Self-service material frame used for circulation of produced parts

A material shelf and self-service technology, which is applied in the field of storage shelves, can solve the problems of easy misplacement or mistaking of goods, poor flexibility, and inconvenient movement of objects, so as to prevent objects from being wrong or falling, and prevent misplacement or mistaking , Improve the effect of space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

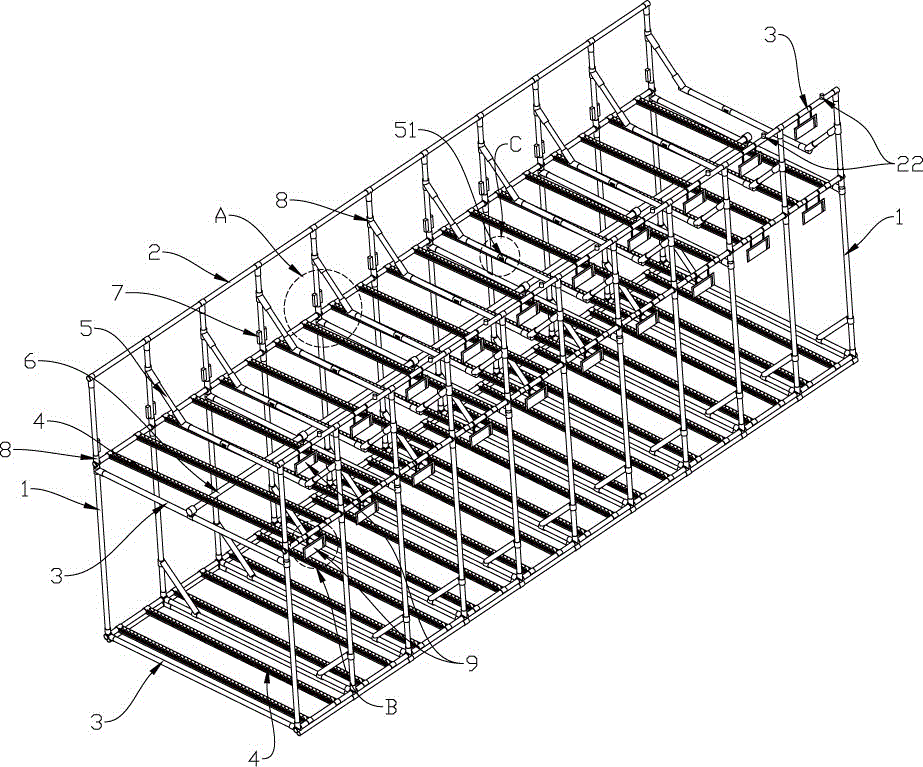

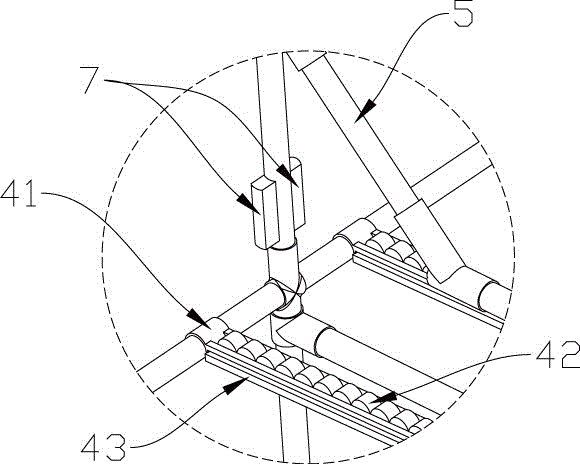

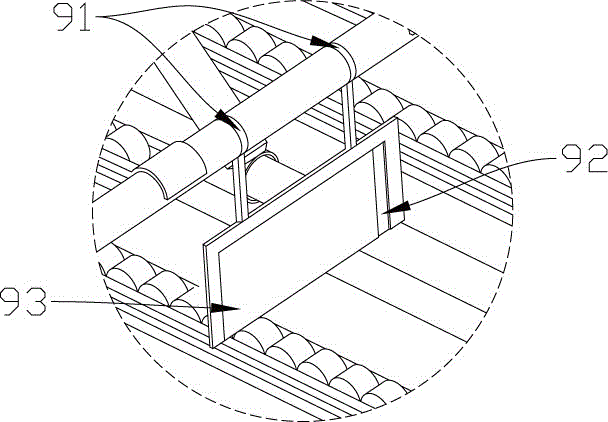

[0022] refer to Figure 1 to Figure 4 As shown, the assembled material rack used in the storage workshop includes a vertical support bar 1, a transverse support bar 2, and a shelf bar 3, and the vertical support bar 1, the transverse support bar 2, and the shelf bar 3 are assembled through a socket 8 Together, the shelf includes two layers of storage layers, and three or four layers can also be set according to needs. The storage layer is provided with a roller assembly 4, and the roller assembly 4 includes a mounting seat 43, and the mounting seat 43 is provided with There are several rollers 42, and the two sides of the mounting seat 43 are buckled on the lateral support rod 2 by the fastening parts 41, so the position and adjacent distance of the roller assembly 4 can be adjusted conveniently to adapt to different objects; the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com