Flocculation equipment

A kind of equipment and flocculation technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of poor water purification effect, suspended solids or impurities residue, poor flocculation effect, etc. problems, to achieve the effect of easy assembly, low equipment failure rate and low maintenance rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

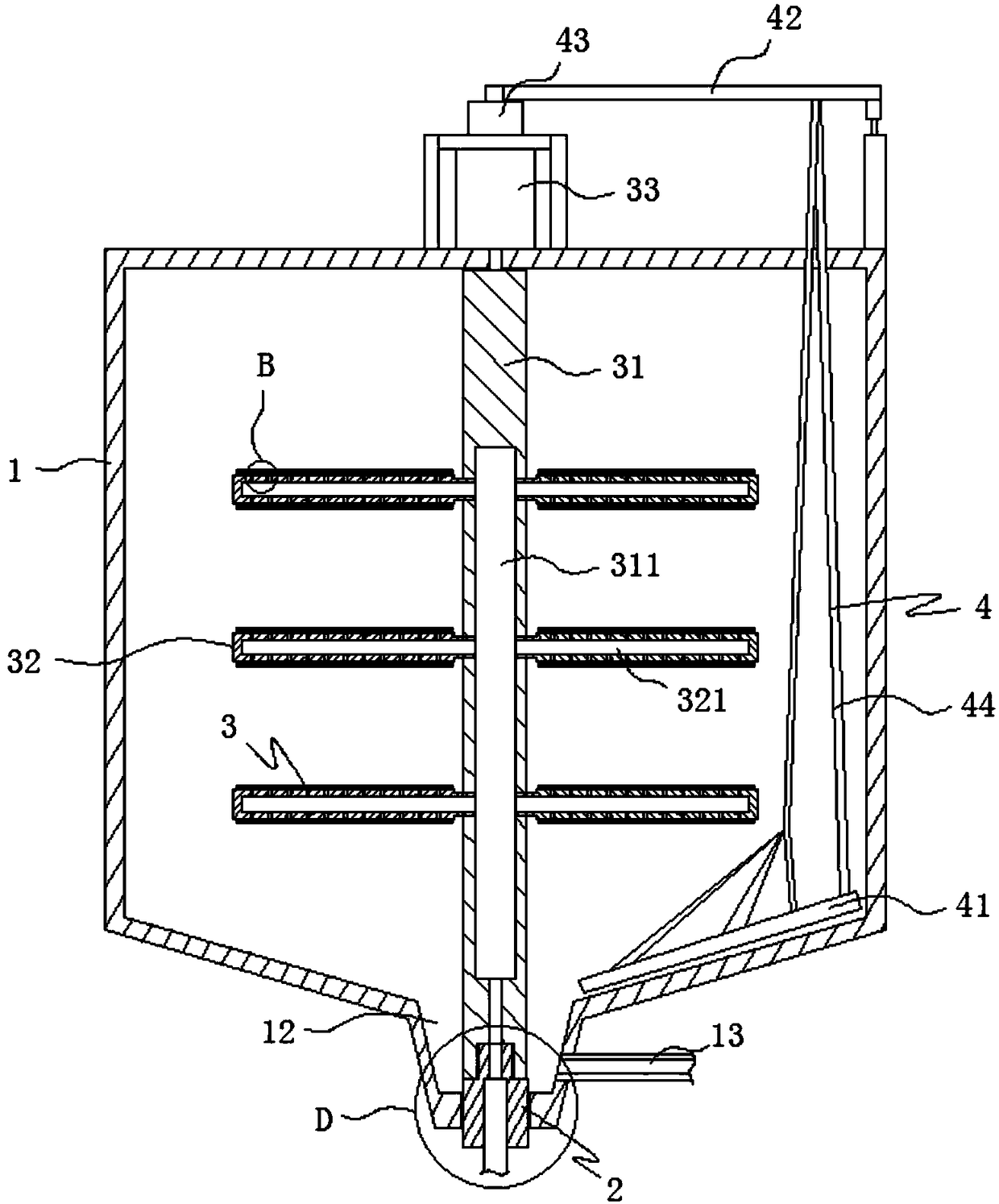

