Ship line of kilo-tonnage bulk carrier

A bulk carrier, thousand-ton technology, applied in the field of thousand-ton bulk carriers, can solve the problems of reduced ship economy, increased ship resistance, reduced speed, etc., to improve speed, save fuel, and reduce energy loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

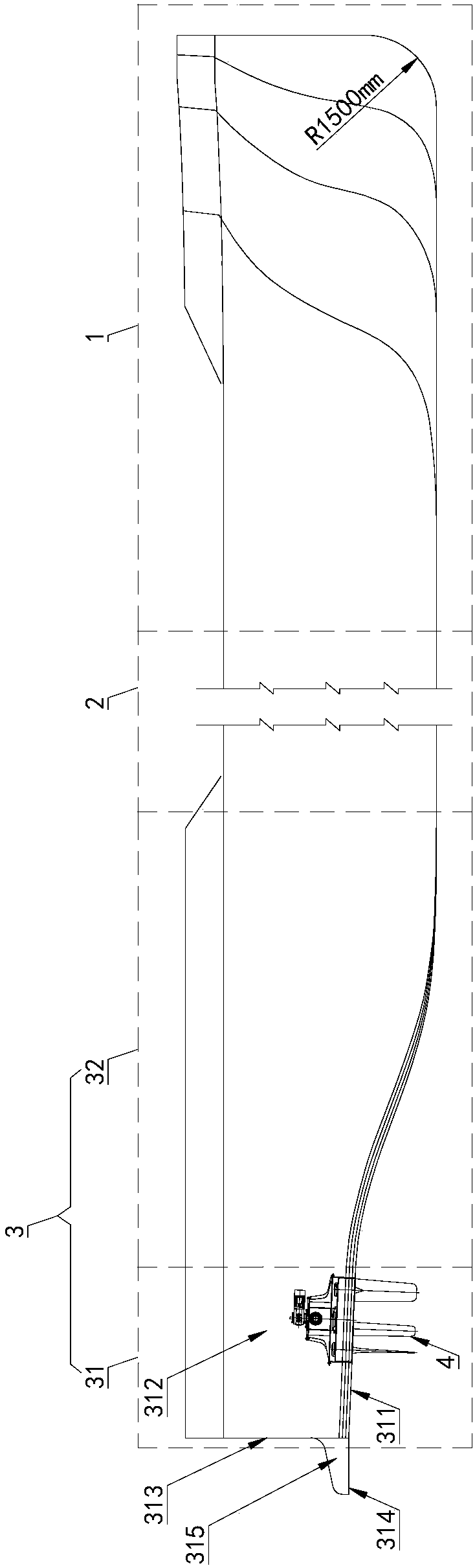

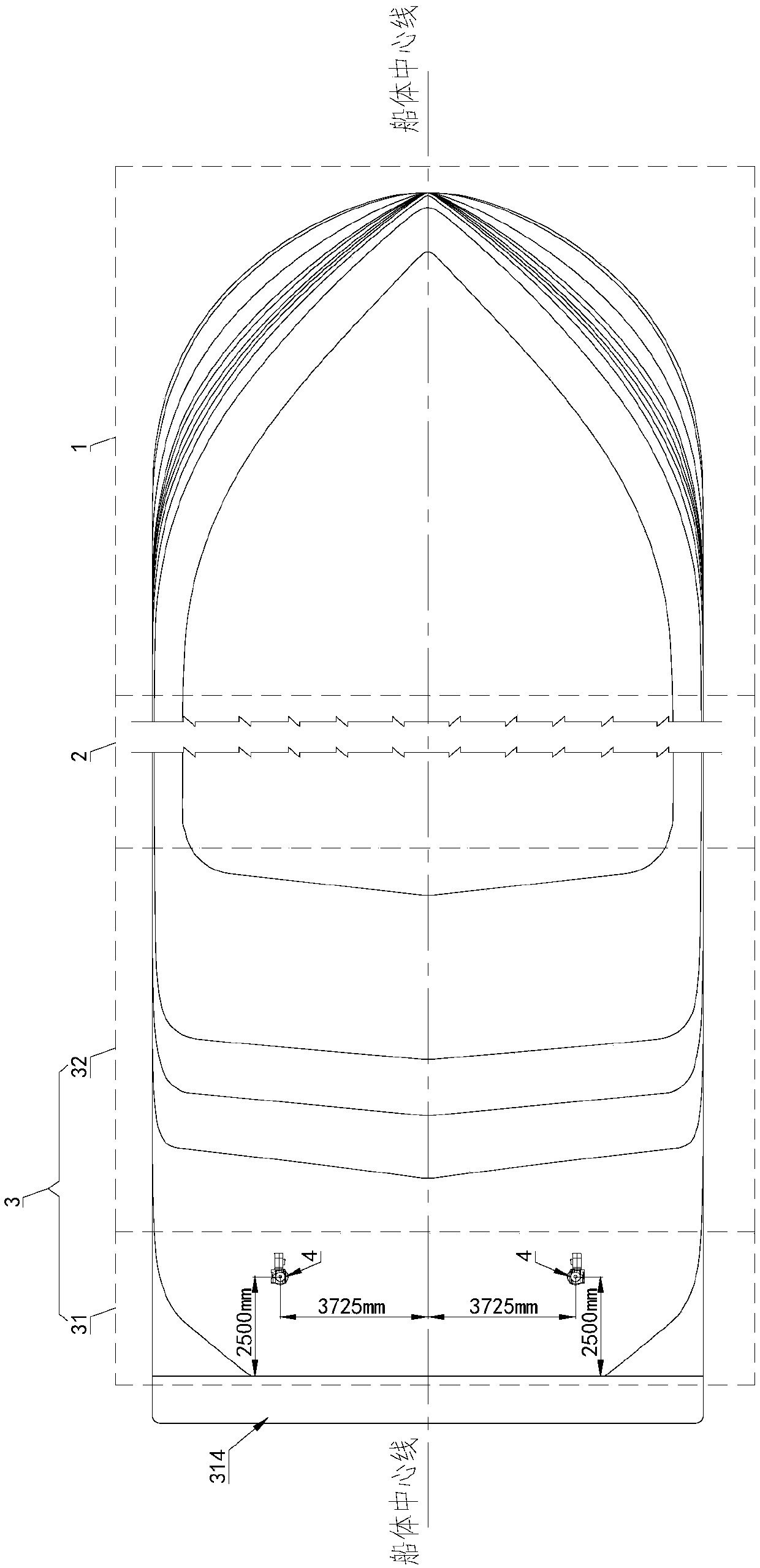

[0048] Such as figure 1 image 3 As shown, a thousand-ton bulk carrier ship type includes a hull bow 1, a hull middle 2, and a hull stern 3. It is characterized in that the hull bow 1 is a vertical bow, and its cross section is a floating side structure, and It is a middle U shape;

[0049] The middle part of the hull 2 is a parallel middle body, which is smoothly connected with the bow 1 of the hull;

[0050] The stern part 3 of the hull is a square stern, and the square stern includes a flow-out section 31 and a tail transition section 32, and the flow-out section 31, the tail transition section 32, and the parallel midbody are smoothly connected.

