Adjusting device used for assembly of aircraft wing

A technology of adjusting device and wing, applied in aircraft assembly and other directions, can solve problems such as hidden safety hazards of aircraft, damage to aircraft wing structure, large difference in wing volume and height, etc., to reduce the number of handling times and the operation process is fast Efficient and favorable for transportation and transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

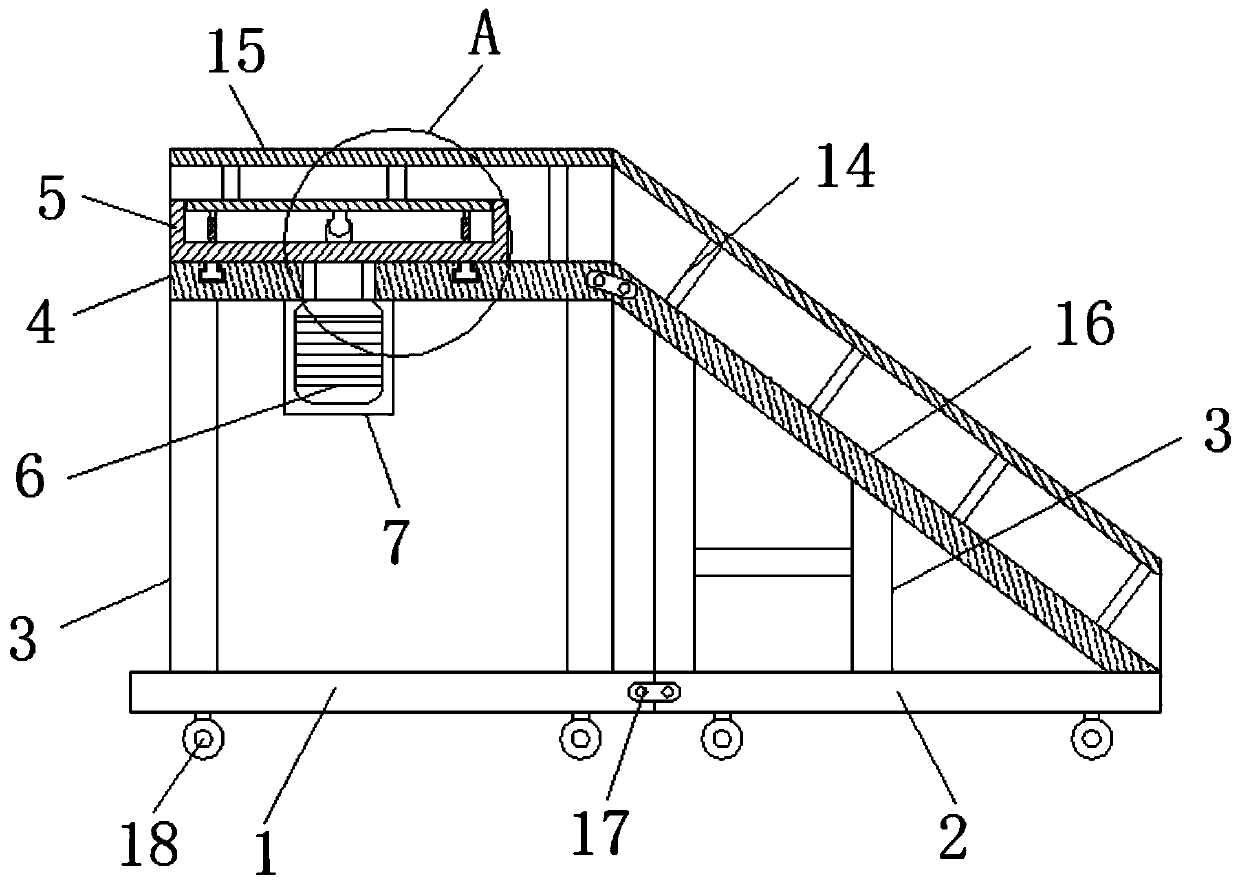

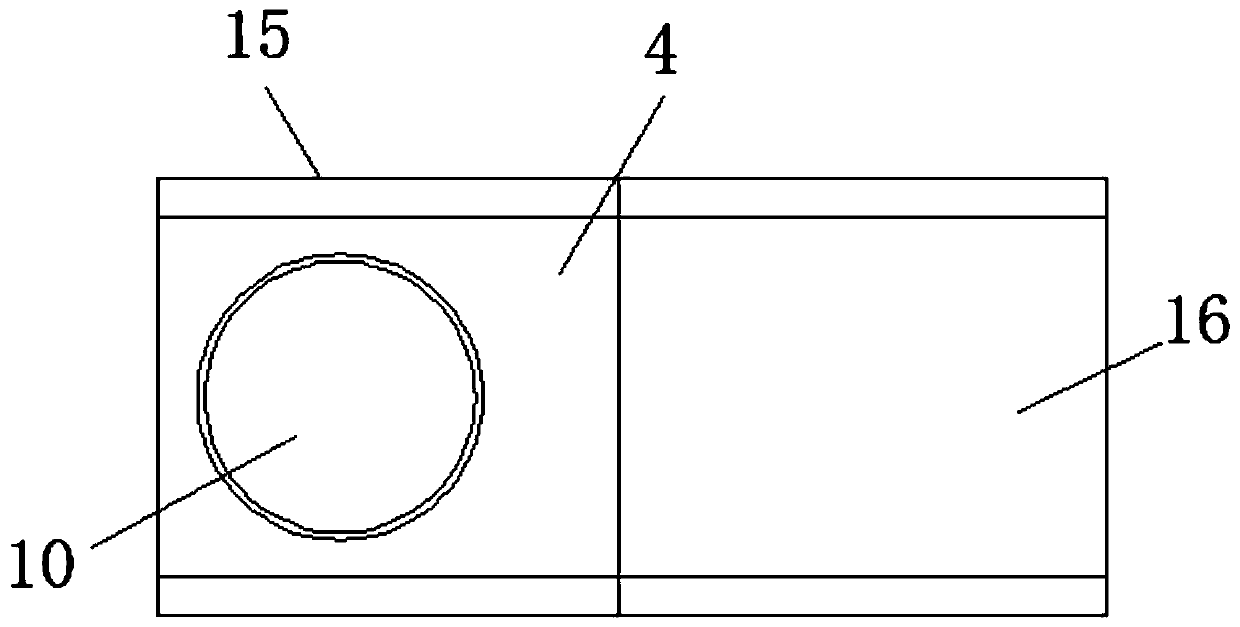

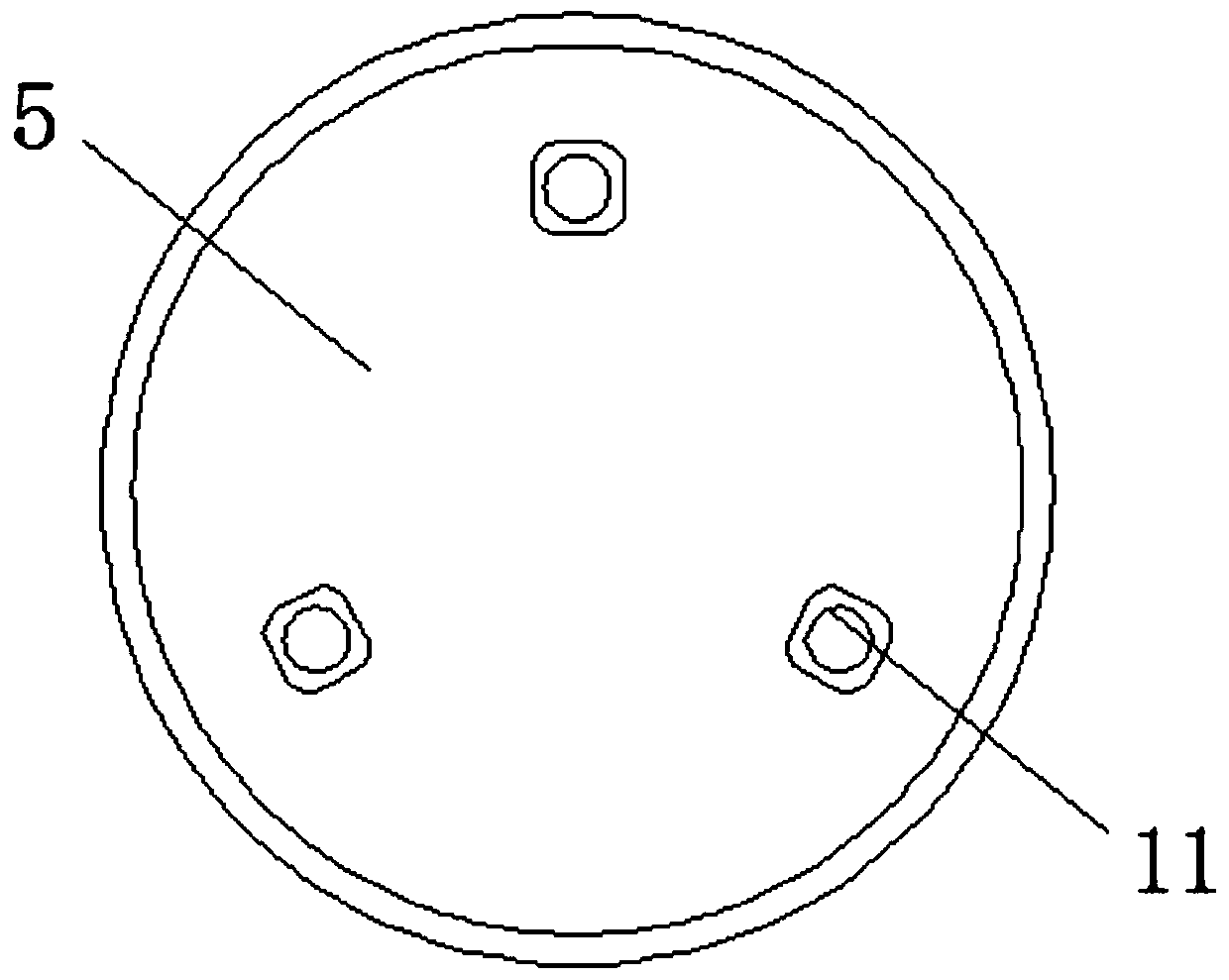

[0044] like Figure 1-4 As shown in the figure, an adjusting device for assembling an aircraft wing includes a base plate 1 of a mounting frame and a base plate 2 of a lifting frame, an operation platform 4 is arranged above the base plate 1 of the installation frame through a support column 3, and an operation