Mixed bed recovered acid and alkali liquid preparing system

A mixed-bed, acid-base technology, applied in ion exchange regeneration, mixers, mixer accessories, etc., can solve the problems of high failure rate of pipeline equipment along the line, large fluctuation of acid-base concentration configuration, poor regeneration and recovery effect of resin performance, etc. Improve the regeneration effect of the mixed bed, increase the output of the mixed bed, and reduce the difficulty of operation and equipment failure rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

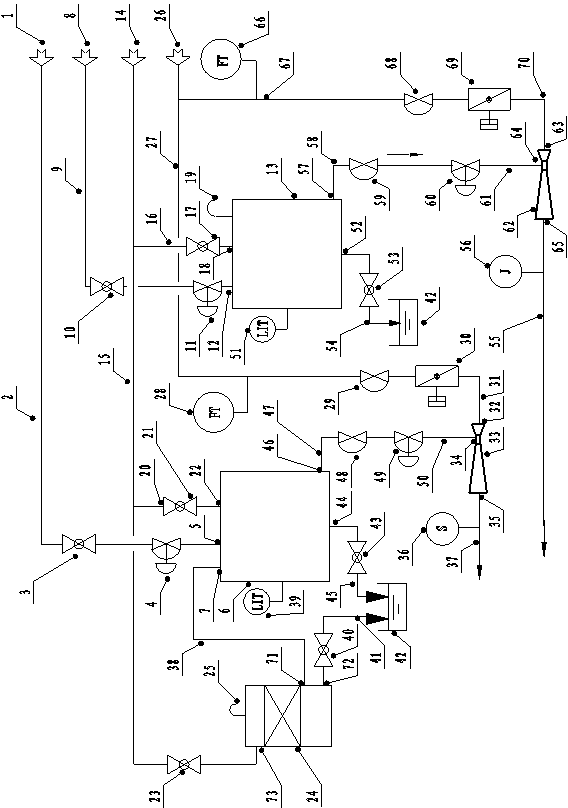

[0018] figure 1 The described mixed-bed regenerated acid-base solution preparation system includes an acid metering tank 6, an alkali metering tank 13, a first injector 33, a second injector 62, and a demineralized water pipe 27. The top of the acid metering tank 6 has an acid inlet 5, The side of acid metering tank 6 is equipped with meter 39 for acid liquid, the top of alkali metering tank 13 has alkali inlet port 12 and alkali metering tank overflow pipe 19, and the side of alkali metering tank 13 is equipped with alkali liquid level gauge 51, The acid outlet 46 at the bottom side of the acid metering tank 6 is connected with the first injector acid liquid inlet 34 of the first injector 33 with the acid delivery pipe 47, and the first injector outlet 35 of the first injector 33 is connected with Mixed bed alkali inlet pipe 37, acid concentration meter 36 is installed on the mixed bed alkali inlet pipe 37; The lye inlet 64 of the device is connected, and the second i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com