Sweeping brush piece for feeding machine

A cleaning brush and feeding machine technology, which is applied in the field of tobacco machinery, can solve the problems of mildew, waste, qualitative change, etc., and achieve the effects of prolonging the service life, good cleaning effect, and not easy to shed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

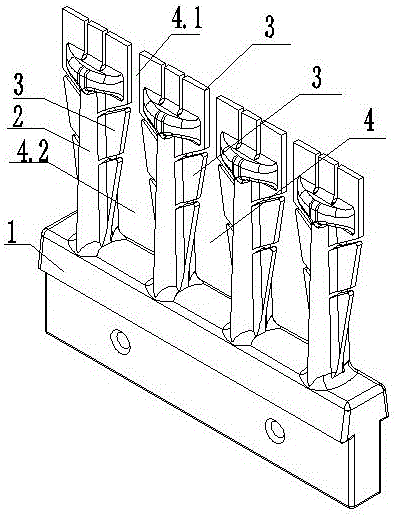

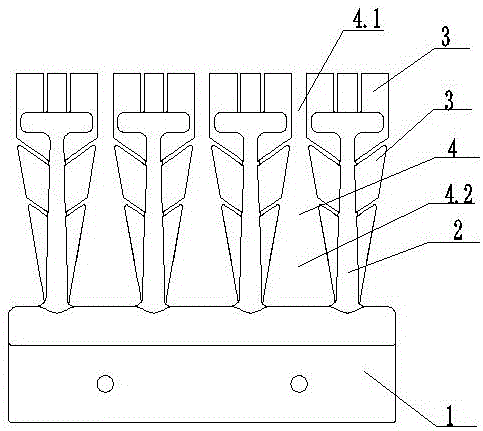

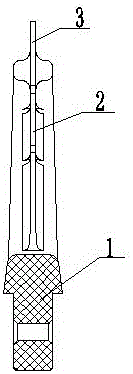

[0017] Now in conjunction with accompanying drawing, the present invention will be further described.

[0018] see Figure 1-4 , feeder cleaning brushes, including a fixed seat 1 and a plurality of scrapers 2, the fixed seat 1 and the scraper 2 are integrally formed, and the top and both sides of the scraper 2 are designed with scraping teeth 3; located on the top of the scraper 2 The lower parts of the scraping teeth 3 on both sides extend to both sides of the scraper blade 2, and the accommodation space 4 for the screw is formed between the corresponding side scraper teeth 3 of two adjacent scraper blades 2, so that the scraper teeth 3 on the top of the scraper blade 2 The transition with the scraping teeth 3 on both sides of the scraper blade 2 is tight, reducing the cleaning blind area. The width of the upper part 4.1 of the accommodation space is equal to the diameter of the screw 5, and the width of the lower part 4.2 of the accommodation space is greater than the diame...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap