Composite resonance sound absorption structure

A resonant sound-absorbing and sound-absorbing technology, which is applied in the direction of sound-emitting devices, instruments, and layered products, can solve problems such as the inability to realize the processing of micro-perforated plates with ultra-micro-pore diameters, unsuitable for mass production, and poor sound-absorbing effects. Achieve the effect of good sound absorption effect, low price and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

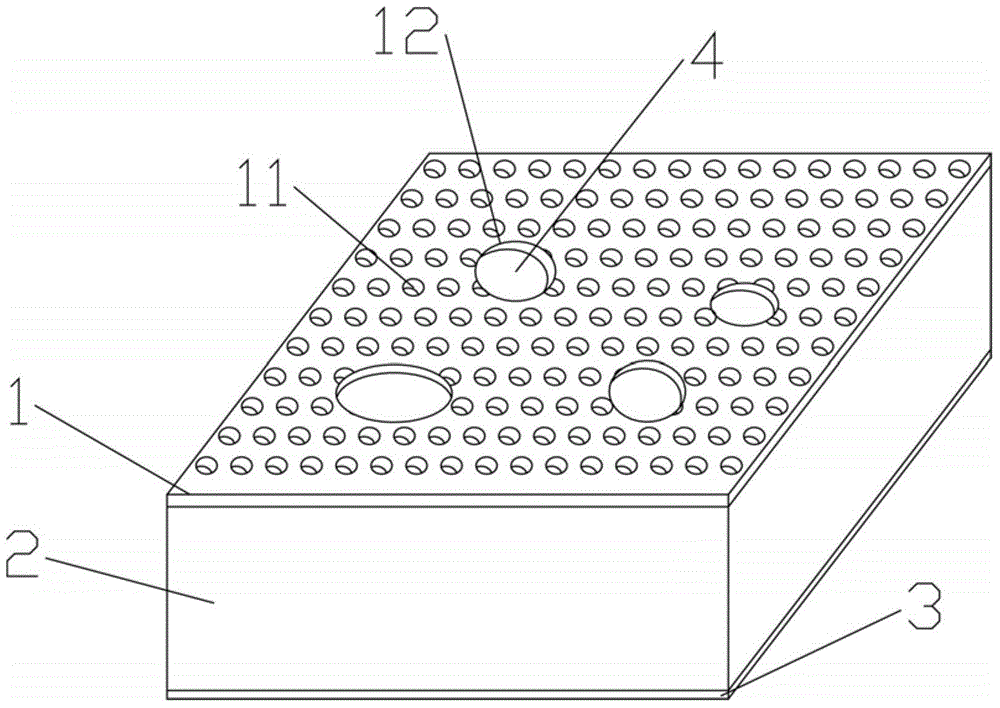

[0024] refer to figure 1 As shown, the composite resonance sound-absorbing structure includes: a bottom plate 3, a side wall 2 and a cover plate 1, the cover plate 1 and the bottom plate 3 are relatively spaced apart, and the side walls 2 are closely connected with the bottom plate 3 and the cover plate 1 respectively to form a sound-absorbing back cavity. The depth of the sound-absorbing back cavity is 5-80mm, preferably 5mm, 10mm, 15mm, 20mm, 50mm or 80mm. The cross section of the side wall 2 is a closed structure, preferably in the shape of "O", "mouth" or "Tian". refer to figure 1 As shown, the bottom plate 3 and the cover plate 1 are arranged in parallel, the side wall 2 is perpendicular to the bottom plate 3 and the cover plate 1, and the two ends of the side wall 2 are closely connected with the bottom plate 3 and the cover plate respectively, forming one or more sound-absorbing back cavity. The cover plate 1 is provided with a plurality of micro sound absorption ho...

Embodiment 2

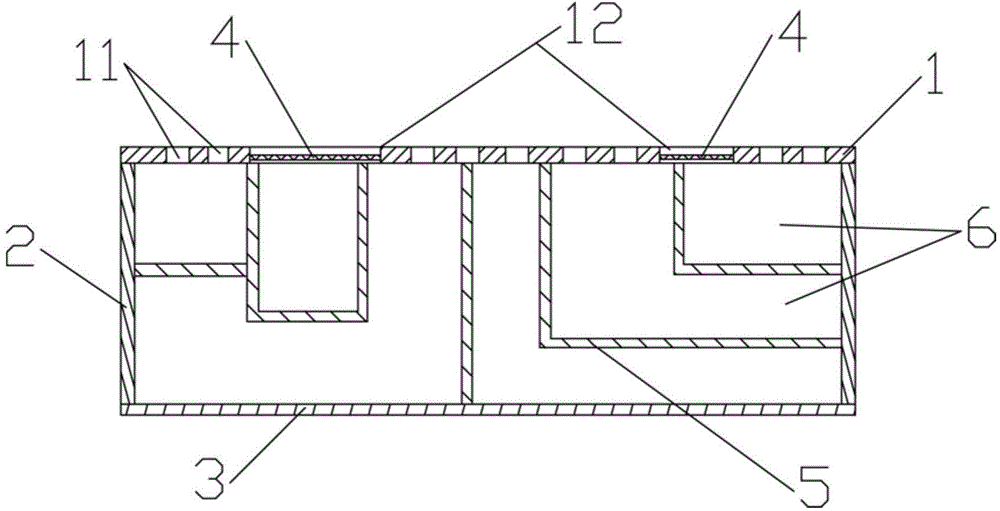

[0032] This embodiment is basically the same as Embodiment 1, the difference is: refer to image 3 As shown, the composite resonance sound-absorbing structure also includes a partition plate 5; the partition plate 5 is closely attached to the inner wall of the cover plate 1, the bottom plate 3 and / or the side wall 2, and divides the sound-absorbing back cavity into a plurality of independent absorbing Acoustic chambers 6 ; each sound-absorbing chamber 6 communicates with micro-sound-absorbing holes 11 and / or composite sound-absorbing holes 12 . The partition plate 5 divides the sound-absorbing back cavity into multiple sound-absorbing chambers 6, and the depths of the multiple sound-absorbing chambers 6 are not exactly the same. vertical height. The number of partitions 5 is multiple, and the shapes of the partitions 5 can be various, so that the sound absorption chamber 6 is a cuboid, cylinder, cone or irregular body and the like. Sound waves flow into the sound-absorbing c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com