A tilting four-rotor long-endurance composite aircraft

A technology for tilting quadrotors and aircrafts, which is applied to aircrafts, unmanned aircrafts, and rotorcrafts. It can solve problems such as technical difficulty and high cost, high structural strength requirements, and complex tilting mechanisms, and achieve flight control systems. Simplification, efficiency improvement, high safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

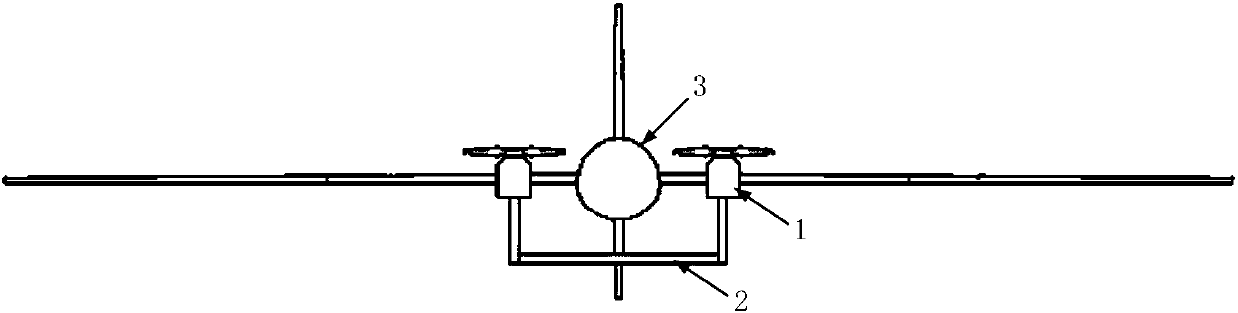

[0023] The tilting four-rotor long-endurance composite aircraft of the present invention includes a four-rotor power system 1, a tilting mechanism 2 and an aircraft main body 3, such as figure 1 shown.

