Dredger

A technology for dredging ships and hulls, applied in special purpose ships, mechanically driven excavators/dredgers, ships, etc., can solve the problems of wasting manpower and material resources, low dredging efficiency, etc., and achieve the effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

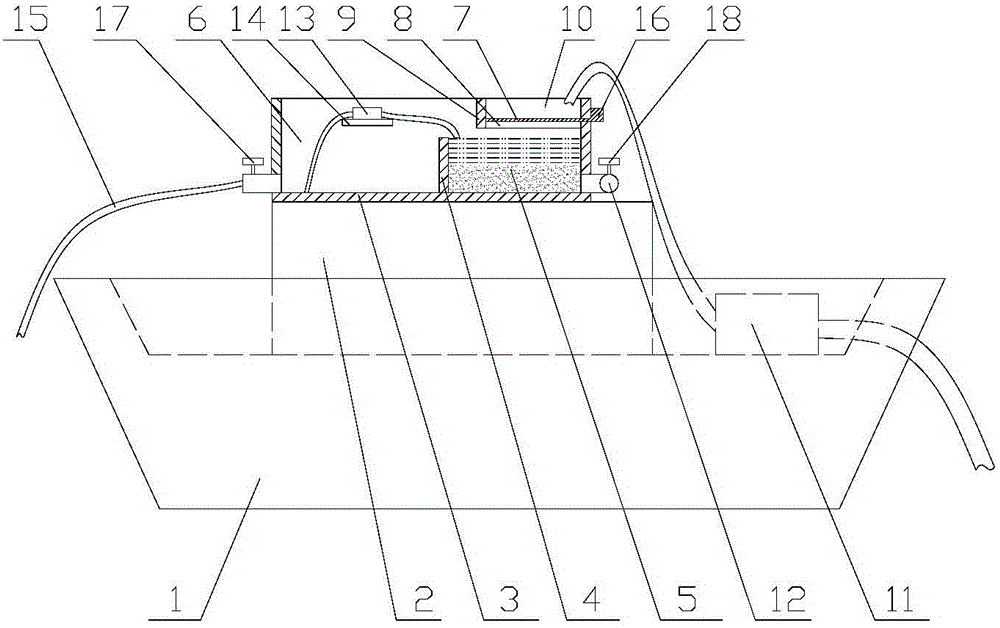

[0020] see figure 1 , is a preferred embodiment of the dredging ship, comprising a hull 1 of the dredging ship, a silt holding box 2 and a silt collecting device arranged on the dredging ship hull 1, and the silt holding box 2 is arranged at the rear of the hull . It also includes a silt separation device arranged on the silt storage box 2, the silt separation device includes a separation box 3, the top of the separation box 3 is an opening, and the bottom plate of the separation box 3 is fixed on the silt storage box 2 by bolts, separates A partition plate 4 arranged transversely along the hull 1 is welded in the box 3, the lower end of the partition plate 4 is welded to the bottom plate of the separation box 3, and the two side ends of the partition plate 4 are welded to the two side walls of the separation box 3 Fixed, the partition plate 4 divides the inner cavity of the separation box 3 into a sludge chamber 5 and a residual water chamber 6, and the height of the partiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com