Drum structure of hydraulic pipe cleaning machine

A technology for hydraulic pipes and washing machines, which is applied in the directions of cleaning methods using liquids, cleaning hollow objects, cleaning methods and utensils, etc., can solve the problems of poor cleaning efficiency and high cost, and achieves reduction of cleaning costs, improvement of cleanliness levels, and shortening of Effect of cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

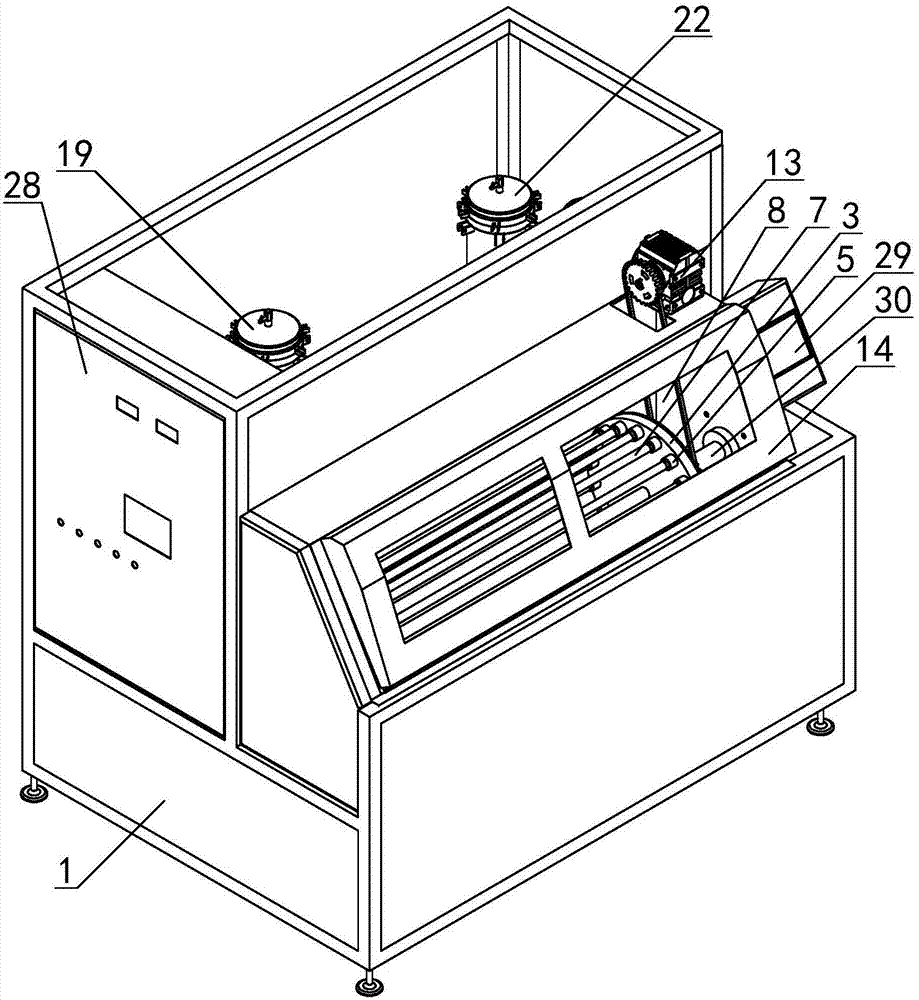

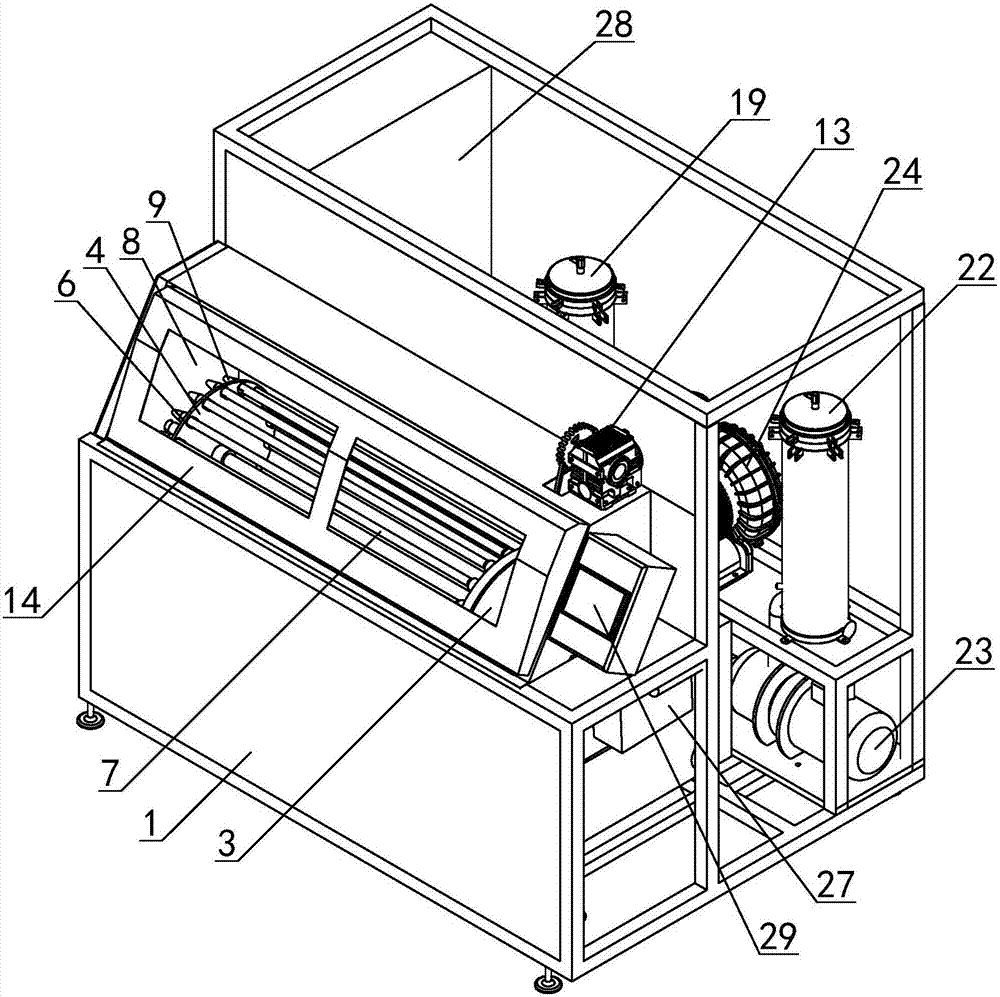

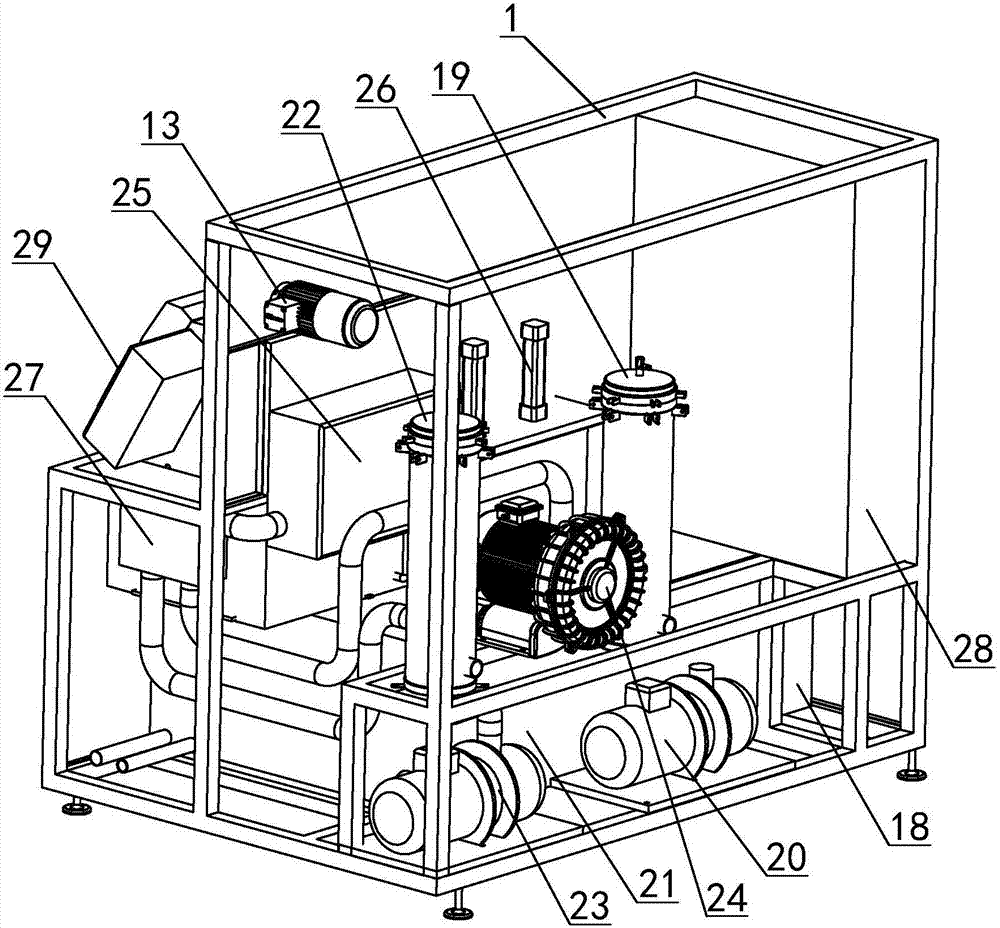

[0038] Example: see attached Figure 1~4 As shown, a drum structure of a hydraulic pipe cleaning machine, the cleaning machine includes a frame 1, and a drum structure connected to the frame 1, a cleaning unit, a rinsing unit and a drying unit. (In order to show the structural structure, the rack in the figure hides the side panel, top panel and back panel)

[0039] Such as Figure 5~14 As shown, the drum structure includes a drum and a water tank 2; the drum includes a first chucking disc 3, a second chucking disc 4 and a rotating shaft 31; the first chucking disc 3 and the second chucking disc The chucking discs 4 are arranged in parallel, and are all interspersed with the rotating shaft 31 by their hubs; on the surface of the first chucking disc 3 opposite to the second chucking disc 4, a plurality of hydraulic pipes are arranged. A positioning part 5, the first positioning part 5 of each hydraulic pipe is evenly distributed along the circumferential direction of the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com