Aligning apparatus for image module and application method thereof

An image module and core-alignment technology, which is applied in image communication, television, electrical components, etc., can solve problems such as the alignment of the lens module and the photosensitive chip, the inability of the image module to produce a clear image, vibration and dust interference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] According to the claims of the present invention and the content disclosed in the specification, the technical solution of the present invention is specifically described as follows.

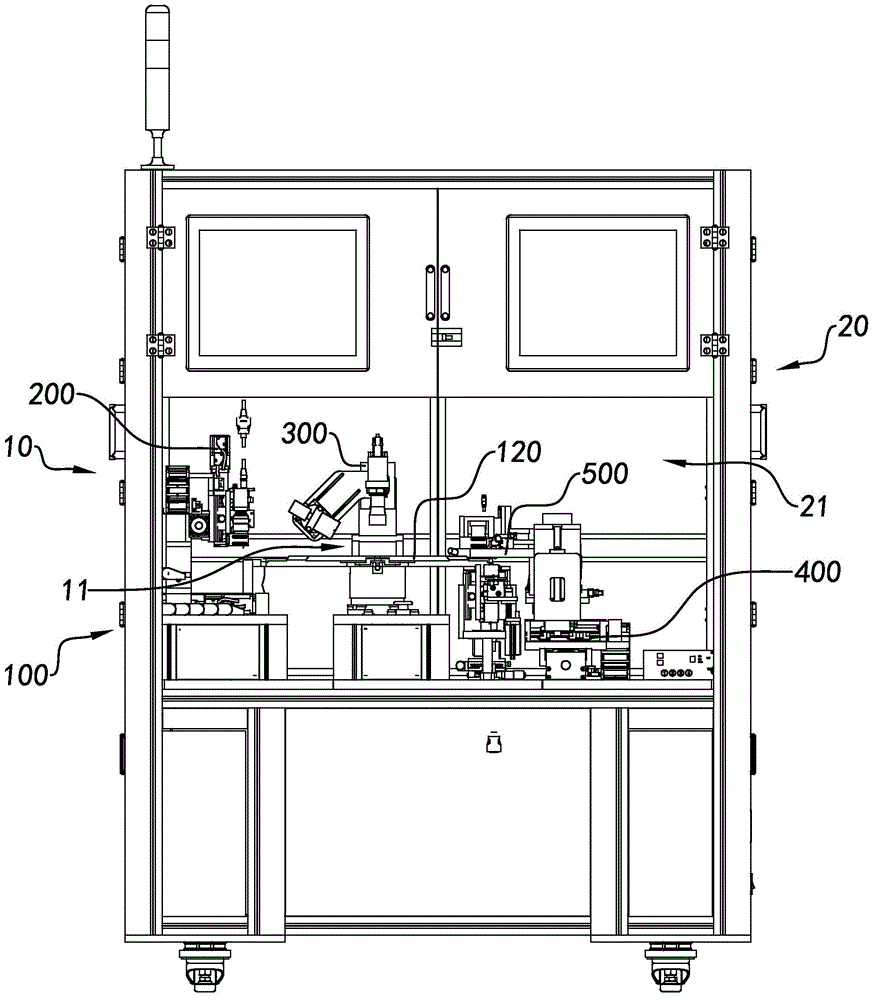

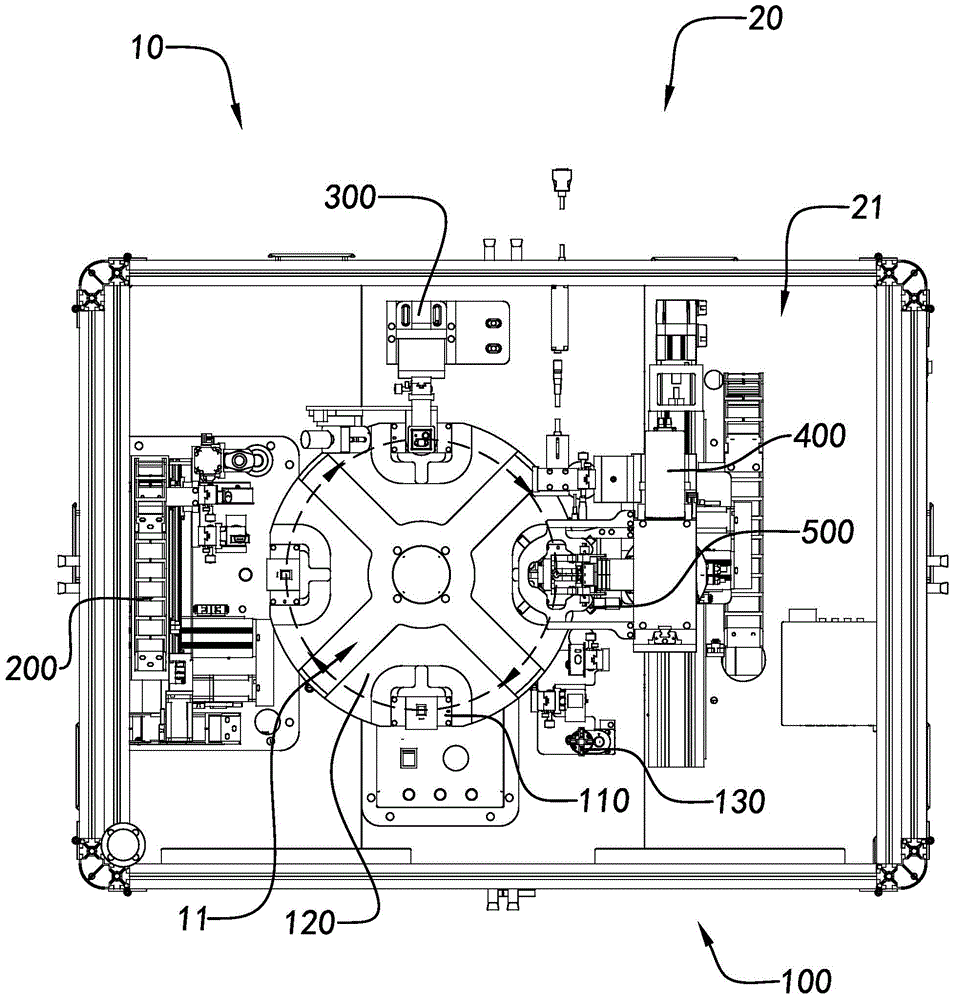

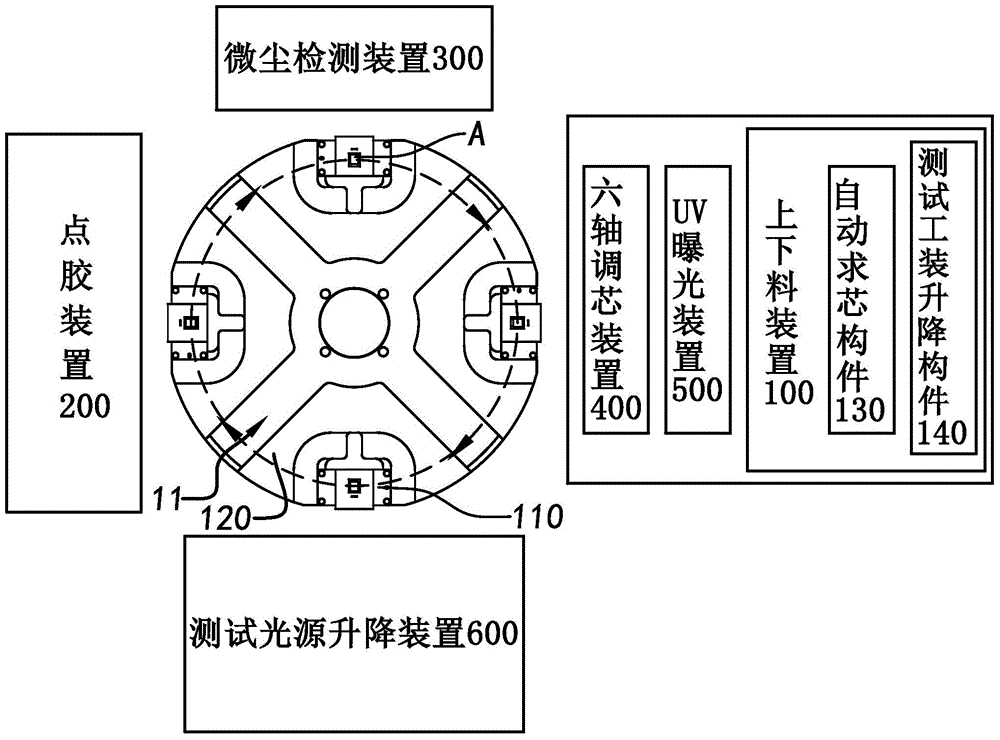

[0069] Such as Figure 1 to Figure 4 Shown is a centering device for an image module A, which includes a plurality of operable devices 10 selectively acting on the image module A to rotate the image module A from one device to another A kind of device, to implement different operation applications on it, realize the online integrated alignment process of the image module A, greatly improve the alignment accuracy and the alignment efficiency of the product, which is conducive to the development of alignment in the automatic mode, reducing The positional accuracy deviation of the image module A in the centering process.

[0070] The centering equipment of the image module A further includes an equipment frame part 20, and the equipment frame part 20 is used for respectively connecting the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com