T-shaped tube entrainment test system and method based on fourth-level depressurization system of reactor

A test system and reactor technology, applied in the field of steam-water two-phase flow thermal-hydraulic test research, can solve problems such as inability to conduct visual research, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

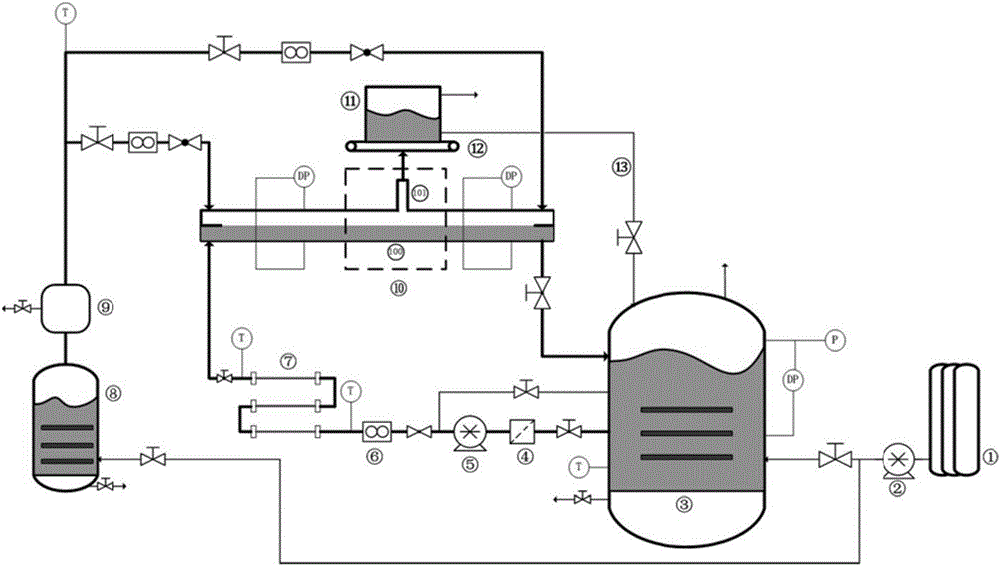

[0032] see figure 1 , a T-tube entrainment test system based on the reactor's fourth-stage decompression system of the present invention, comprising: a deionized water preparation system 1, a replenishment pump 2, a heating water tank 3, a filter 4, a high-temperature pump 5, a mass flow meter 6, Preheating section 7, boiler 8, cylinder 9, visualization test section 10, weighing water tank 11, weighing sensor 12 and return water pipeline 13.

[0033] The deionized water preparation system 1 is connected to the heating water tank 3 through the supplementary water pump 2. After being heated by the heating water tank 3, the liquid phase enters the preheating section 7 through the filter 4 and the high temperature pump 5, and then is sent to the test section 10; The water flowing out of the water preparation system 1 flows into the boiler 8 through a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com