3D printer using ceramic as raw material

A 3D printer and raw material technology, applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of unreliable lifting motion of molding platform, unreasonable laser optical path design, and harsh operating environment for operators, and achieves easy popularization and use, simple structure , the effect of easy light path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

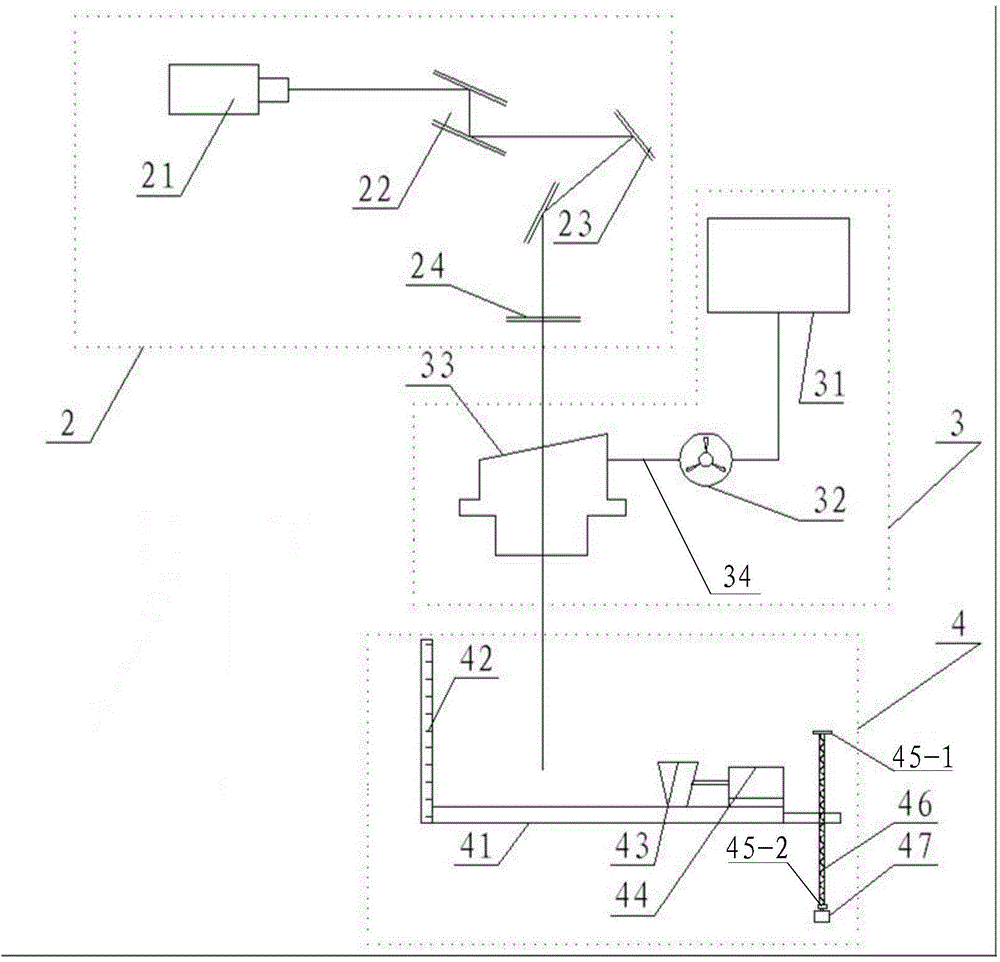

[0024] like figure 1 As shown, the present invention includes a laser head assembly 2, an exhaust assembly 3 and a forming platform assembly 4, the laser head assembly 2 includes a laser 21, an adjustment optical path group mirror 22 arranged in front of the laser 21, The XY scanning galvanometer 23 in front of the optical path group mirror 22 and the focusing lens 24 arranged under the XY scanning galvanometer 23; the forming platform assembly 4 includes a forming platform 41 and a material spreading mechanism installed on the forming platform 41 , the spreading mechanism is composed of a spreading hopper 43 and a cylinder 44 connected with the spreading hopper 43, a cursor ruler 42 is installed on one side of the forming platform assembly 4, and a A lift screw pair 46 that drives the forming platform 41 to rise and fall, a lift motor 47 for driving the lift screw pair in the lift screw pair 46 to rotate is installed at the bottom of the lift screw pair 46 , and the The top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com