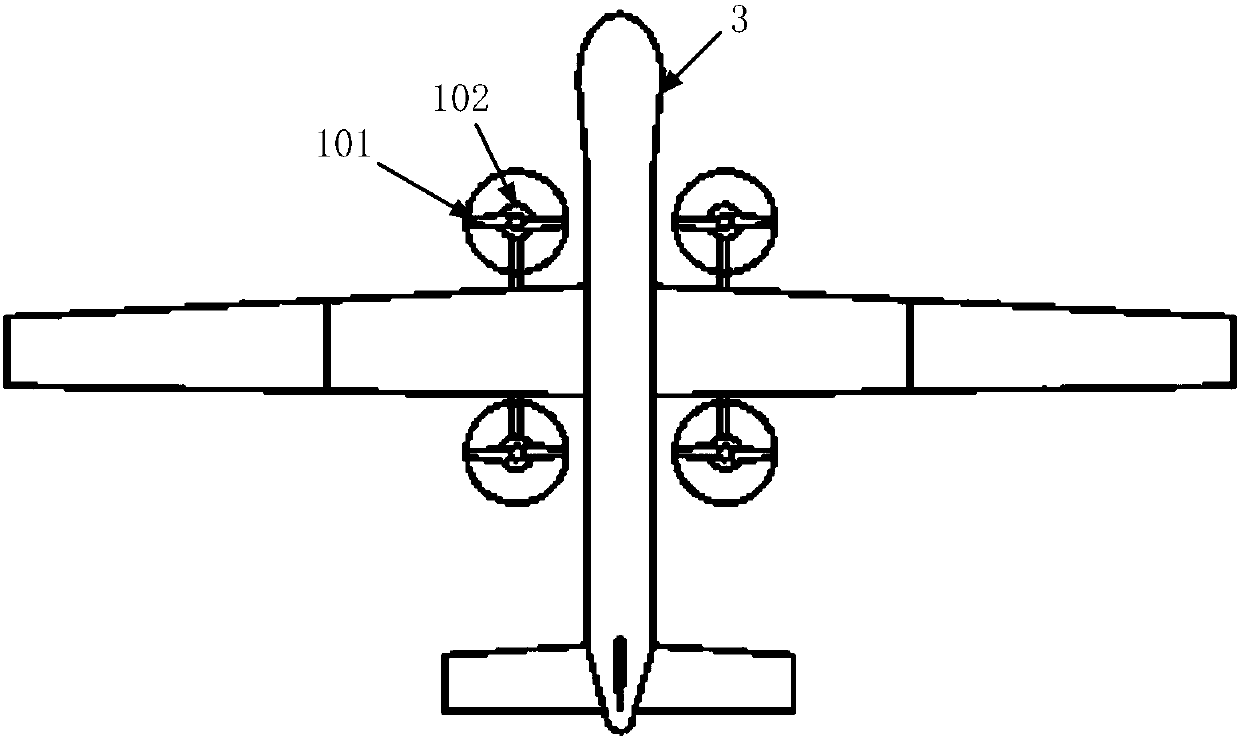

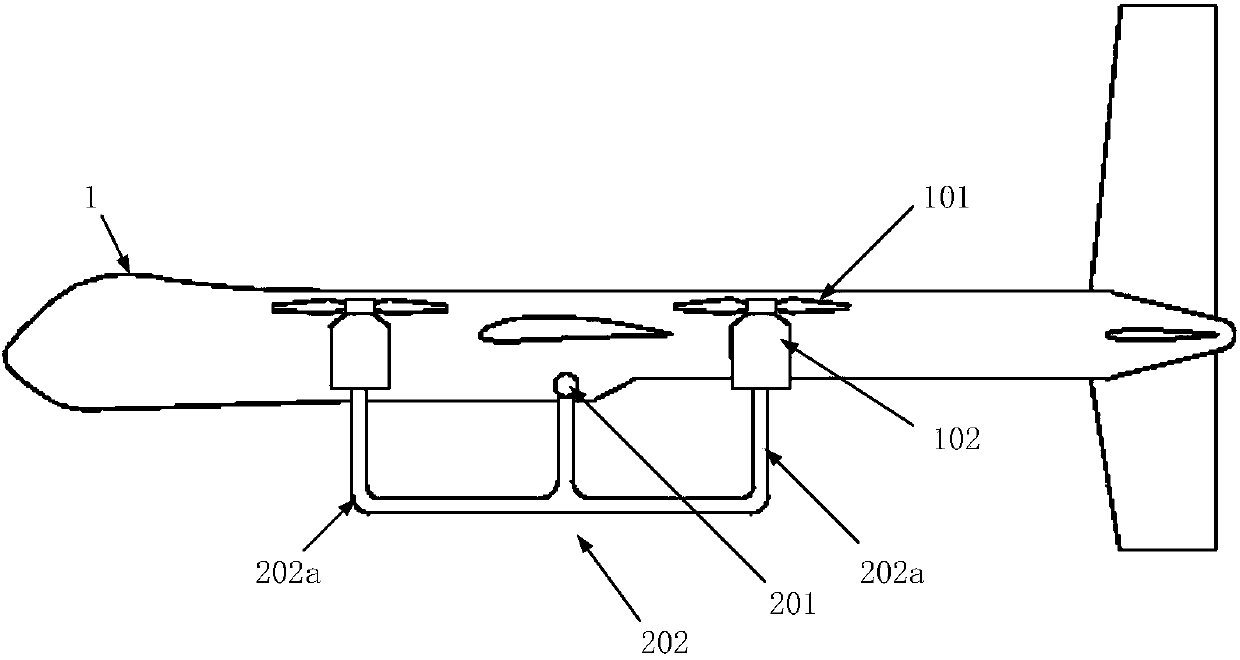

[0024] The four-rotor power system 1 is composed of four propellers 101 and four propeller engines 102 to provide the power system for the flight power of the main body of the aircraft, such as figure 2 shown. Each propeller 101 corresponds to a propeller motor 102, which is fixedly installed on the output shaft of the propeller motor 102, and the propeller 101 is driven to rotate by the propeller motor 102 to provide flight power for the aircraft. Four propeller engines 102 are all installed on the tiltable mechanism 2 .

[0025] The tilting mechanism 2 includes a tilting shaft 201 and a rotor system mounting bracket 202, such as image 3 , Figure 4 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com