Infrared heating ironing roller combustion device

A combustion device, ironing roller technology, applied in the direction of burner, combustion method, combustion type, etc., can solve the problems of high energy consumption, high energy consumption of electric heating ironing roller, no oil boiler heating system, etc., to achieve faster Heating process, good energy-saving effect, and the effect of saving high-power electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

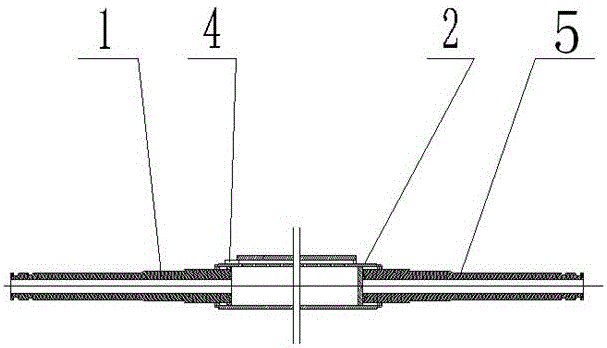

[0017] Such as figure 1 As shown, an infrared heating ironing roller combustion device includes a left shaft head 1, a gas pipe 2, an igniter 4 and a right shaft head 5; one end of the left shaft head 1 is connected to a gas pipe, and the left shaft head 1 The other end of the gas pipe 2 is connected to one end of the gas pipe 2, the other end of the gas pipe 2 is connected to one end of the right shaft head 5, and the other end of the right shaft head 5 is sealed; the gas pipe 2 is axially provided with a set of gas holes, the surface of the gas pipe 2 is coated with a high emissivity infrared coating; each group of gas holes includes three rows of gas holes uniformly distributed, and the radial angle range of each group of gas holes is 10 ° ~ 30 °, the diameter of the gas holes It is 3mm; it is located at the junction of the left shaft head 1 and the gas pipe 2, and the gas pipe 2 is provided with an igniter 4; wherein, the gas pipe 2 is made of ceramics.

Embodiment 2

[0019] Such as figure 1 As shown, an infrared heating ironing roller combustion device includes a left shaft head 1, a gas pipe 2, an igniter 4 and a right shaft head 5; one end of the left shaft head 1 is connected to a gas pipe, and the left shaft head 1 The other end of the gas pipe 2 is connected to one end of the gas pipe 2, the other end of the gas pipe 2 is connected to one end of the right shaft head 5, and the other end of the right shaft head 5 is sealed; the gas pipe 2 is axially provided with two sets of Gas holes, the surface of the gas pipe 2 is coated with a high-emissivity infrared coating; each group of gas holes includes three rows of gas holes uniformly distributed, and the radial angle range of each group of gas holes is 10 ° ~ 30 °. The diameter is 2 mm; it is located at the junction of the left shaft head 1 and the gas pipe 2, and the gas pipe 2 is provided with an igniter 4; wherein, the gas pipe 2 is made of ceramics.

Embodiment 3

[0021] Such as figure 1 As shown, an infrared heating ironing roller combustion device includes a left shaft head 1, a gas pipe 2, an igniter 4 and a right shaft head 5; one end of the left shaft head 1 is connected to a gas pipe, and the left shaft head 1 The other end of the gas pipe 2 is connected to one end of the gas pipe 2, the other end of the gas pipe 2 is connected to one end of the right shaft head 5, and the other end of the right shaft head 5 is sealed; the gas pipe 2 is axially provided with three groups of gas holes, the surface of the gas pipe 2 is coated with a high emissivity infrared coating; each group of gas holes includes three rows of gas holes uniformly distributed, and the radial angle range of each group of gas holes is 10 ° ~ 30 °, the diameter of the gas holes It is 1 mm; it is located at the connection between the left shaft head 1 and the gas pipe 2, and the gas pipe 2 is provided with an igniter 4; wherein, the gas pipe 2 is made of ceramics.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com