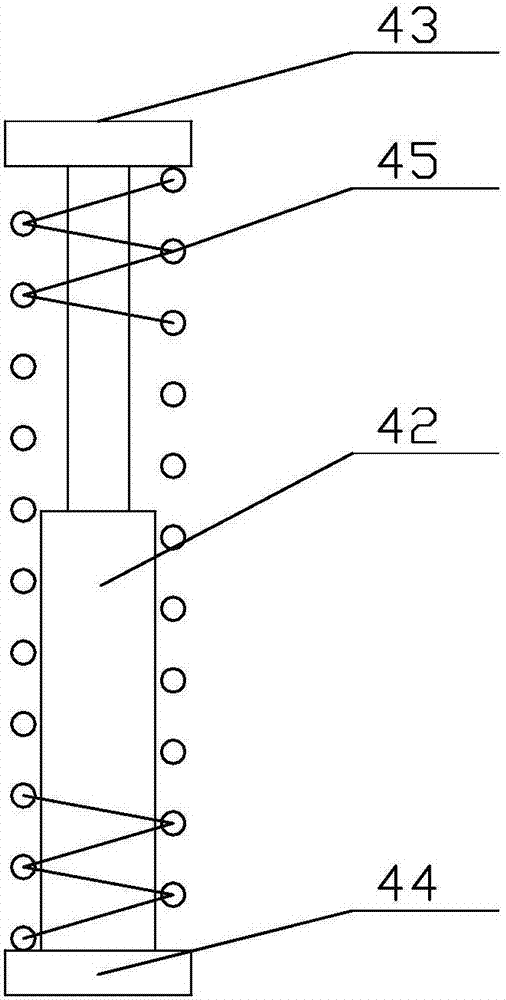

[0042]Embodiment 1: The damping rod 42 includes an inner rod body 421, an outer rod body 422 and a sealing plate 423, the inner rod body 421 is hollow with an open bottom, and the outer rod 422 is hollow with an open top. The inner rod body 421 is slidably connected to the top opening of the outer rod body 422, the sealing plate 423 is fixedly connected to the bottom opening of the inner rod body 421, and at least one flow hole is opened on the sealing plate 423, and the outer rod body 422 Filled with hydraulic oil. In this way, when the inner rod body and the outer rod body move relative to each other, the hydraulic oil flowing through the flow hole 1 will provide sufficient damping effect, so as to effectively slow down and resist rebound.

Embodiment 2

[0043] Embodiment 2: The damping rod 42 includes a fixed rod pile 424, a movable rod body 425 and a piston plate 426. The fixed rod pile 424 is hollow and has a sliding hole on the top, and the movable rod body 425 is penetrated in the In the sliding hole, the piston plate 426 is slidably connected in the fixed rod pile 424, the piston plate 426 is fixedly connected to the bottom end of the movable rod body 425, and at least one flow hole 2 is opened on the piston plate 426, and the fixed The pole pile 424 is filled with hydraulic oil. In this way, when the movable rod body performs telescopic movement relative to the fixed rod pile, the hydraulic oil flowing through the flow hole 1 will provide sufficient damping effect, so as to effectively slow down and resist rebound.

[0044] Follow these steps:

[0045] 1) Preset installation position: dig a deep pit on the ground to accommodate the base, and level and compact the bottom of the pit;

[0046] 2) Install the buffer assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com