Anode and cathode device of on-site metallographic electrolytic polishing corrosion instrument and using method thereof

An electrolytic polishing, on-site gold technology, applied in the electrolytic process, electrolytic components, etc., can solve the problems of the cathode-anode device unable to metallographic test, unable to meet the needs of metallographic test and failure analysis, etc., to achieve effective and rapid installation, connection and removal. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

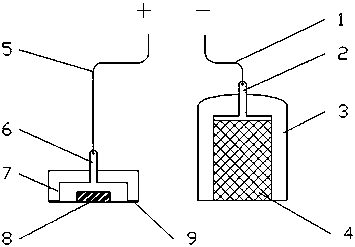

[0023] The following combination figure 1 , a preferred embodiment of the present invention is described in detail.

[0024] Such as figure 1 As shown, the anode and cathode device of the on-site metallographic electrolytic polishing and corrosion instrument provided by the present invention includes: a power supply; The points are separated by a certain distance. In order to ensure a certain range of current, the distance is about 5cm; the cathode assembly is connected to the negative pole of the power supply through a circuit, and after absorbing the chemical polishing reagent, it is connected to the metallographic inspection site on the large workpiece. Contact, after turning on the power, electrolytic polishing and corrosion are performed on the metallographic inspection points.

[0025] The cathode assembly includes: a cathode casing 3; a cathode body 2, which is arranged in the cathode casing 3, and one end of the cathode body 2 protrudes from the cathode casing 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com