Water purifier capable of automatically cleaning ceramic filter element

A technology of ceramic filter elements and water purifiers, which is applied to fixed filter element filters, filtration separation, membrane filters, etc., and can solve the problems of filter element loss and troublesome operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A detailed description will be given below of specific embodiments of the present invention according to the accompanying drawings.

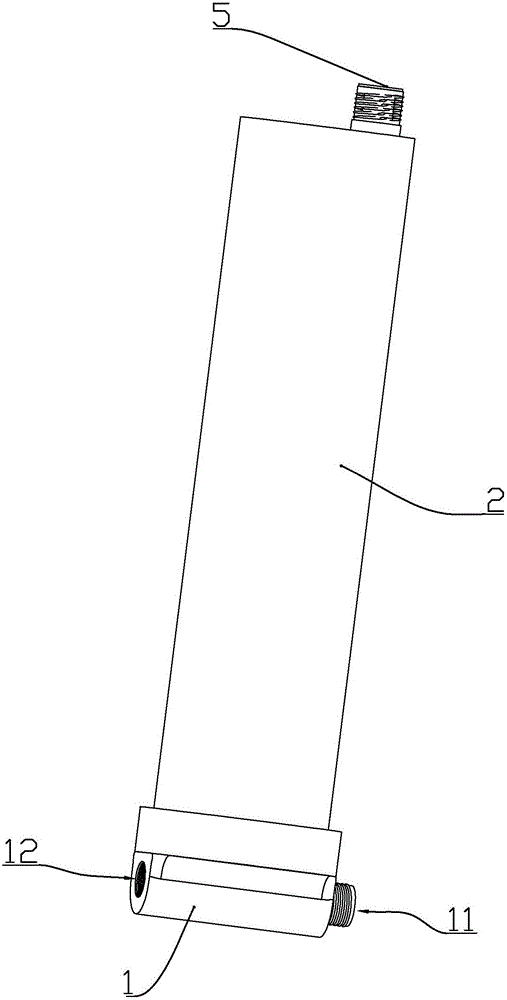

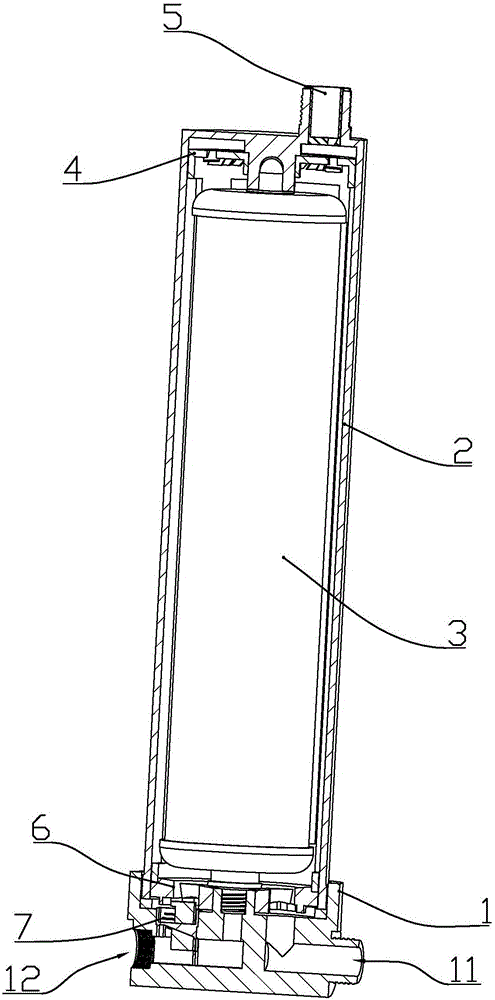

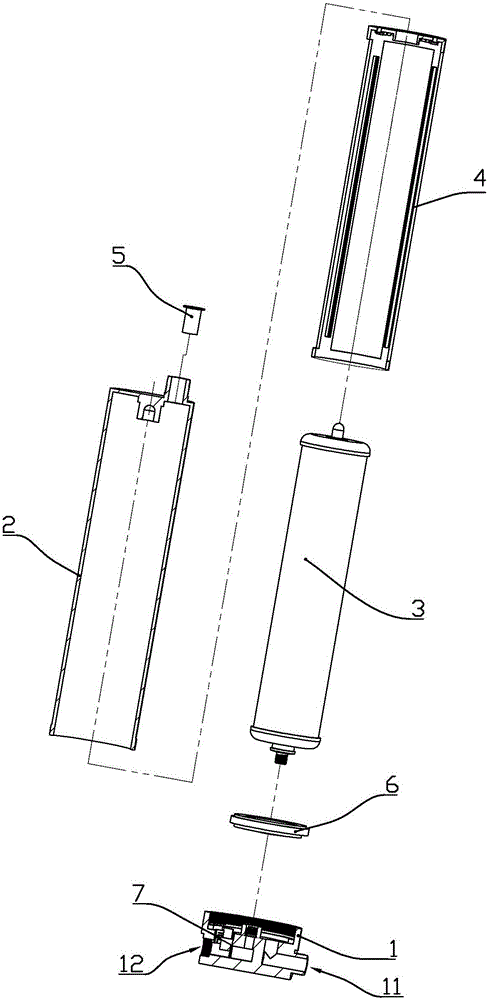

[0056] according to Figure 1 to Figure 11 As shown, a self-cleaning ceramic filter element water purifier described in this embodiment includes a cylinder body 2 and a cover body 1 connected by threads, and a ceramic filter element assembly 3 installed in the space between the cylinder body and the cover body .

[0057] Both sides of the cover body are respectively formed with a non-drinking water outlet interface 11 and a drinking water outlet interface 12; a drinking water outlet joint 14 is integrally formed in the middle of the inner bottom of the cover body, and the drinking water outlet joint is connected to the drinking water outlet joint. The water outlet interface is connected; the inner bottom of the cover body is also formed with a non-drinking water outlet 111 connected with the non-drinking water outlet interface, and a sea...

Embodiment 2

[0078] combine Figure 1 to Figure 12 As shown, the present embodiment is a kind of energy-saving water supply system, including the ceramic filter element water purification equipment P described in embodiment 1 or 2, and the tap water pipe 8 connected to the water inlet joint on the ceramic filter element water purification equipment, through drinking The water pipe 82 is connected to the drinking water faucet M connected to the drinking water outlet 12 , and the non-drinking water faucet N is connected to the non-drinking water outlet 11 through the non-drinking water pipe 81 (providing washing water). Said water pipe can be equipped with a main valve for controlling the whole water supply system near the ceramic filter core water purification equipment.

[0079] When the drinking water faucet is in the open state, the filtered water pushes the first magnet to move toward the second magnet, and the third magnet is attracted to the first magnet, so it also moves toward the s...

Embodiment 3

[0083] combine Figure 1 to Figure 11 ,as well as Figure 13 As shown, the present embodiment is an energy-saving water supply system, including the ceramic filter element water purification device P described in Embodiment 1, and the tap water pipe 8 connected to the water inlet joint on the ceramic filter element water purification device, through the drinking water pipe 82 is the drinking water faucet M connected to the drinking water outlet interface 12, and the non-drinking water faucet N (providing washing water) is connected to the non-drinking water outlet interface 11 through the non-drinking water pipe 81.

[0084] A master valve for controlling the entire water supply system is installed on the water supply pipe near the ceramic filter element water purification equipment.

[0085] A water pump is also connected to the pipeline behind the main valve on the said running water pipe through a three-way pipe.

[0086] combine Figure 14 to Figure 25 As shown, the wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com