Dual-voltage coil for photovoltaic transformer and winding method thereof

A winding method and transformer technology, applied in the direction of transformer/inductor coil/winding/connection, inductor/transformer/magnet manufacturing, coil manufacturing, etc., can solve complex production and manufacturing processes, long winding time of photovoltaic power transformer coils, etc. problems, to achieve the effects of convenient assembly, improved operating performance, and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

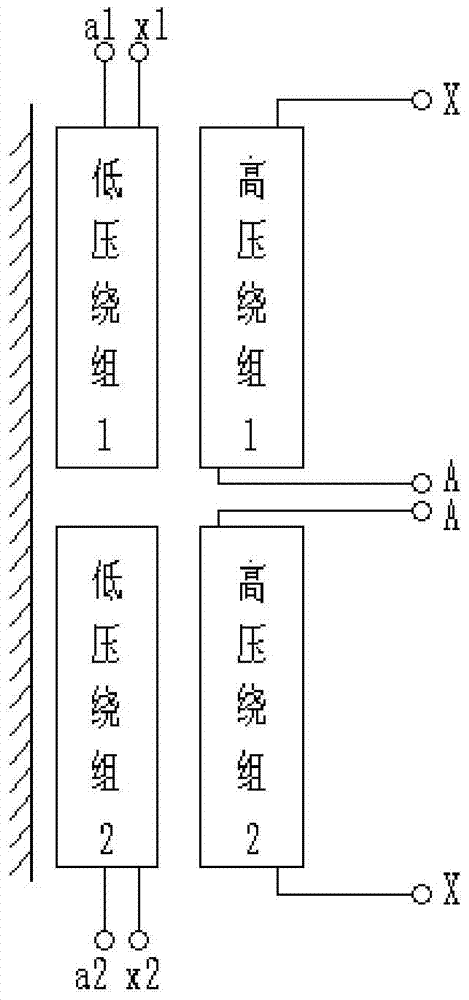

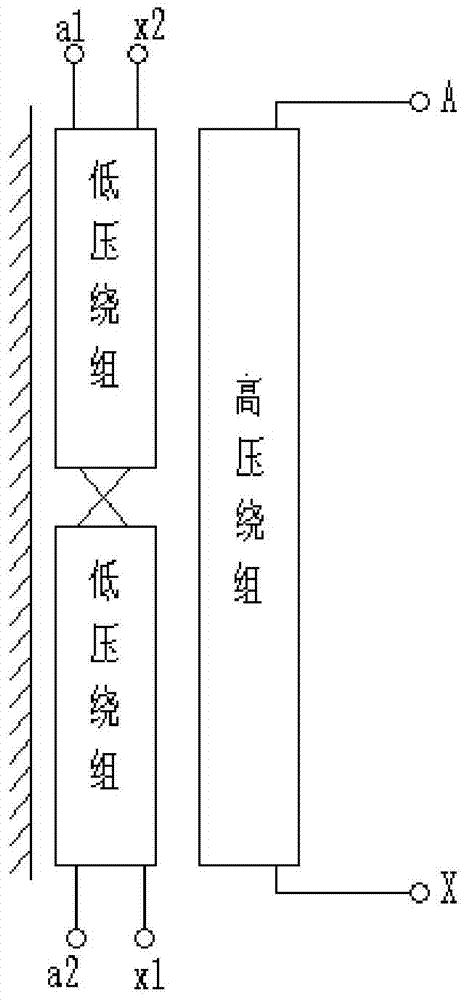

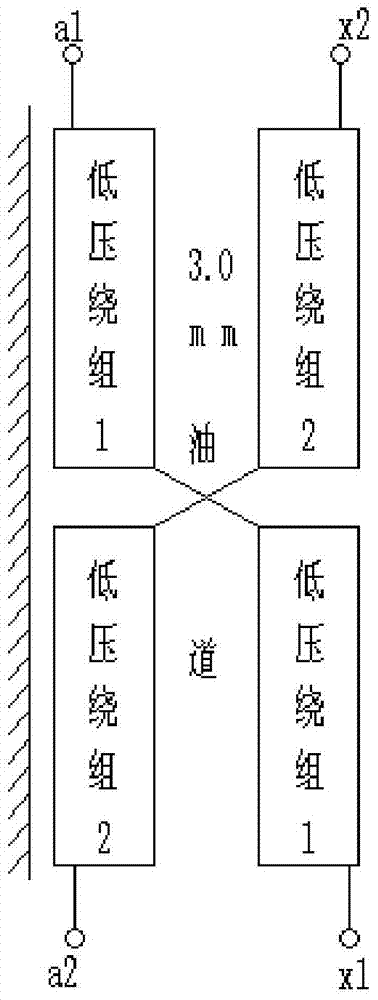

[0034] The dual-voltage coil for the photovoltaic transformer of the present invention, on the iron core of each phase coil, from the inside to the outside, is successively a low-voltage coil and a high-voltage coil, wherein the low-voltage coil is two independent low-voltage windings arranged radially; the high-voltage coil is an independent the coil. Such as figure 2 , 3 As shown, two independent low-voltage windings are cross-transposed through copper foil in the middle of the coil.

[0035] Such as Figure 4 As shown, the winding method of the dual-voltage coil for the photovoltaic transformer of the present invention comprises the following steps:

[0036] Install the coil mold and spread the insulating paper;

[0037] Weld the upper part of the first low-voltage winding with copper foil 1 to the first row of copper bars of the first low-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com