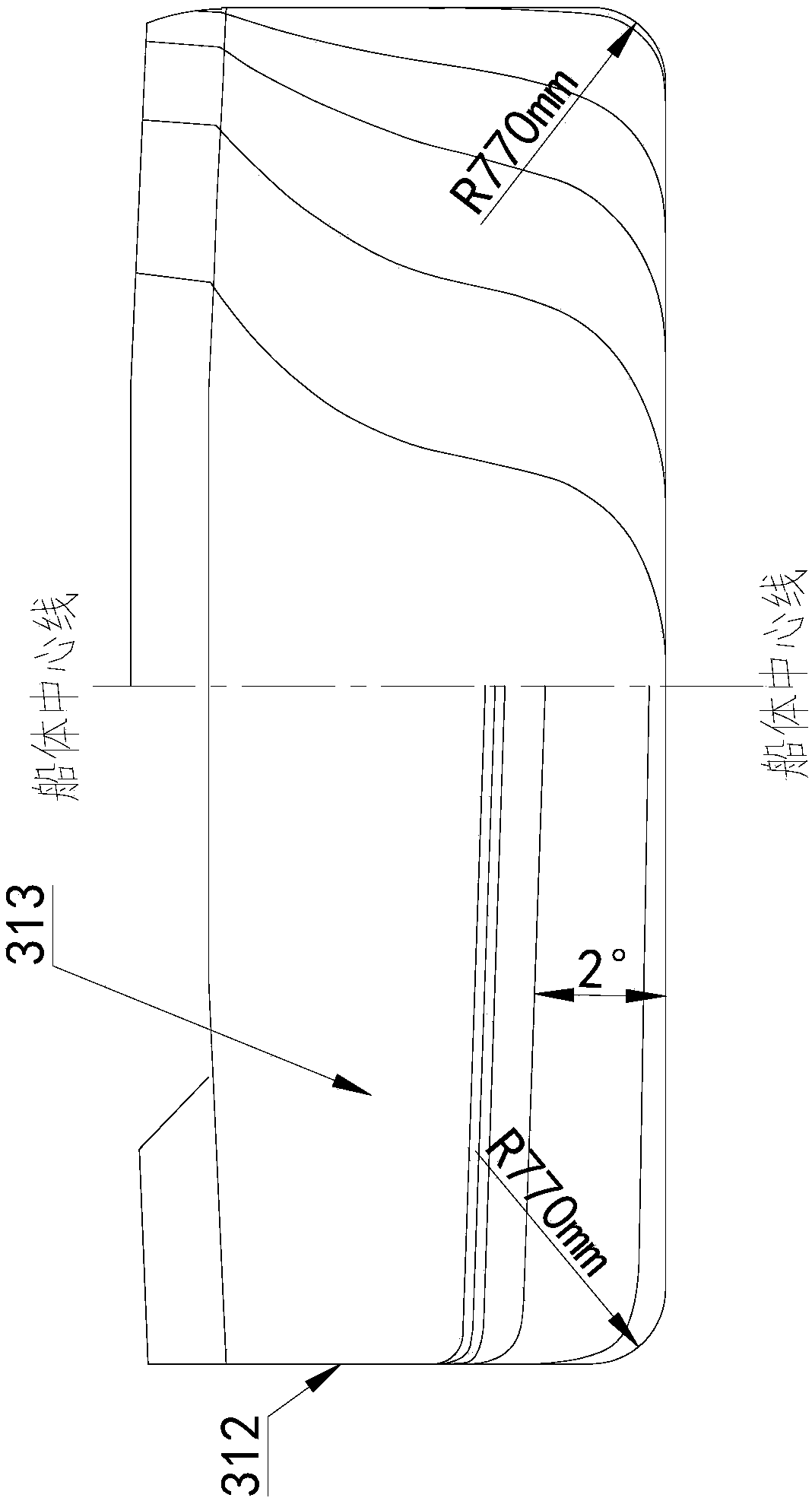

[0051] The outflow section 31 includes the bottom plate 311 of the outflow section, the side shell plate 312 of the outflow section and the stern seal plate 313; the bottom plate 311 of the outflow section is a horizontal plate; the side shell plate 312 uses a round bilge to connect the outflow Section ship bottom plate 311, t...

Embodiment 2

[0073] This embodiment provides a 70.5 meters, 2000-ton bulk carrier that adopts double straight-wing propeller 4, and the owner's scale is:

[0074] Total length L=70.5 meters; molded width B=13.9 meters; molded depth D=4.5 meters; draft T=3.30 meters;

[0075] Medium section coefficient Cm=0.992; L / B=5.072; B / T=4.212.

[0076] Such as figure 1 As shown, the longitudinal section lines of the hull bow 1, hull middle 2, and hull stern 3 are all smoothly connected.

[0077] At the center longitudinal section, the bow stern and the bottom plate adopt a circular arc transition with a radius of 1500 mm, and the bottom plate at the parallel center body gradually rises, and the transition section 32 of the stern adopts an inverse curve transition, and at the bottom plate 311 of the outflow section, Tend to level, in this horizontal section, straight wing propeller 4 is installed.

[0078] In this embodiment, the slope of the longitudinal section line of the bottom plate 311 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com