Ultrafiltration water purifier convenient for sewage discharging

A water purifier and sewage chamber technology, applied in ultrafiltration, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of installation trouble, unable to remove raw water in time, unable to understand the quality of raw water, etc. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

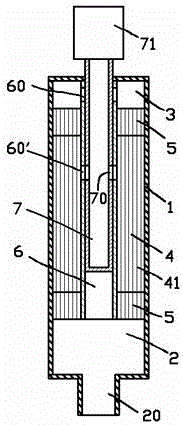

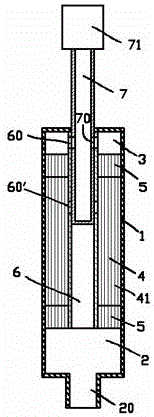

[0015] exist figure 1 , figure 2 In the shown embodiment one, the ultrafiltration water purifier that is convenient for sewage discharge includes a tubular shell 1, in which a water inlet chamber 2 and a sewage discharge chamber 3 are formed, and the water inlet chamber 2 Connected to the raw water inlet 20; a section of purification chamber 4 is separated by a sealing plug 5 between the water inlet chamber 2 and the sewage chamber 3; the purification chamber 4 is covered with ultrafiltration membrane cores 41, and the ultrafiltration membrane cores 41 run through The sealing plug 5 communicates with the water inlet chamber 2 and the sewage discharge chamber 3; a purification pipe 6 is also provided in the purification chamber 4, the lower end of the purification pipe 6 communicates with the water inlet chamber 2, and the upper end runs through the Described shell 1; Described purification pipe 6 is provided with a sliding plug pipe 7 that can slide along the purification pi...

Embodiment 2

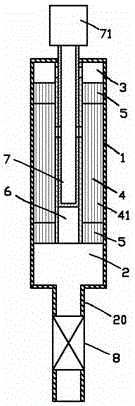

[0019] exist image 3 In the shown embodiment two, different from the first embodiment, a constant pressure valve 8 is connected in series in the raw water inlet 20 of the water inlet chamber 2, and the constant pressure valve makes the hydrostatic pressure in the water inlet chamber 2 greater than The maximum upward sliding resistance of the sliding plug tube 7 (that is, the upward sliding resistance when the sliding plug tube 7 is at the lower limit position), and the difference between the hydrostatic pressure and the upward sliding resistance is less than a set value. According to this scheme, when the water purifier works in a normal water purification state, since the water flow in the water inlet chamber 2 can pass through the ultrafiltration membrane core 41 and enter the slide tube 7 smoothly, the flow in the water inlet chamber 2 The water pressure is obviously lower than the upper sliding resistance of the sliding plug tube 7; and when the ultrafiltration membrane c...

Embodiment 3

[0021] exist Figure 4 In the third embodiment shown, different from the first embodiment, a buffer valve 9 is connected in series to the raw water inlet 20 of the water inlet chamber 2 , and a rubber air bag 91 is provided in the sewage discharge chamber 3 . According to the third embodiment, when the sliding plug pipe 7 is pulled up quickly, due to the buffering effect of the buffer valve 9, the raw water cannot be filled into the purification pipe 6 immediately, so that the rubber air bag 91 is contracted, so that The water body in the sewage chamber 3 enters the purification pipe 6 after passing through the ultrafiltration membrane core 41 and the water inlet chamber 2, so that the fouling in the ultrafiltration membrane core 41 can be washed downward strongly; After being pulled to the upper limit position, the water in the water inlet chamber 2 passes through the ultrafiltration membrane core 41, the sewage chamber 3, and enters the sliding plug pipe 7, thereby continuou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com