A control method for a continuously variable speed tractor control system

A control system and control method technology, applied in the direction of mechanical equipment, combustion engines, internal combustion piston engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

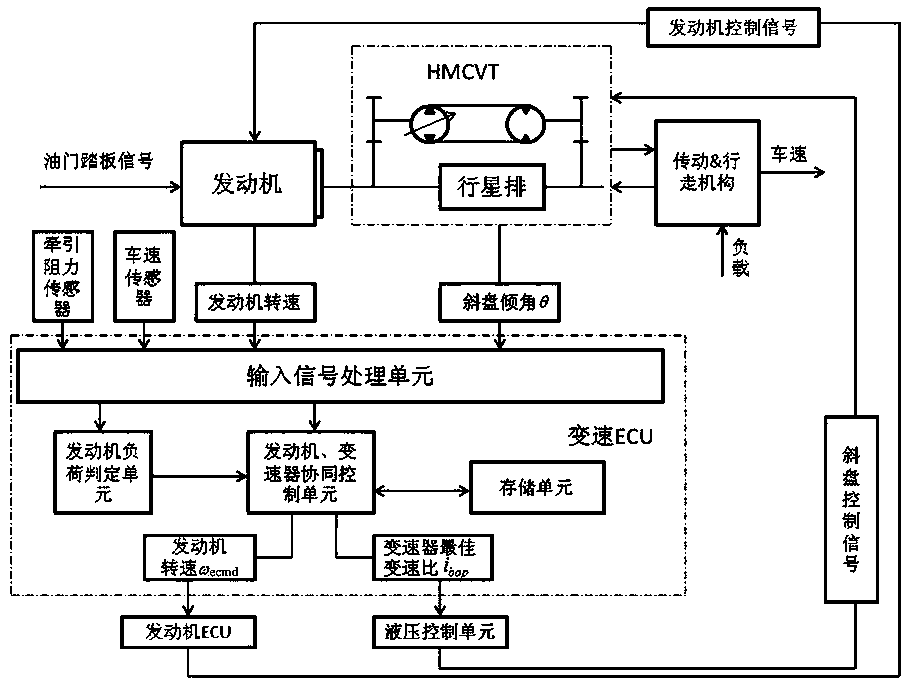

[0041] Specific embodiment: the present invention takes a certain type of Dongfanghong 400-horsepower wheeled tractor equipped with a hydraulic-mechanical continuously variable transmission as the object, and the main parameters of the system are: tractor vehicle mass m=7760kg, tractor main transmission ratio =36.348, transmission ratio The range is 0~2.24, the tractor driving wheel radius r d =0.9046m, engine rated power N e0 =228kw, the maximum output power of the engine =294kW, engine rated speed =2100(r / min), the maximum engine speed =2300(r / min), maximum engine torque =1200N·m, maximum traction force =80kN.

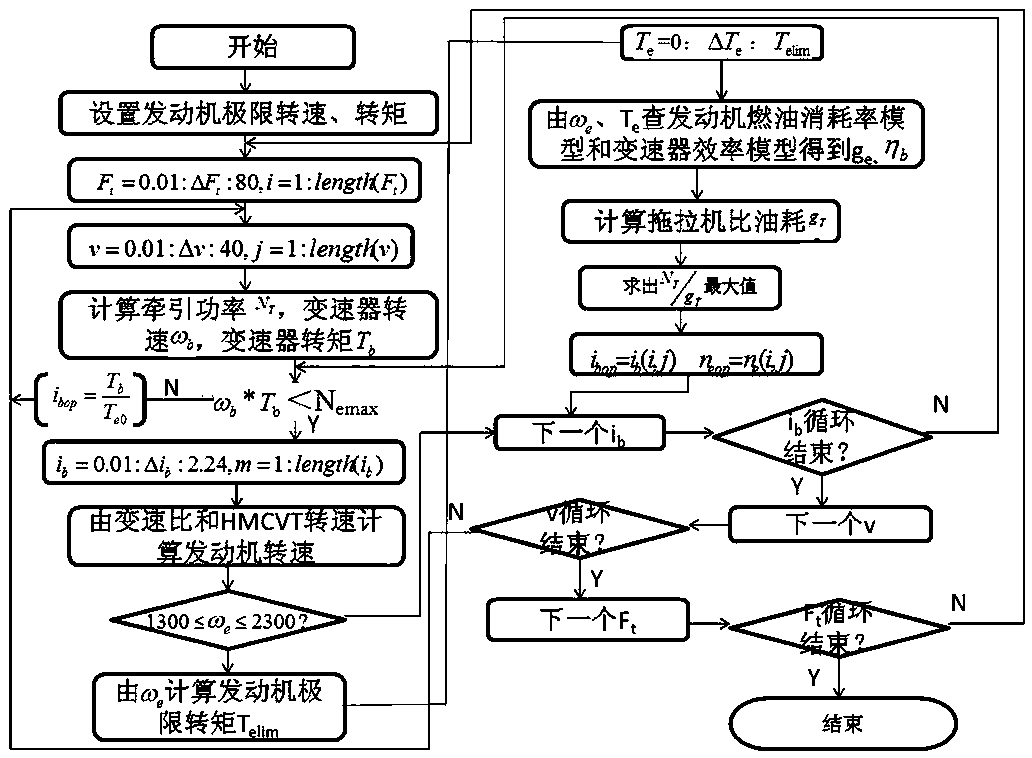

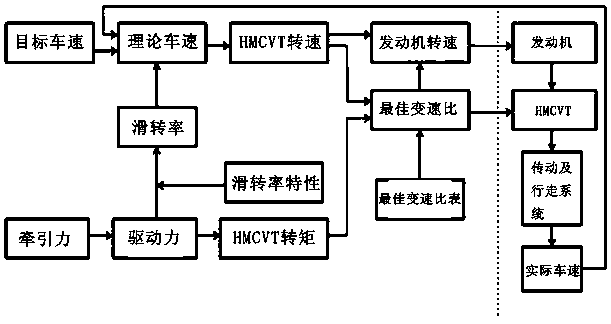

[0042] like figure 1 As shown, a continuously variable tractor tractor productivity-economic comprehensive optimum transmission ratio optimization calculation method, the steps are as follows:

[0043] (1) Set the limit speed and torque of the engine and the range of the HMCVT transmission ratio. The speed of the wheeled tractor in the field is mainly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com