Mould lifting device of three-dimensional bag forming machine

A lifting device and molding machine technology, applied in envelope/bag manufacturing machinery, packaging, transportation and packaging, etc., can solve the problems of mold shift, slow response of the lifting device, and loud motor noise, and achieve low noise, fast response, Long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

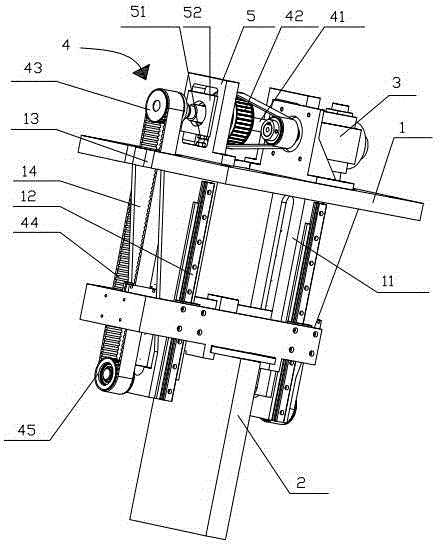

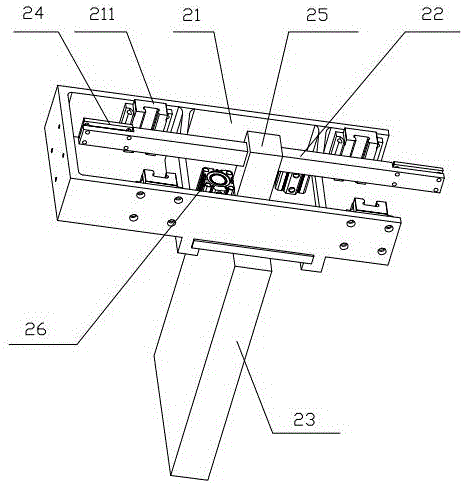

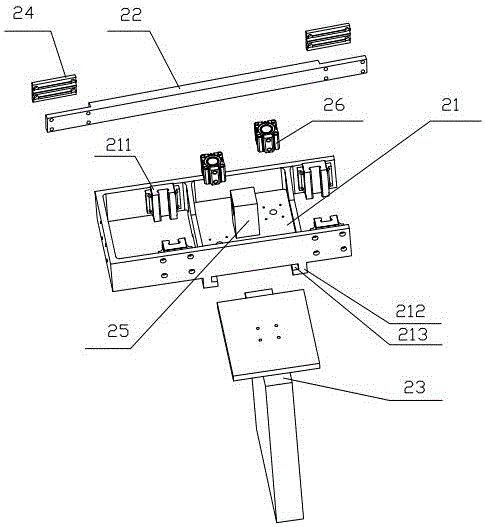

[0021] Depend on figure 1 combine figure 2 , 3 , 4, a three-dimensional bag forming machine mold lifting device, including a base 1 and a mold assembly 2, the top of the base 1 is provided with a drive 3, the drive is a servo motor, the drive The part 3 is connected with the mold assembly 2 through the transmission mechanism 4. The mold assembly 2 is arranged under the base 1 and slides up and down on the base 1. The transmission mechanism 4 includes a transmission shaft 41 and a driving part 3 The connected first synchronous wheel 42, the first synchronous wheel 42 is sleeved on the transmission shaft 41 and linked with the transmission shaft 41, the two ends of the transmission shaft 41 are symmetrically provided with the second synchronous wheel 43, The second synchronous wheel 43 is connected with the mold assembly 2 through a synchronous belt 44 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com