A kind of hot-melt hook degradable PLA hook and loop fastener and manufacturing method thereof

A manufacturing method and technology of Velcro, applied in fasteners, clothing, pretreated surfaces, etc., can solve the problems of non-biodegradability, environmental pollution, obvious thorn feeling, etc., and achieve the effect of optimizing the weaving process and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

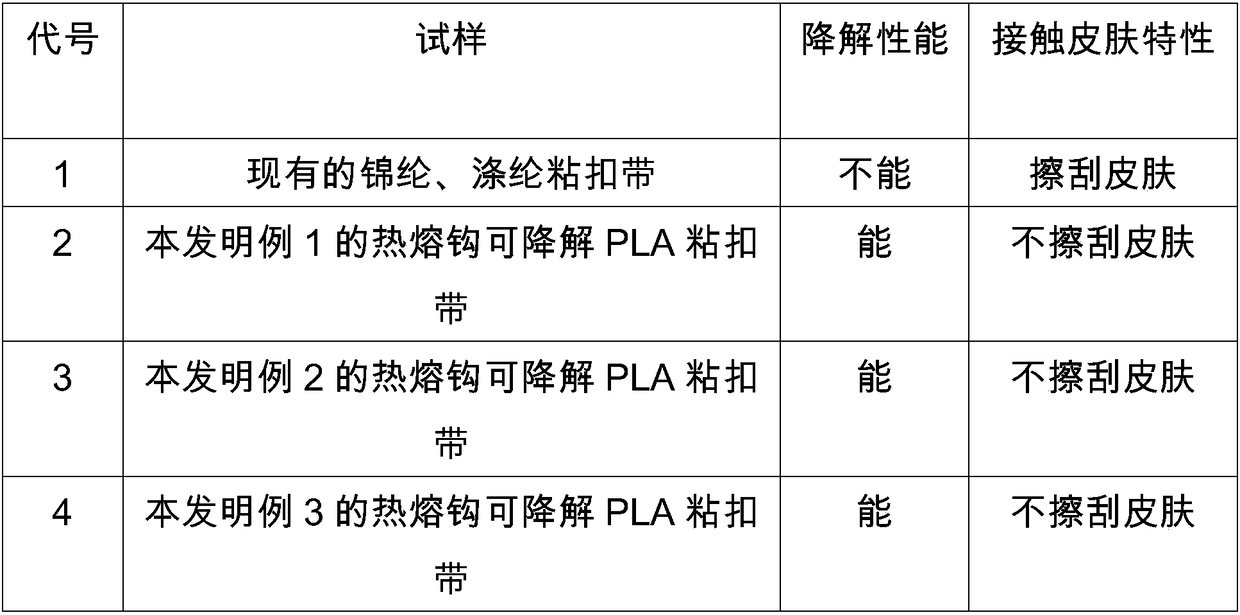

Embodiment 1

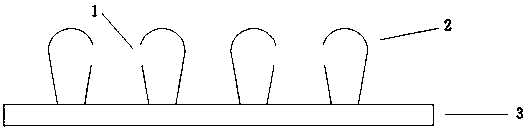

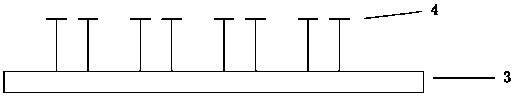

[0028] Step 1: Reasonably design the structural parameters of the hook and loop fastener. The arrangement of the warp yarns in the fabric is as follows: 1 hook warp polylactic acid monofilament: 6 ground warp polylactic acid multifilaments, that is, the weft hook density is: 1 hook / 6 hooks Ground warp; the hook density in the warp direction is 1 hook / 5 weft yarns. If the hook density is too large, different adjacent hooks are easily bonded together during hot melting, forming melting defects. The hook density is too small, and the hooking strength of the hook and loop is low ; The density of the warp and weft yarns in the fabric structure is: the diameter of the polylactic acid monofilament in the hook warp is 0.14mm, and the ground warp and weft yarns are 14tex / 70f.

[0029] Step 2: Optimize the weaving process, and the height of the weaving hook loop is 1.8mm.

[0030] Step 3: Apply water-based PU glue to the bottom layer of the hook and loop and dry it, so that the texture ...

Embodiment 2

[0033] Step 1: Reasonably design the structural parameters of the hook and loop fastener. The arrangement of the warp yarns in the fabric is as follows: 1 hook warp polylactic acid monofilament: 7 ground warp polylactic acid multifilaments, that is, the weft hook density is: 1 hook / 6 hooks Ground warp; the hook density in the warp direction is 1 hook / 4 weft yarns. If the hook density is too large, different adjacent hooks are easy to bond together when hot-melted, forming melting defects. The hook density is too small, and the hook strength of the hook and loop is low. ; The density of the warp and weft yarns in the fabric structure is: the diameter of the polylactic acid monofilament in the hook warp is 0.15mm, and the ground warp and weft yarns are 16tex / 80f.

[0034] Step 2: Optimizing the weaving process, the height of the weaving hook loop is 2.0mm.

[0035] Step 3: Apply water-based PU glue to the bottom layer of the hook and loop and dry it, so that the texture of the h...

Embodiment 3

[0038]Step 1: Reasonably design the structural parameters of the hook and loop fastener. The arrangement of the warp yarns in the fabric is as follows: 1 hook warp polylactic acid monofilament: 7 ground warp polylactic acid multifilaments, that is, the weft hook density is: 1 hook / 6 hooks Ground warp; the hook density in the warp direction is 1 hook / 5 weft yarns. If the hook density is too large, different adjacent hooks are easily bonded together during hot melting, forming melting defects. The hook density is too small, and the hooking strength of the hook and loop is low ; The density of the warp and weft yarns in the fabric structure is: the diameter of the polylactic acid monofilament in the hook warp is 0.16mm, and the ground warp and weft yarns are 18tex / 90f.

[0039] Step 2: Optimizing the weaving process, the height of the weaving hook loop is 1.8-2.2mm.

[0040] Step 3: Apply water-based PU glue to the bottom layer of the hook and loop and dry it, so that the texture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com