Coordinate measuring machine, probing system and method for compensating force at probe element

A technology of coordinate measuring machine and detection system, which is applied in the force field of coordinate measuring machine, detection system and compensating probe elements, to avoid cross-coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

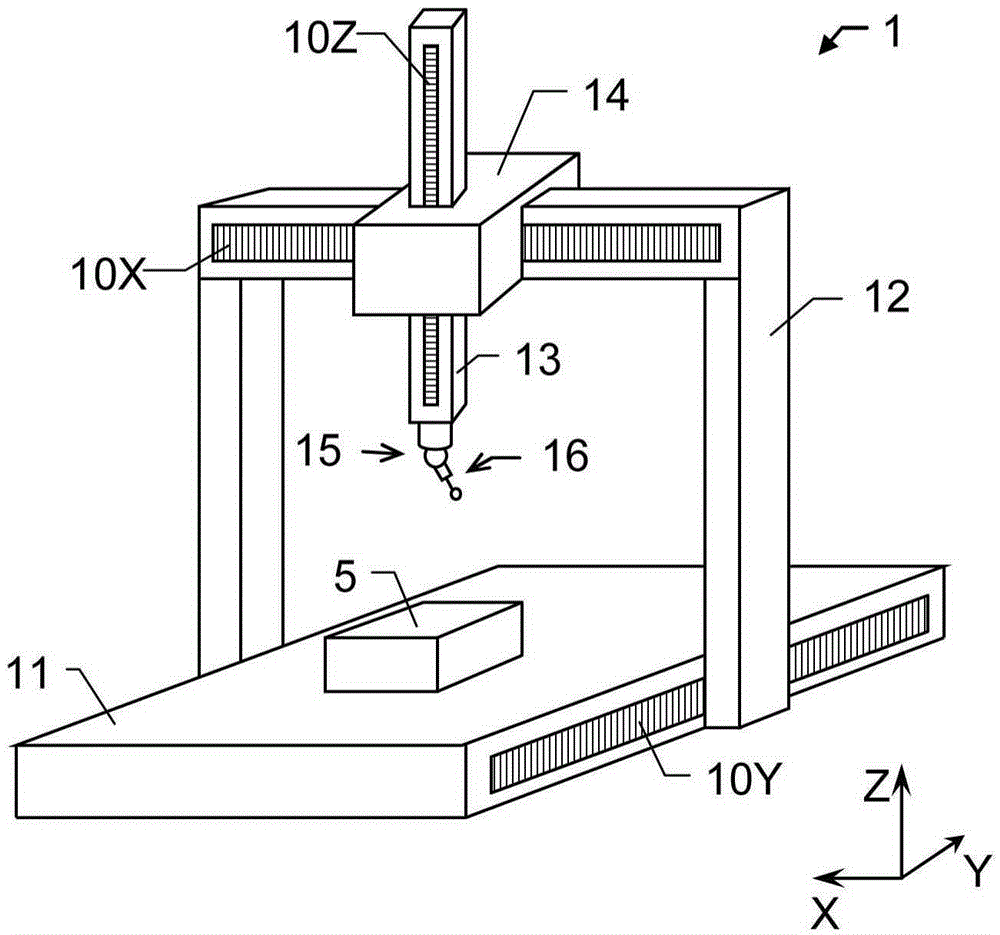

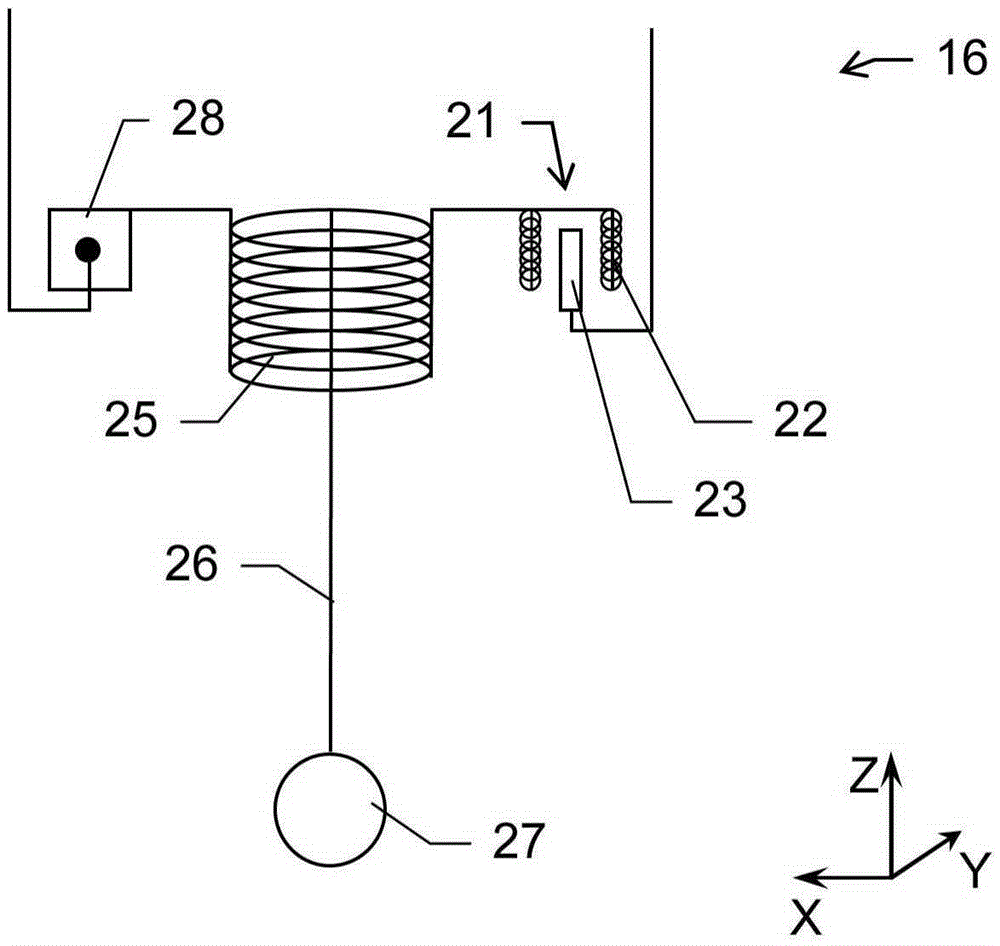

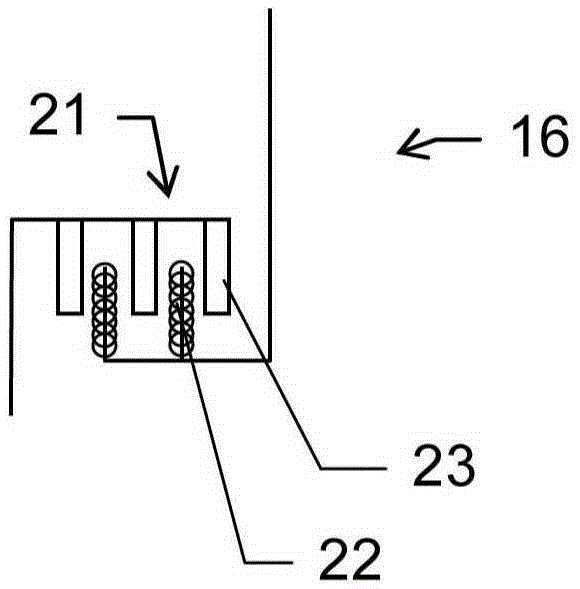

[0112] exist figure 1 In, an exemplary embodiment of a gantry coordinate measuring machine 1 (CMM) according to the present invention is depicted, the coordinate measuring machine 1 comprising a base 11 and a frame structure for connecting a probe 15 and a device connected to the probe 15. The detection unit 16 is coupled to the base 11, said frame structure comprising several frame parts 12, 13, 14 movable relative to each other. The first frame part 12 is a mast having two mast legs connected by a bridge portion at their upper ends. Driven by a drive mechanism (not shown), the frame part 12 is movable along the longitudinal edge of the base 11 . This direction corresponds to the first direction Y. The movement of the frame part 12 is in particular via a toothed rack attached to the base 11 , which meshes with a gear on the frame part 12 .

[0113] Brackets 14 are movably arranged on bridge portions 12 between the frames. The movement of the carriage 14 (the carriage 14 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com