Device and method for preventing steering capsizing

A technology for turning rudder and hull, applied in the field of ships, can solve problems such as force and moment increase the difficulty of ship attitude control, ship capsize, etc., and achieve the effect of being beneficial to control, improving safety, and solving easy capsizing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

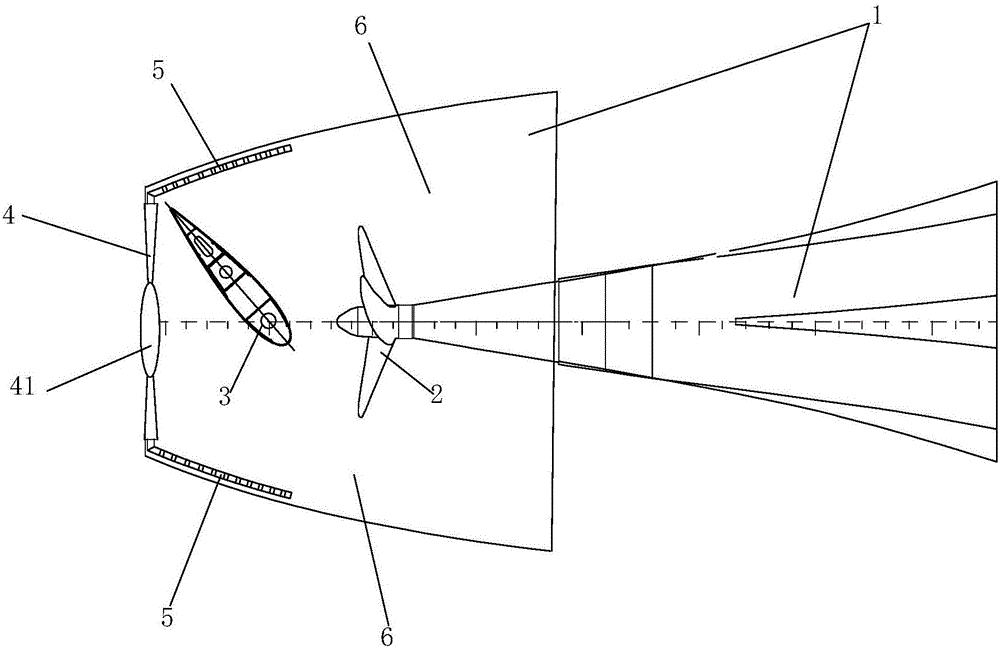

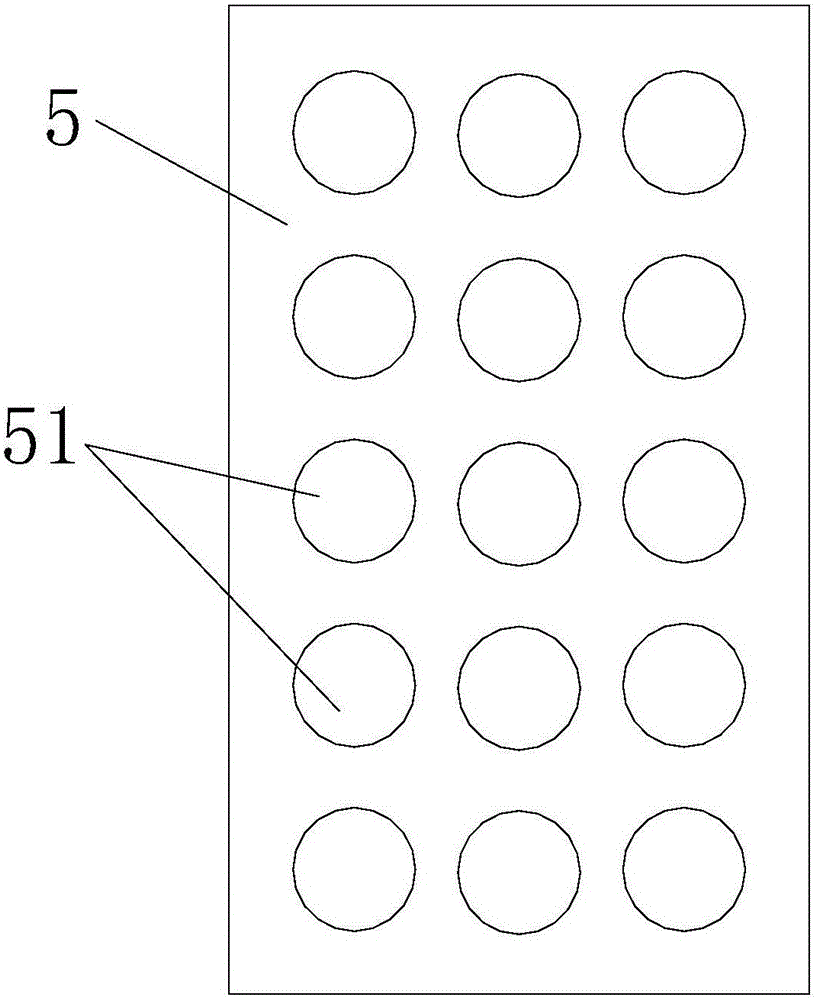

[0022] Such as Figure 1-2 As shown, the present embodiment provides a device for avoiding rudder turning and overturning, including a hull 1, a propeller 2 and a stern rudder 3 are arranged at the tail of the hull 1, and a liftable support frame 4 is arranged at the tail of the hull 1, Both ends of the support frame 4 are respectively connected with control baffles 5, and the free ends of the control baffles 5 are respectively connected to both sides of the hull 1 through drag cables 6. The control baffles 5 are provided with a number of openings. The combined control hole 51, when making a sharp turn with full rudder, the control baffle 5 can effectively unload part of the thrust of the stern rudder 3, which is more conducive to controlling the attitude of the ship, and completely solves the problem that the ship is prone to capsize during full rudder steering. The problem greatly improves the safety of the ship test and navigation process.

[0023] Wherein, the stern of th...

Embodiment 2

[0027] This embodiment provides a method for applying the device for avoiding rudder turning and overturning, which is characterized in that:

[0028] S1. When the ship sails forward normally, the support frame 4 is on the upper part of the slide rail, and the control baffle 5 is placed on the deck of the hull 1;

[0029] S2. When it is necessary to use the control baffle 5 to unload the thrust of the stern rudder 3 during the steering process of the hull 1, the support frame 4 is lowered along the slide rail, and the two control baffles 5 are respectively located on the left and right sides of the stern rudder 3 , the control hole 51 on the control baffle 5 is in an open state;

[0030] S3, when the stern rudder 3 is biased to the left, the control hole 51 on the control baffle plate 5 on the right side of the stern rudder 3 is closed, and part of the thrust of the stern rudder 3 is unloaded;

[0031] S4, when the stern rudder 3 is biased to the right, the control hole 51 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com