A vertical biomass pellet fuel molding machine

A technology of biomass granules and molding machines, which is applied in the direction of biofuel, waste fuel, mold extrusion granulation, etc. It can solve the problems of bearings being easily polluted by dust particles, equipment maintenance and maintenance time being long, and uneven wear of molds and pressure rollers. problems, to achieve the effect of compact structure, convenient gap adjustment, and reduced manufacturing and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

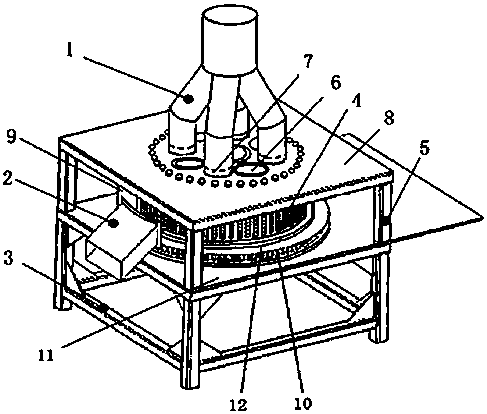

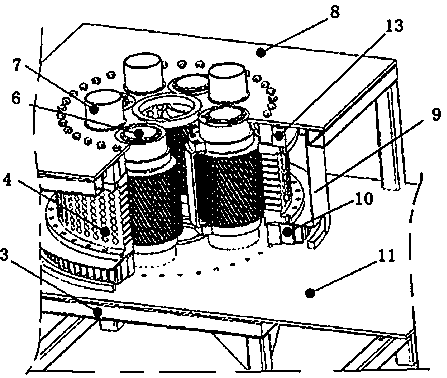

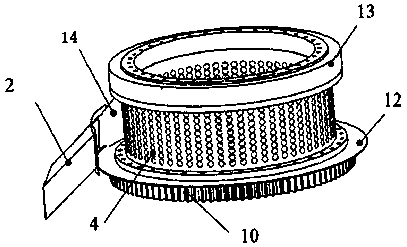

[0022] See figure 1 , 2 , the concrete structure is as follows: the present invention is provided with upper frame 5 and lower frame 3, and upper and lower ends of upper frame 5 are respectively fixed and assembled forming mold upper cover plate 8, forming mold lower cover plate 11; 8 and the lower cover plate 11 of the forming mold are provided with a compression cavity, and the compression cavity is composed of the upper cover plate 8 of the forming cavity, the upper support bearing 13, the ring die 4, the outer ring toothed bearing 10, the lower cover plate 11 of the forming mold, etc. A closed cavity formed by parts. The inner ring of the upper support bearing 13 and the upper cover plate 8 of the molding cavity are fastened and connected by bolts, and the outer ring of the upper support bearing 13 is also connected with the upper end surface of the ring die 4 by bolts; The ring gear end face of the ring toothed bearing 10 is connected, and the inner ring of the outer ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com