Carriage butt-joint device

A docking device and carriage technology, which is applied in the directions of storage device, loading/unloading, transportation and packaging, etc., can solve the problems of easy collision, garbage pollution of longitudinal moving device, high service life of longitudinal moving device, and achieve low equipment failure rate, Long service life and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the objectives, features, and advantages of the present invention more obvious and understandable, the specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

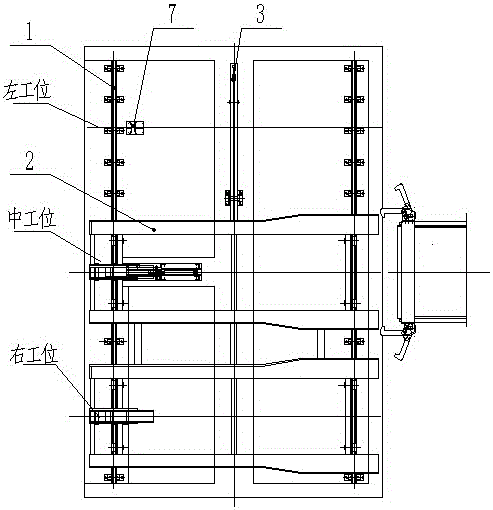

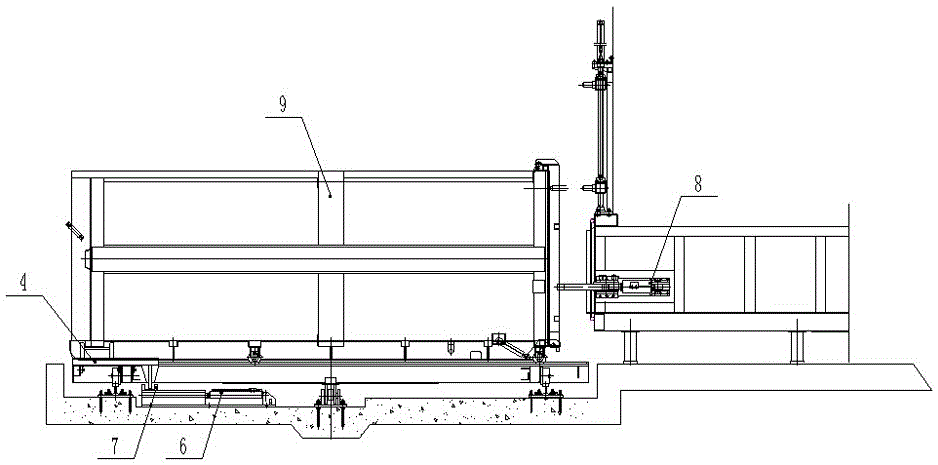

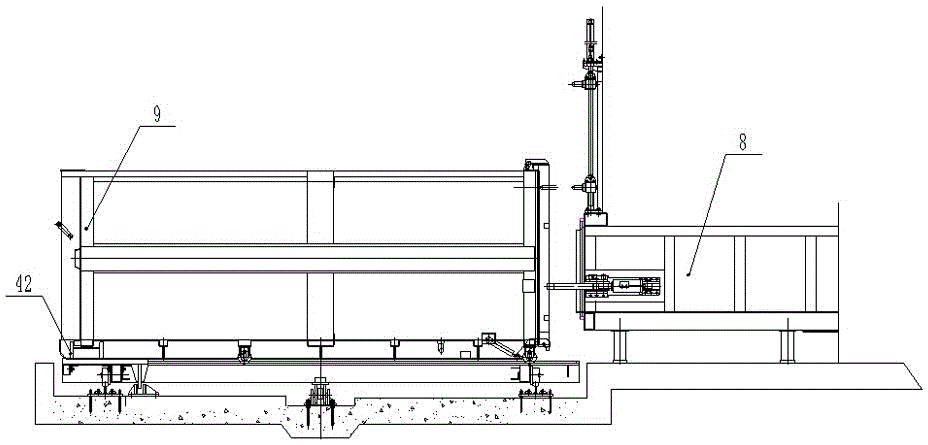

[0025] Please refer to Figure 1-Figure 7 , figure 1 It is a schematic diagram of a specific implementation of the car docking device provided by the present invention.

[0026] The car docking device includes: two laterally moving guide rails 1 fixed side by side on the foundation. The laterally moving guide rail 1 is divided into a left station, a middle station and a right station according to the movement of the car 9. The traverse bracket 2 moves back and forth along the traverse guide rail 1 under the action of the traverse cylinder 3, that is, moves between the three stations of the traverse guide rail 1. A longitudinal sliding trolley 4 is installed at one end of the traverse bracket 2 far from the compressor 8, and the lon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com