Bottle unloading method and device

A transmission device and bottle stacking technology, which is applied in the field of material transmission, can solve the problems of manpower consumption, low accuracy, and low efficiency, and achieve the effects of reducing exhaust emissions, short transmission time, and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail with reference to the accompanying drawings and embodiments:

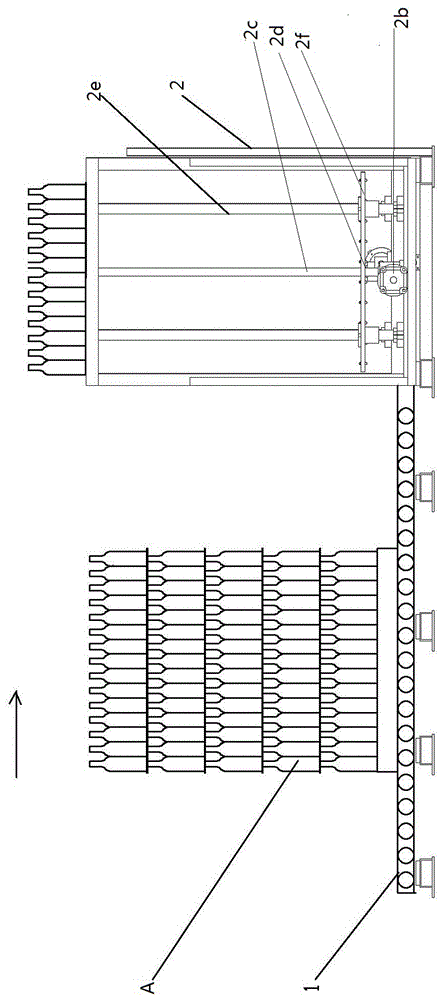

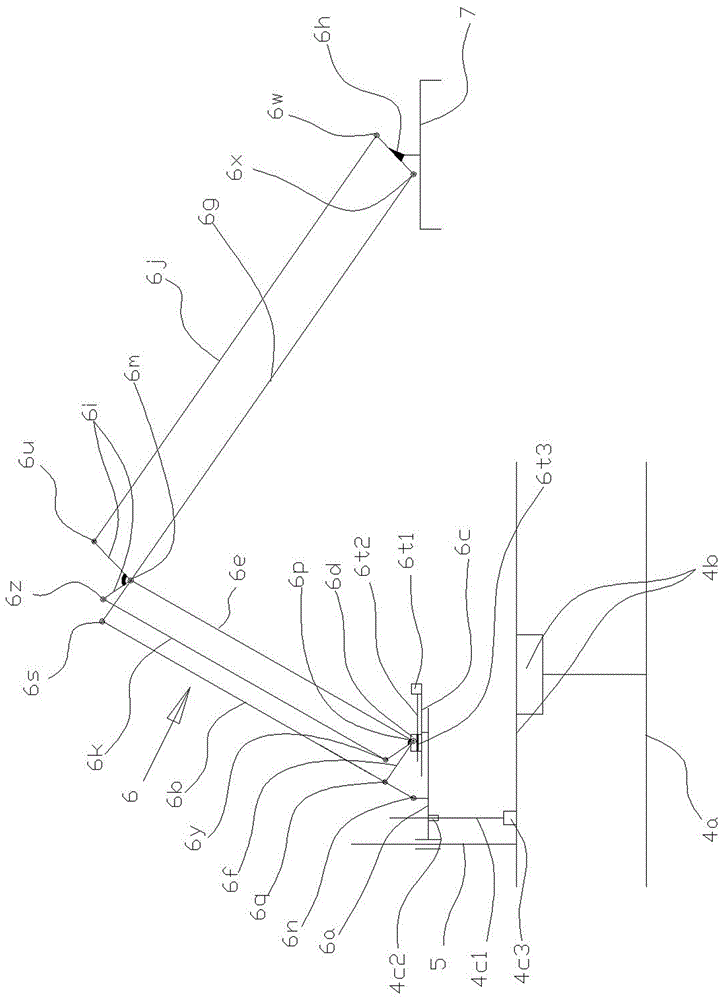

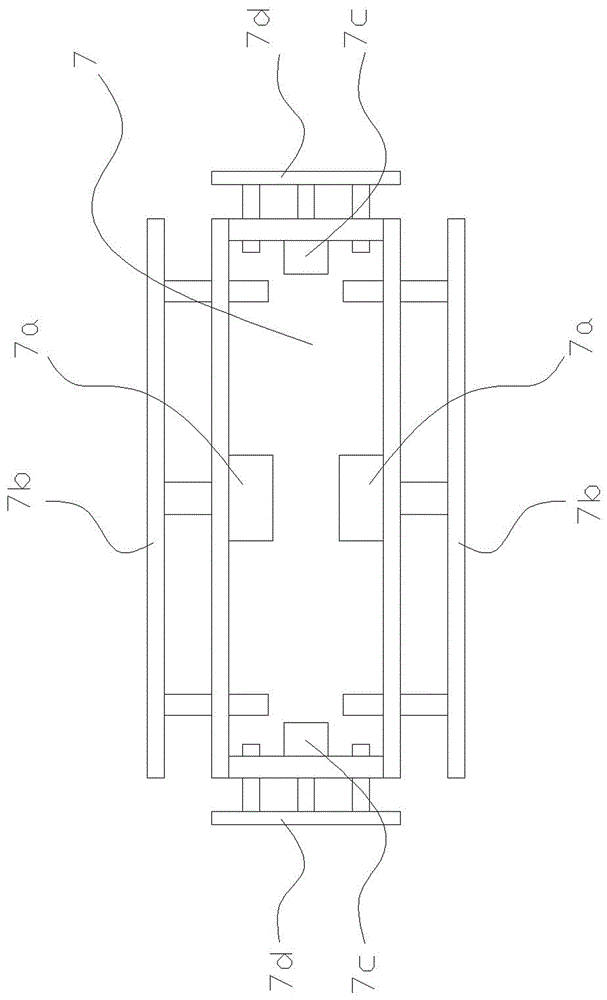

[0014] As shown in the figure, the bottle unloading device of the present invention is realized in this way, including a low-level conveyor 1 (roller or belt conveyor), a lift connected to the low-level conveyor 1, a high-level conveyor 3 located on the top of the lift 2 ( Roller or belt conveyor), the bottle stack conveyor 4, the bottle stack conveyor 4 includes a base 4a, a power turntable 4b arranged on the base 4a, an upper and lower power drive mechanism 4c (including a motor The screw 4c1 driven by 4c3, the screw sleeve 4c2 sleeved on the screw 4c1), the horizontal movement mechanism 6 which moves up and down along the vertical guide 5 driven by the up and down power drive mechanism 4c, the power driven by the horizontal movement mechanism 6 The frame 7, the transverse moving mechanism 6 includes a movable frame 6a fixed on the screw sleeve 4c2, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com