Wind power generation device capable of being regulated windward and using method thereof

A technology of wind power generation device and gravity, applied in wind power generation, installation/support configuration of wind turbines, wind turbines, etc., can solve the problems of low utilization rate of wind energy, difficulty in exerting efficiency, and high strength requirements, so as to improve utilization rate, reduce Small contact area, ensuring the effect of windward area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

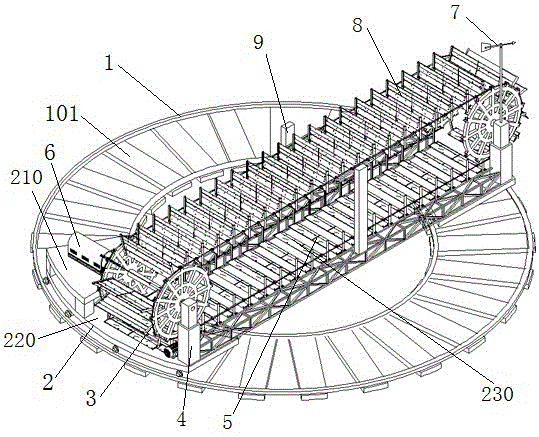

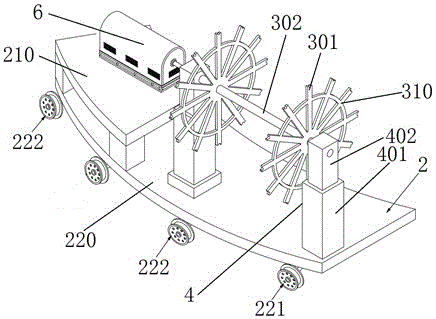

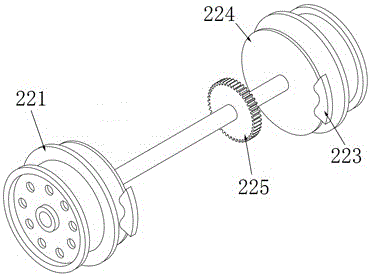

[0031] Such as Figure 1-9 As shown, a wind power generation device that is adjusted against the wind includes an annular base 1, and the annular base 1 is provided with a rigid rotating body 2 that can rotate relative to the annular base 1 according to the wind direction and is radially arranged on the annular base 1. The rigid rotating body 2 is provided with a blade-type rotary transmission mechanism 5, and the blade-type rotary transmission mechanism 5 includes chain transmission mechanisms 3 located on both sides of the rigid rotary body 2, and several chain transmission mechanisms 3 are sequentially arranged between them. The blade mechanism 8 for receiving wind power, the blade mechanism 8 includes a blade body 810 made of flexible material for receiving wind energy, side rails 820 are provided on both sides of the blade body 810, and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com