Support-rod-braked trundle

A technology of brake feet and brake levers, applied in casters, wheels, transportation and packaging, etc., can solve the problems of positioning failure, easy torque damage to the wheel frame, affecting braking reliability, etc., and achieves convenient braking operation and control. The effect of dynamic stability and increased braking reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

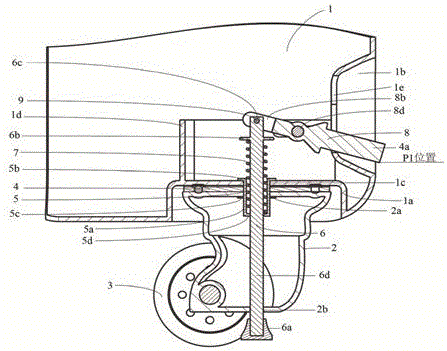

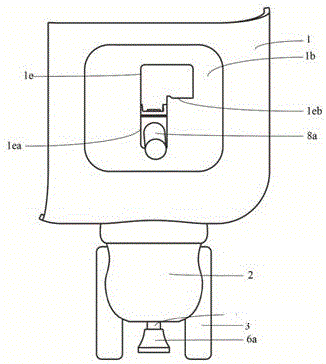

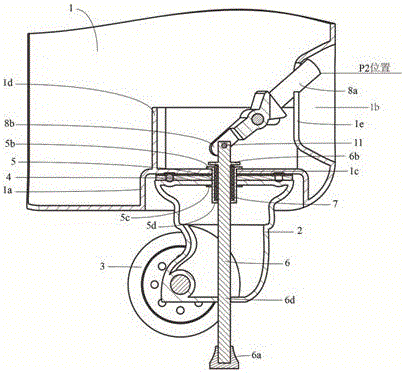

[0029] like Figure 1 to Figure 5 , a strut brake caster, including a wheel base 1, a wheel frame 2, a wheel body 3, a bearing 4, a connecting sleeve 5, a braking rod 6, a spring 7, a pulling member 8, a positioning groove 1e, and a pin shaft groove 1f .

[0030] The wheel base 1 is the lower corner of the box body, with an upper protrusion 1a on the bottom surface and a side concave 1b on one side surface. There is a round seat hole 1c in the middle of the upper protrusion 1a, and a U-shaped frame 1d whose opening points to the side concave at the upper end. The pin shaft groove 1f is a horizontal slot hole respectively opened on the two wings of the U-shaped frame 1d; the positioning groove 1e is an inverted L-shaped through-hole groove provided on the side recess 1b.

[0031] The wheel frame 2 is connected to the wheel body 3 on one side of the lower end. The upper middle and lower ends of the wheel frame 2 are respectively provided with a coaxial upper hole 2a and a lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com