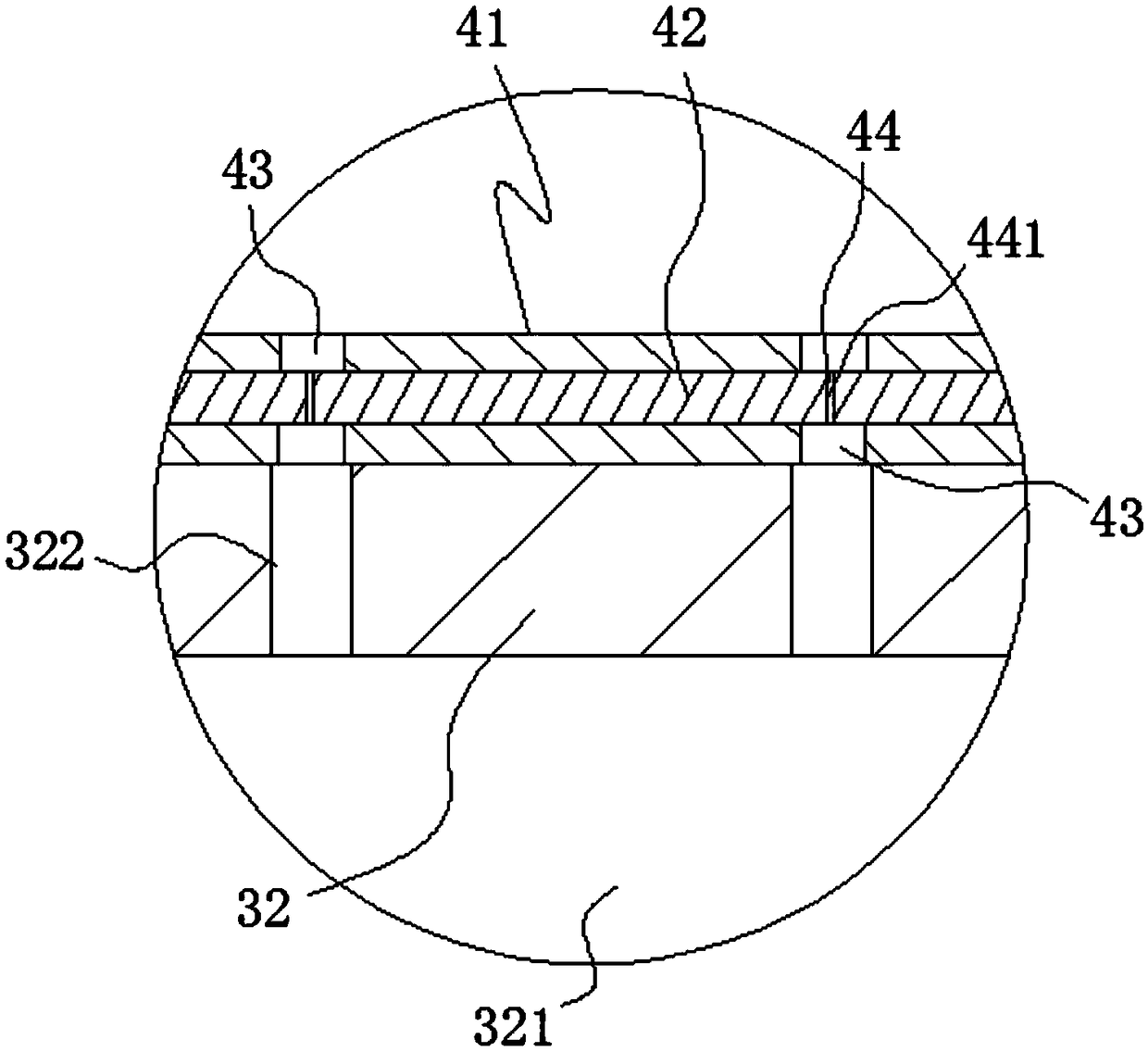

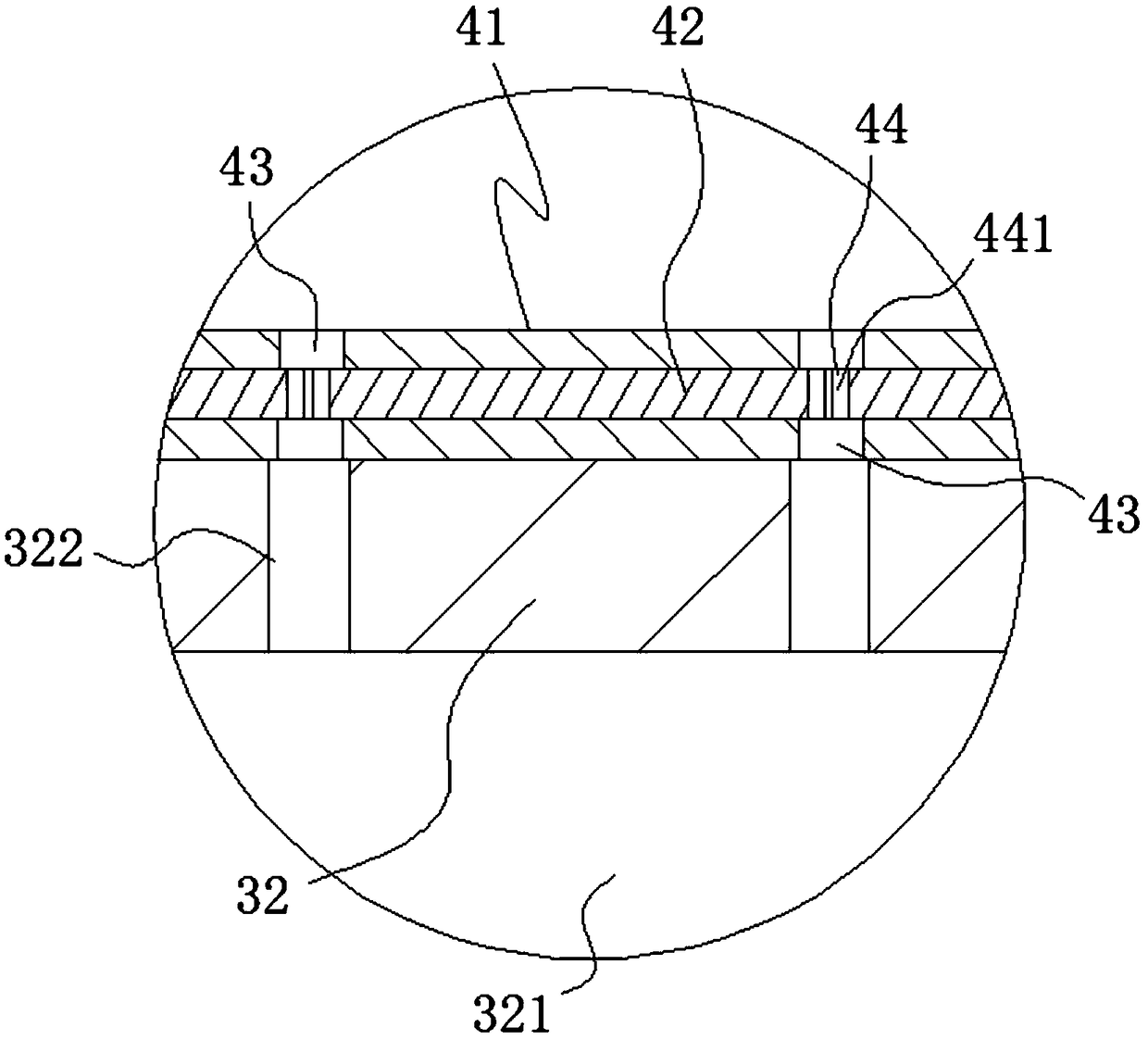

[0022] Such as Figure 1-5 Shown, a kind of flocculation equipment, comprises flocculation tank 1, the feeding device 2 that is connected with this flocculation tank, is located in this flocculation tank and the stirring device 3 that cooperates with this feeding device and scraper equipment 4; Said feed The device 2 is used to put a flocculant into the flocculation tank, and the flocculant is polyaluminium chloride directly purchased on the market; specifically, the stirring device 3 includes a stirring shaft 31 made of stainless steel and a stirring paddle 32 made of stainless steel And drive member 33; Described stirring paddle 32 is screwed on the described stirring shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com