platform 4 is arranged below the operation platform 4 There is a motor frame 7, a motor 6 is arranged in the motor frame 7, a base 5 is arranged above the operation platform 4, and the symmetrical center of the lower end of the base 5 is fixedly connected with one end of the output shaft of the motor 6, which is controlled by the motor 6 The base 5 is rotated to realize the adjustment of the direction of the adjusting device when the aircraft wing is assembled. The upper end of the base 5 is sleeved with an operation panel 10, and at least three sets of mutually symmetrical hydraulic cylinders 11 are arranged between the operation panel 10 and the base 5. Adjustment of...

Embodiment 2

[0055] like Figure 1-4 As shown in the figure, an adjusting device for assembling an aircraft wing includes an installation frame base plate 1 and a lifting frame base plate 2, an operation platform 4 is provided above the installation frame base plate 1 through a support column 3, and an operation platform 4 is arranged below the operation platform 4. There is a motor frame 7, a motor 6 is arranged in the motor frame 7, a base 5 is arranged above the operation platform 4, and the symmetrical center of the lower end of the base 5 is fixedly connected with one end of the output shaft of the motor 6, which is controlled by the motor 6 The base 5 is rotated to adjust the direction of the aircraft wing; the upper end of the base 5 is sleeved with an operation panel 10, and at least three sets of mutually symmetrical hydraulic cylinders 11 are arranged between the operation panel 10 and the base 5. Adjusting the hydraulic cylinder 11 realizes the adjustment of the inclination angl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Longitudinal modulus of elasticity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com