Chuck-type wing loading device

A loading device and chuck-type technology, which is applied in the field of chuck-type wing loading devices, can solve problems such as damage, inaccurate equipment weight deduction, and excessive clamping load applied to the wing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present invention will be further described in detail below.

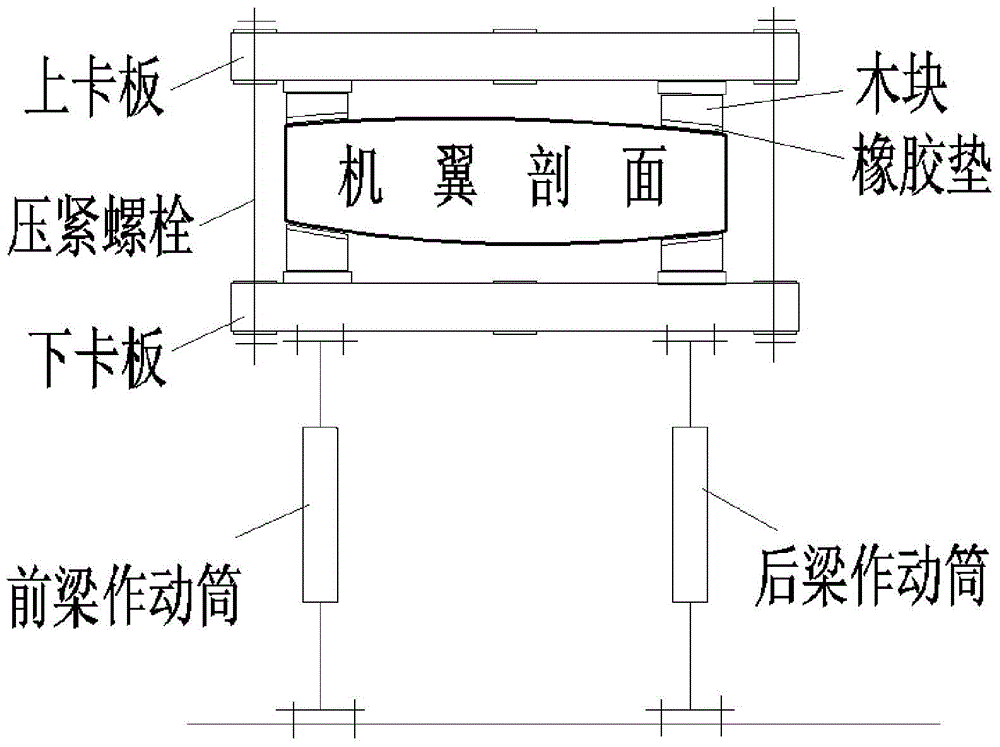

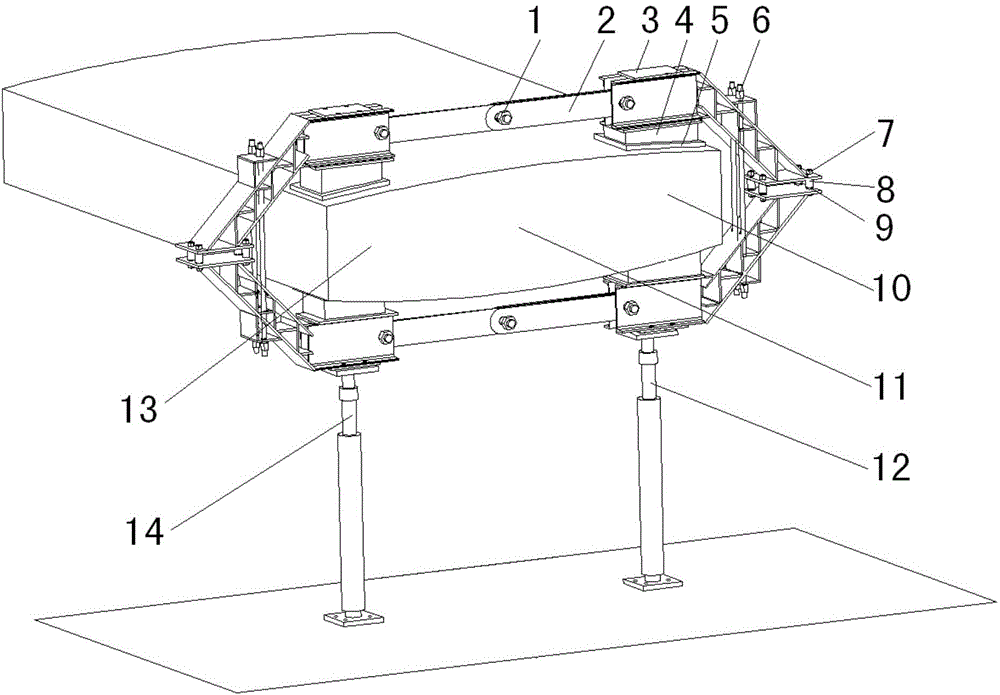

[0030] see figure 2 , the chuck type wing loading device of the present invention comprises a pull plate bolt 1, a pull plate 2, a loading chuck 3, a loading block 4, a square rubber pad 5, a chuck pressing bolt 6, a chuck connecting bolt 7, a bushing 8. Spring washer 9, rear beam 10, wing section 11, rear beam actuator 12, front beam 13 and front beam actuator 14.

[0031] Wherein, the tie plate bolts are standard parts, the material is usually 45 steel, and the quantity is 6 pieces, such as image 3 As shown, it is used to connect the pull plate to the pull plate, and also to connect the pull plate to the loading chuck.

[0032] Labanru Figure 4 As shown, it is processed by steel plate, the material is usually Q235 steel, the quantity is 6 pieces, and it is used to connect the loading chuck at the position of the front and rear beams.

[0033] Load the chuck as Figure 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com