Pressure-adjustable and capacity-adjustable hydraulic energy recycling and storing system and working method of hydraulic energy recycling and storing system

A storage system and hydraulic energy technology, which is applied to earth movers/excavators, construction, etc., can solve the problems of loss, energy loss, frequent elongation and recovery of hydraulic cylinders, etc., so as to reduce the cost of construction and use without sacrificing Vehicle performance, effect of improving recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

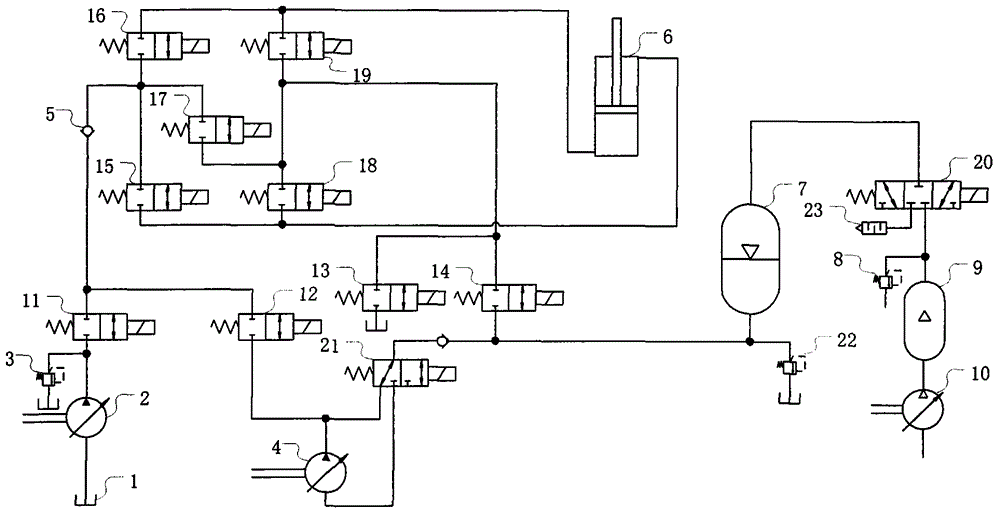

[0025] For the technical means that the present invention realizes, the purpose of the invention and the technical effect are easy to understand, below in conjunction with appendix figure 1 The present invention is described in further detail:

[0026] figure 1 Among them, the hydraulic energy recovery and storage system with adjustable pressure and capacity of the present invention includes: oil cylinder 1, variable hydraulic pump 2, hydraulic switch network, hydraulic cylinder 6, hydraulic accumulator 7, pneumatic accumulator 9, three-position three One-way valve 20 and two-position three-way valve 21. Wherein, the variable hydraulic pump 2 is connected to the oil cylinder 1, and the output end is connected to the hydraulic switch network. The hydraulic switch network communicates with the hydraulic accumulator 7 . The hydraulic accumulator 7 is an air-filled hydraulic tank with a lower hydraulic chamber and an upper compressed air chamber. The compressed air chamber of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com