Implementation method and construction process of suspension type monorail transportation rigid-frame system

A technology of monorail transportation and construction technology, which is applied in the direction of tracks, roads, buildings, etc., and can solve problems such as track beam deformation, small span of track beams, and unfavorable earthquake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in conjunction with examples.

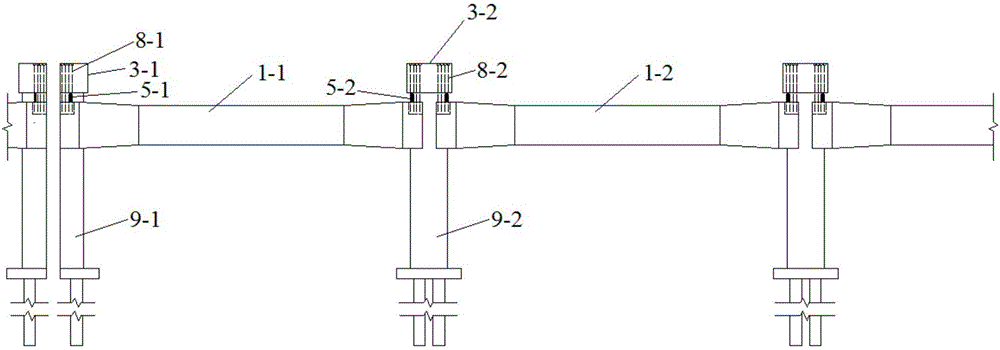

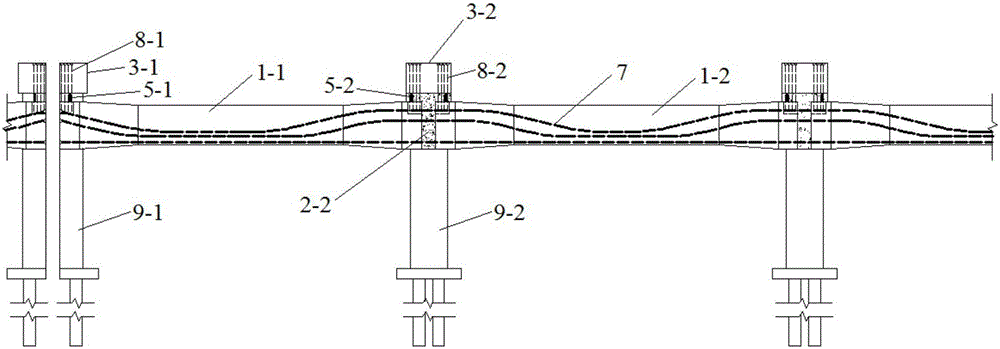

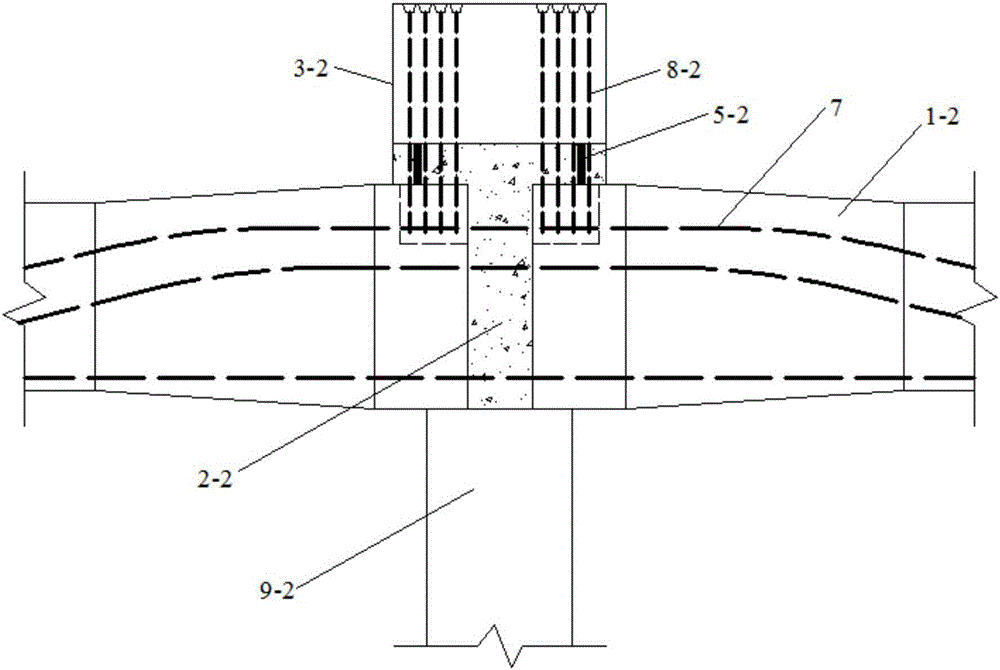

[0025] Realization Method of Suspension Monorail Transit Rigid Frame System

[0026] In the realization of a suspended monorail concrete structure rigid frame system, the concrete track beam 1-1, the concrete track beam 1-2, the wet joint 2-1, the wet joint 2-2, and the concrete cover beam 3- 1. Concrete cover beam 3-2, running surface joint plate 4-1, guide surface joint plate 4-2, vertical adjustment device 5-1, vertical adjustment device 5-2, second-stage prestressed tendons 7, Drag cable 8-1, drag cable 8-2, pier 9-1, pier 9-2, leading screw jack 10-1, leading screw jack 10-2.

[0027] Step 1 Prefabricate the concrete track beam 1-1 and concrete track beam 1-2 used in the rigid frame system in the workshop, and transport them to the erection site.

[0028] Step 2 Concrete pier 9-1 and pier 9-2, set vertical adjustment device 5-1 at the design position of the bottom surface of concrete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com