Positive and reverse rotation overload unloading valve

An unloading valve, forward and reverse technology, applied in the direction of fluid pressure actuation device, fluid pressure actuation system safety, servo motor components, etc., to prevent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

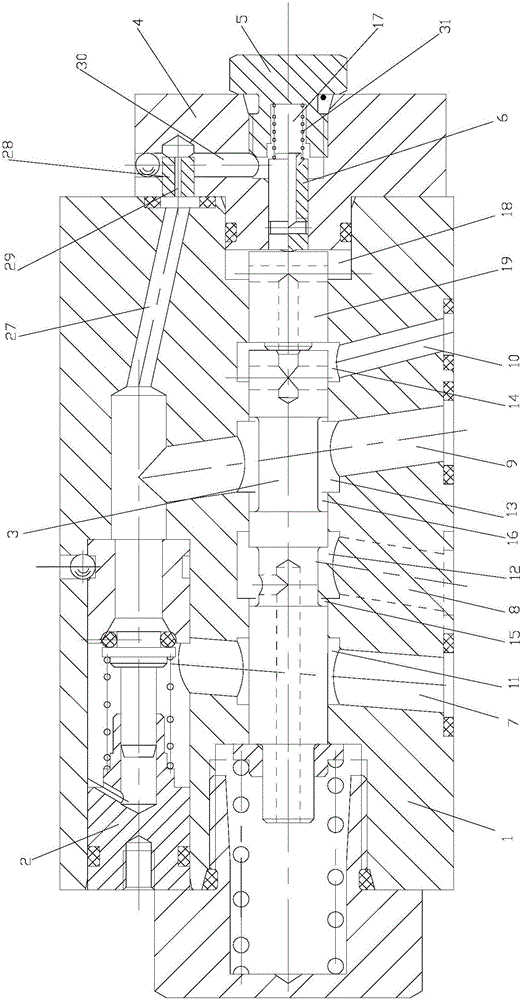

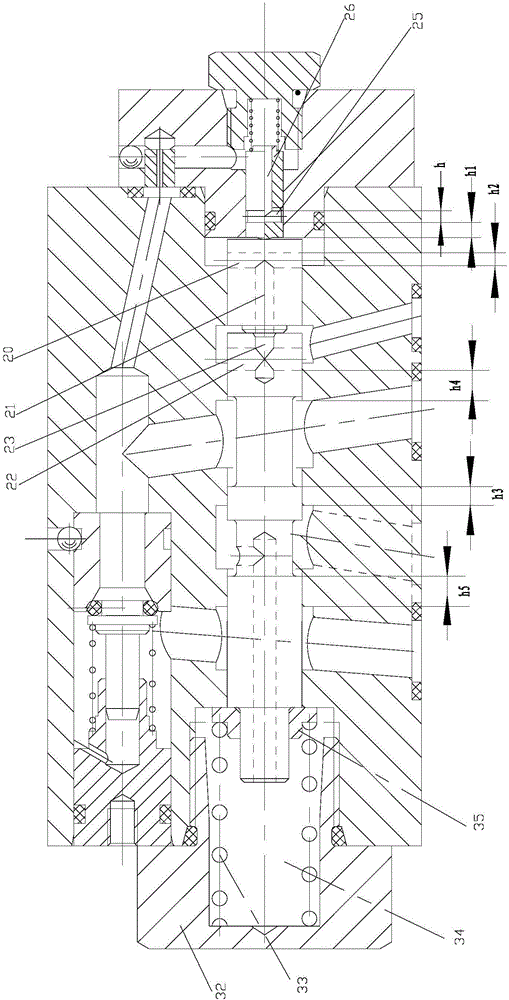

[0017] The present invention will be further described below in conjunction with the drawings and specific embodiments.

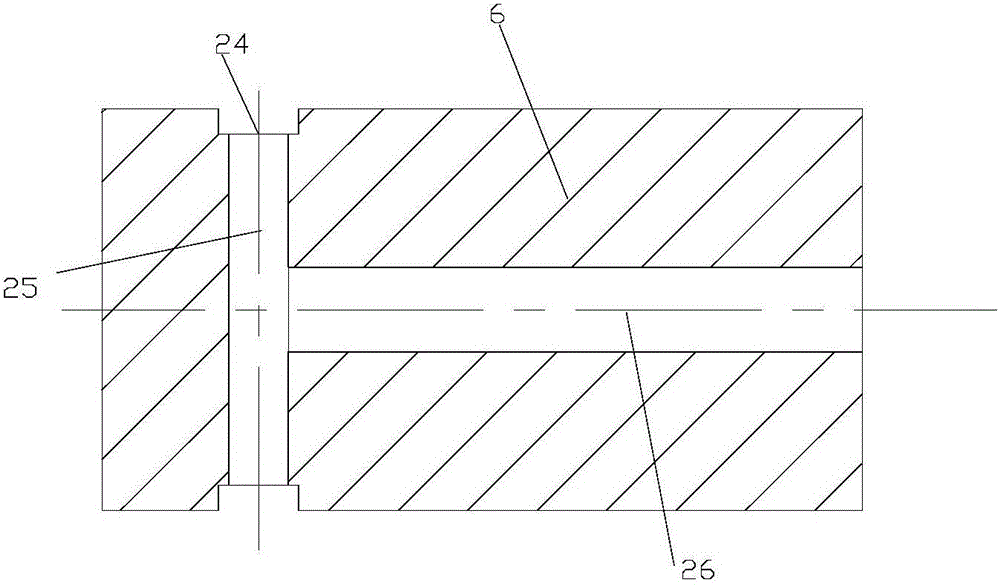

[0018] The working principle of the present invention: when the oil pump is rotating forward, the pressure oil from the oil outlet of the oil pump flows through the oil inlet 9 and the one-way valve 2 on the valve body 1, and then is output from the oil outlet 7 to the oil inlet cavity of the oil cylinder, thereby Make the oil cylinder do work; at the same time, as the pressure of the oil inlet 9 gradually increases, the pressure oil will also flow through the third channel 27, the orifice 29, and the fourth channel 30 to feed back to the first sealed oil chamber on the right end of the control spool 6. 17. Make the control spool 6 overcome the spring force of the spring pressure-regulating assembly, and gradually push the secondary pressure-bearing spool 19 and the main spool 3 to move to the left; until the control spool 6 is provided with a pressure regulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com