Simple quick lifting drill collar

A drill collar and simple technology, applied in drill pipe, drill pipe, drilling equipment and other directions, can solve problems such as hidden safety hazards, low efficiency, and lack of in-depth research on slope angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further explain the technical means and functions adopted by the present invention to achieve the intended invention purpose, the structure, features and functions of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

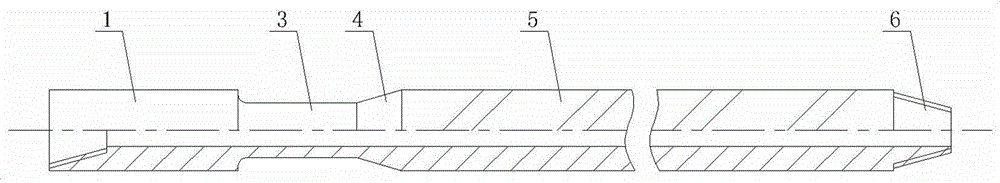

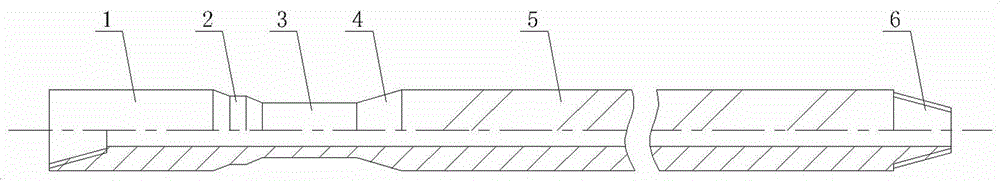

[0024] (1) Product structure

[0025] The drill collar described in the present invention has a structure such as figure 2 As shown, there are upper joint section 1, elevator groove 3, cone section 4, and drill collar body 5. The boundary between upper joint section 1 and elevator groove 3 is connected by stage 2 transition, and stage 2 includes at least one cylinder segment and two cone segments, according to actual needs, a cylinder segment and a cone segment can also be added, for example designed as two cylinder segments and three cone segments.

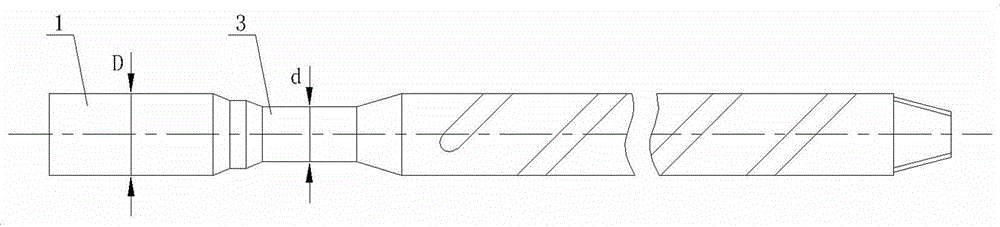

[0026] For different outer diameters (ie image 3 The drill collar in D) adopts the same size elevator groove 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com