Gas-liquid two-phase flow uniform distributor with adjustable distribution ratio

A technology of gas-liquid two-phase flow and distribution ratio, applied in chemical instruments and methods, feeding devices, chemical/physical processes, etc., can solve the problem that the distribution ratio is difficult to keep constant, the distribution ratio cannot be adjusted, the theoretical distribution ratio is fixed, etc. problems, to achieve the effect of easy maintenance production, identical flow characteristics, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

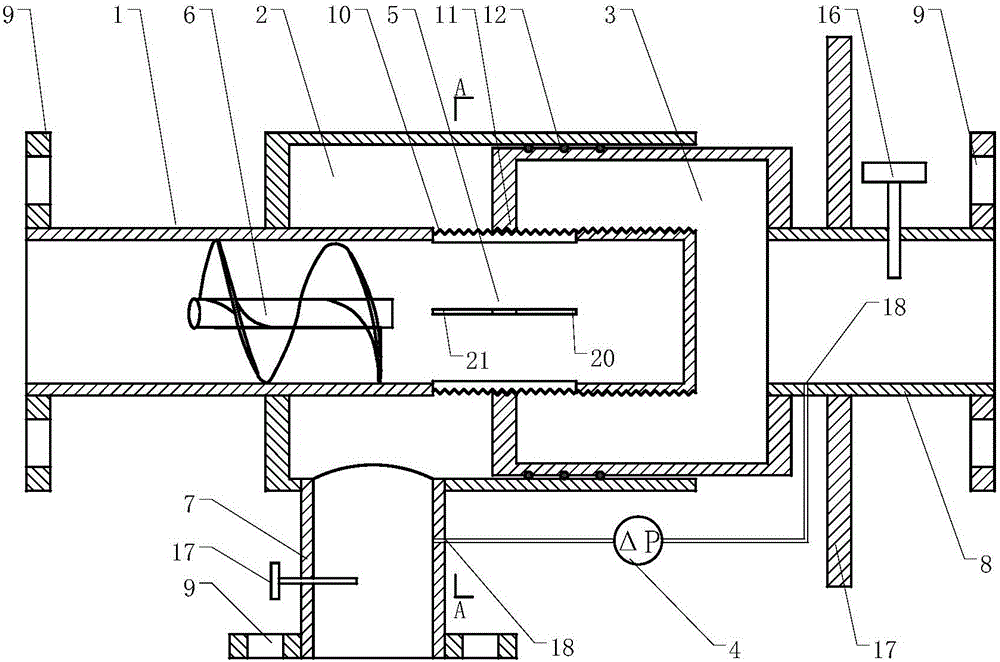

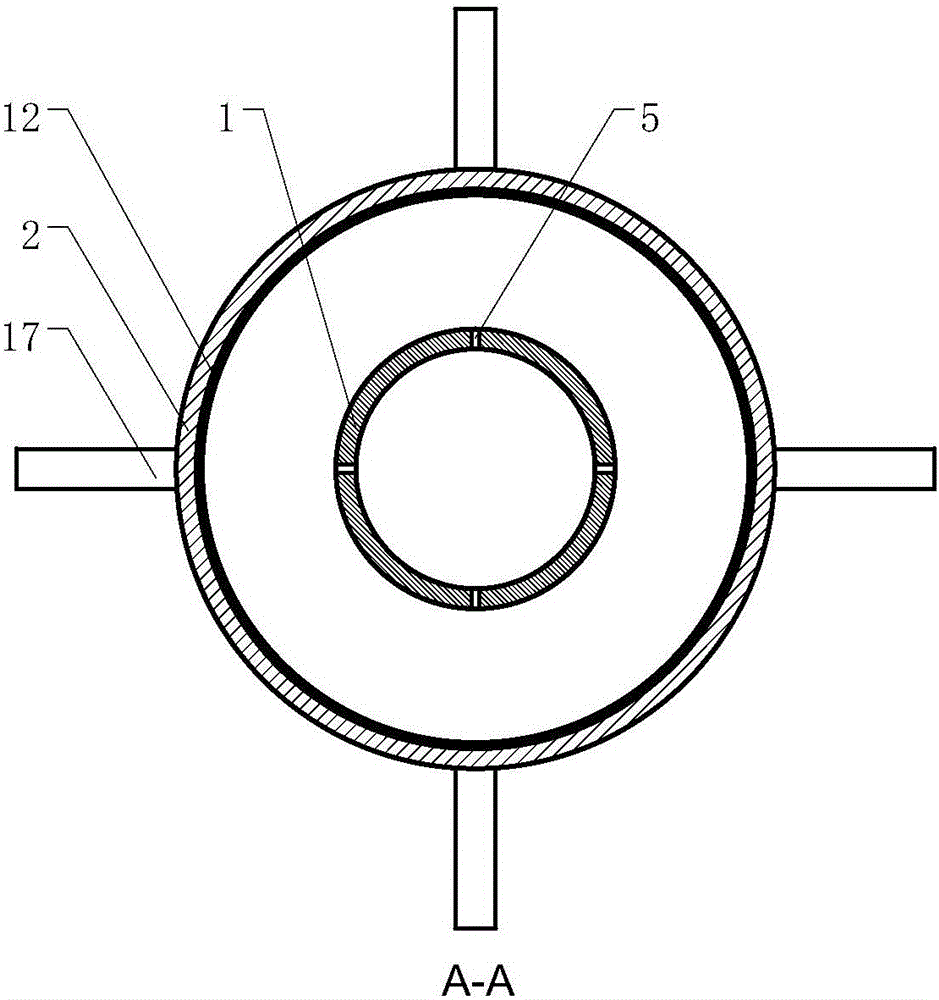

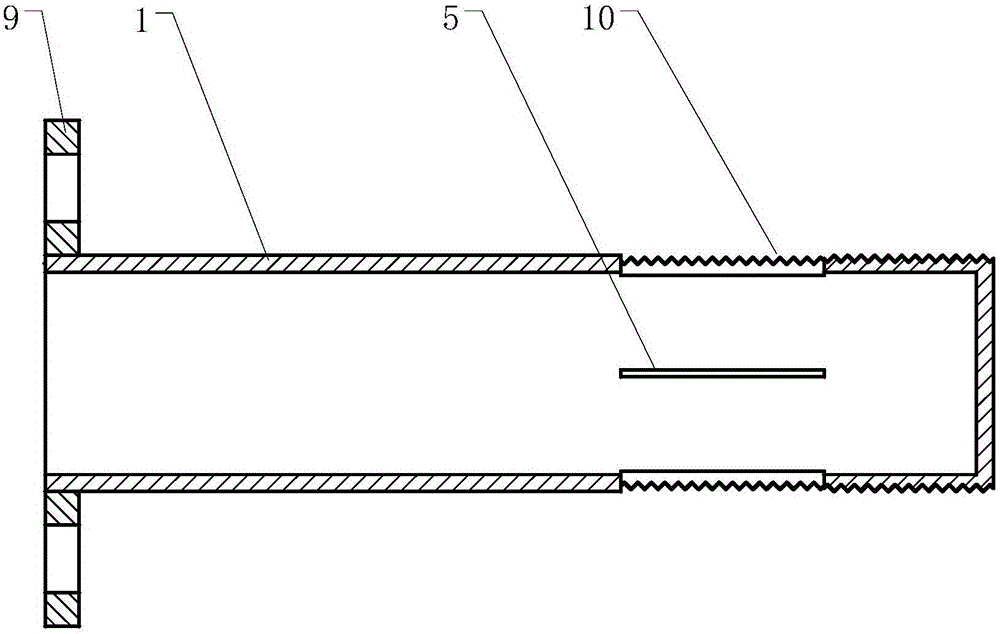

[0027] Such as figure 1 , figure 2 As shown, the present invention mainly includes a shunt pipe 1, a fixed distribution chamber 2, a rotating distribution chamber 3, and a differential pressure gauge 4. The shunt pipe 1, the fixed distribution chamber 2 and the rotating distribution chamber 3 are all cylindrical bodies, and all of the three remain the same. Shaft, the pipe wall of the distribution pipe 1 is arranged with several distribution grooves 5, the upstream of the distribution groove 5 is installed with a rectifier 6, the end of the distribution pipe 1 is closed, and the upper end surface of the fixed distribution chamber 2 is installed in the distribution groove 5 of the distribution pipe 1 On the upstream pipe wall, the lower end surface remains open, side branch pipe 7 is installed on the side wall surface of fixed distribution chamber 2, the upper end surface of rotating distribution chamber 3 is connected with shunt pipe 1 through threads, and the lower end surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com