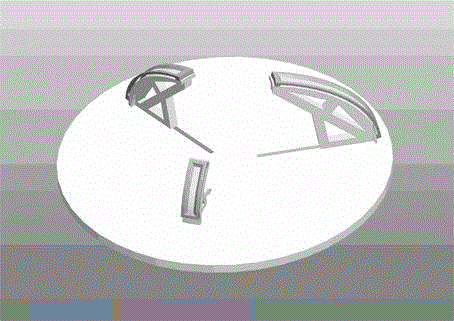

Welding fixture for ring on bottom of carrier rocket propellent tank

A technology for propellant storage tanks and launch vehicles, which is applied to the tooling field of circular friction stir welding at the bottom of multi-specification launch vehicle propellant storage tanks. problems, to achieve the effect of improving the utilization rate of tooling, simplifying the structure, saving time and manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the following examples are only used to illustrate the present invention but not to limit the scope of the present invention.

[0027] It can be seen from the background technology that today's storage tanks have diversified tasks, and the processing size is becoming more and more complicated. The longitudinal seam welding of the melon petals at the bottom of the tank is the welding structure with the largest number. In reality, it is necessary to process the longitudinal seams of melon petals of various sizes and specifications at the same station, and the production of tooling with various sizes and the repeated lifting and positioning of the tooling become the bottleneck that limits the efficiency of the product.

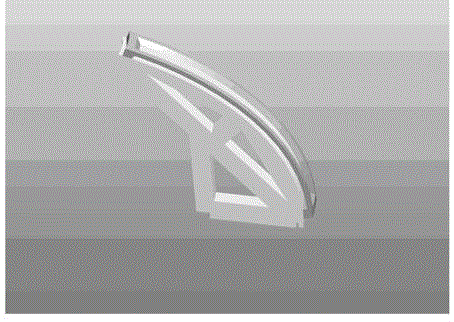

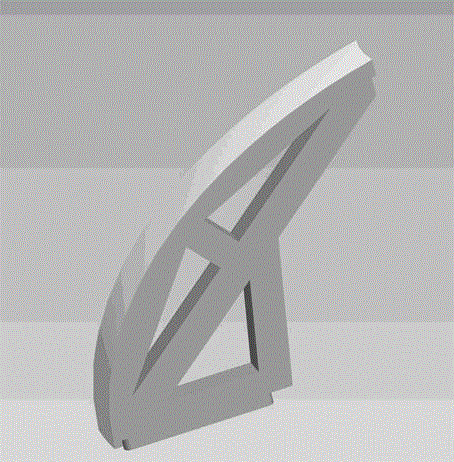

[0028] The invention provides a frock for multi-size longitudinal seam welding at the bottom of a bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com