Flexible fixture applicable to workpieces with irregular shapes

A flexible fixture and irregular technology, applied in the direction of manufacturing tools, metal processing machinery parts, clamping, etc., can solve the problems of inconvenient clamping of irregular workpieces, achieve the effect of improving clamping degree and reducing the probability of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

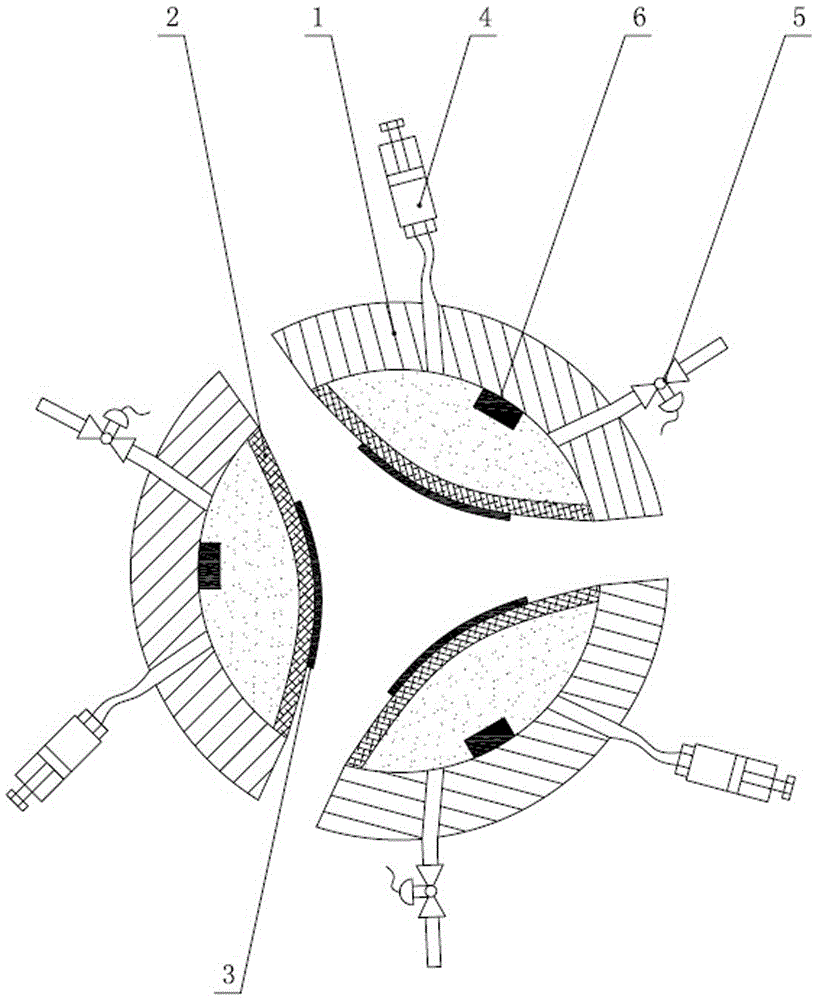

[0016] All the curved baffles 1 are covered with flexible airbags 2 , and the curved baffles 1 also have air inlets and air outlets that pass through the curved baffles 1 and communicate with the flexible airbags 2 . The air intake hole is connected to the air pump 4, and the air outlet hole is connected to the air outlet regulating valve 4. The air outlet regulating valve 4 can be a solenoid valve equipped with a wireless transmission module for wireless communication with the controller. In order to better control the clamping degree, a pressure sensing sheet 3 is provided on the working surface where the flexible airbag 2 is in contact with the workpiece. The pressure sensing sheet 3 and the air pump 4 are respectively connected to the controller with wireless signals. 3 The transmitted signal judges whether the clamped part is clamped, and the clamping degree is controlled by adjusting the air pump 4 and the air outlet regulating valve 4.

[0017] In order to detect the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com