Interactive socket without exposed jacks

An interactive, socket technology, used in coupling devices, electrical components, connections, etc., can solve the problems of excessive interference of the protection door, temperature rise, loss of elasticity of metal sheets, etc., to eliminate the phenomenon of virtual connection and floating, and improve the safety performance. , to prevent the effect of spark flashover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The detailed structure of the present invention is described below in conjunction with embodiment and accompanying drawing, but the present invention is not limited to following embodiment, and various combination implementations in the design framework of the present invention are all within the scope of effective protection.

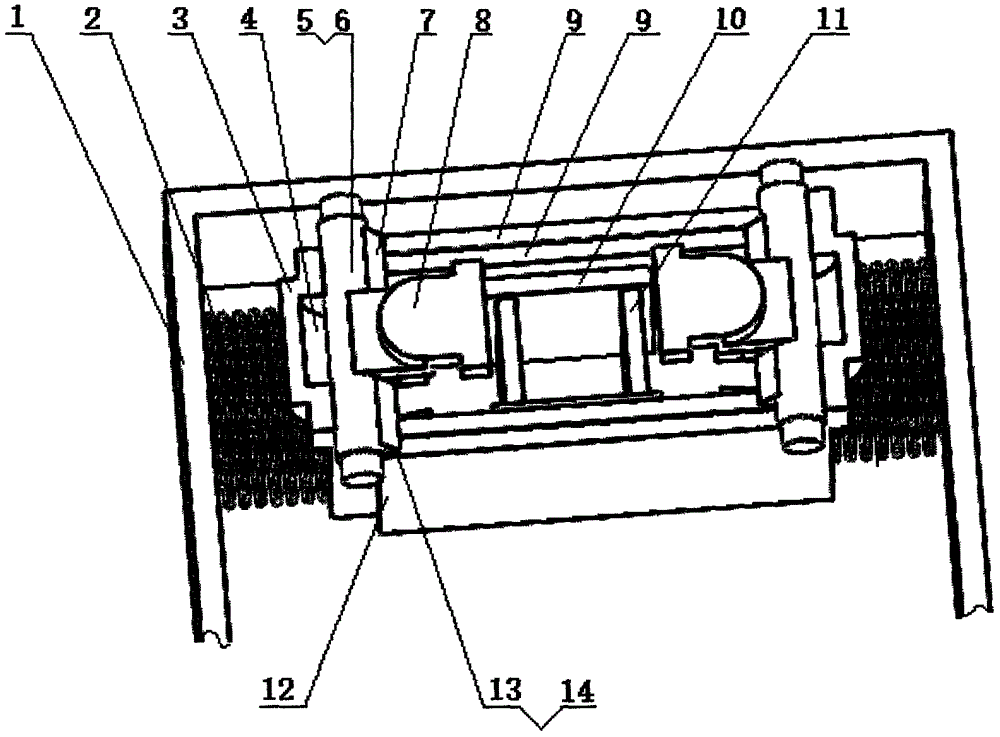

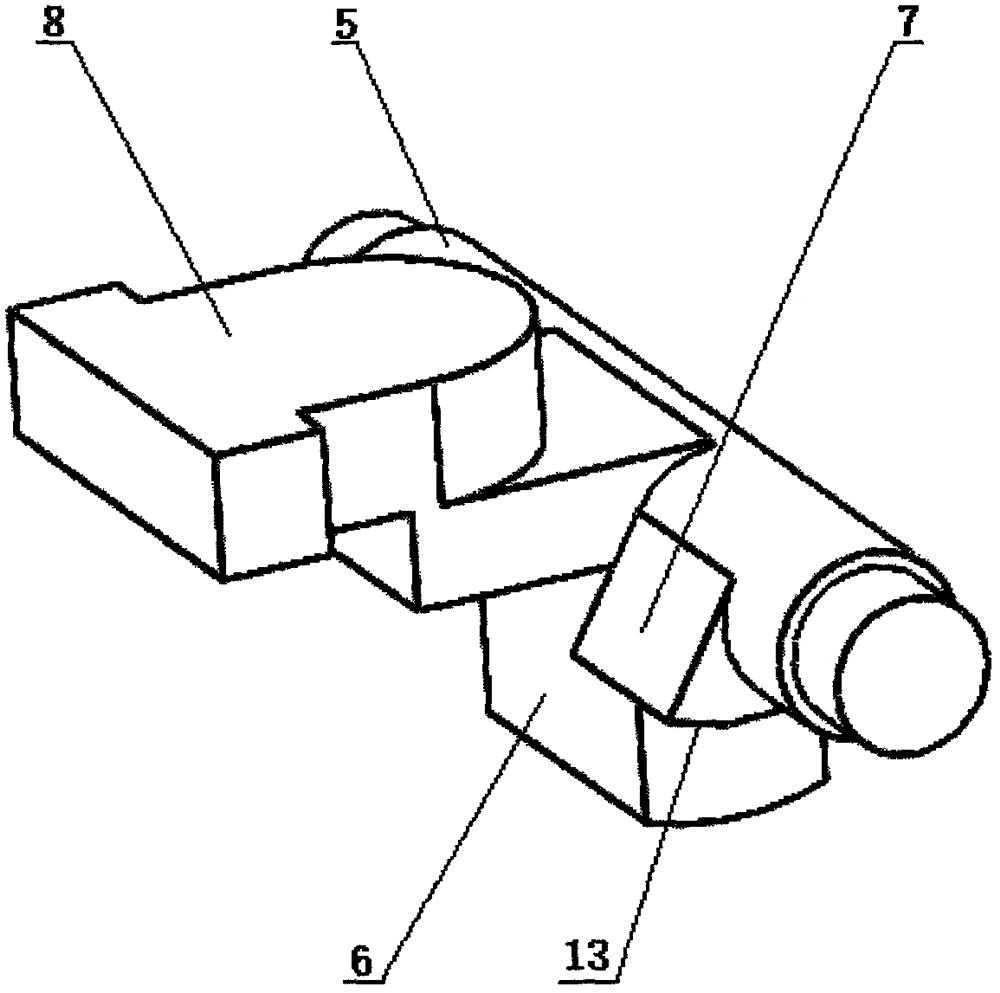

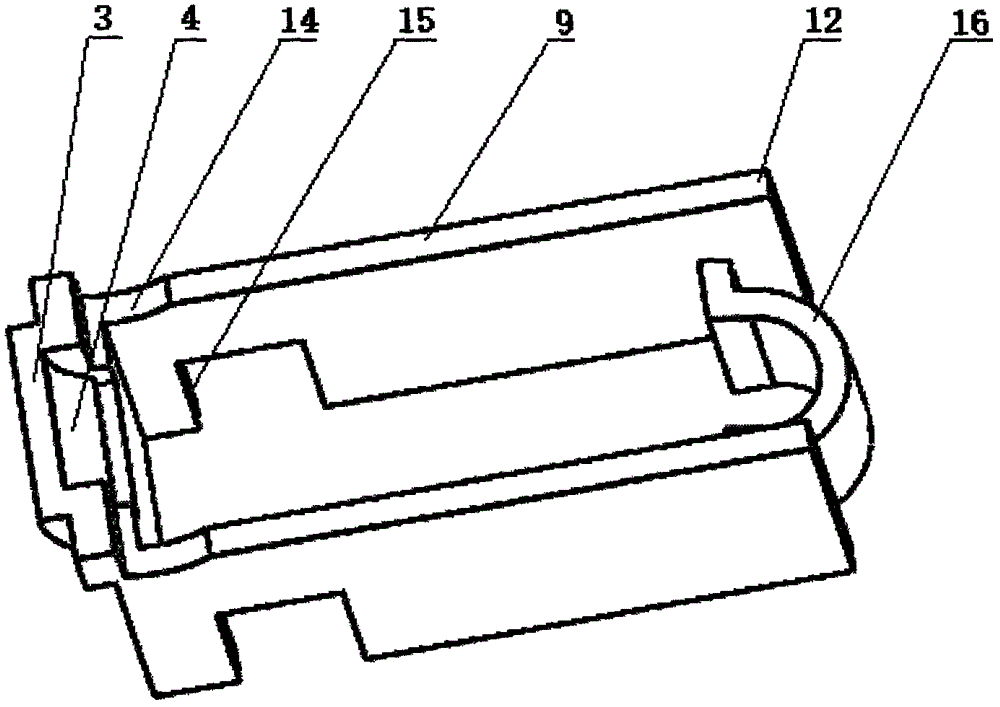

[0031] figure 1 Described is an interactive non-porous socket. The present invention includes: a housing 1, a movable conductive sheet installation device, a protective door device, and an anti-single pressure device. The housing 1 is composed of a socket cover and a socket base. The installation device for the movable conductive sheet includes: a pull box 9, a movable rotating frame 26, a movable seat 19, and a spring 20; . Protect the door shaft 5. The anti-single-pressure device includes, anti-single-pressure slide block 33, linkage plate 39, buckle 38, linkage plate spring 59, anti-single-pressure slope 22, 53, which is characterized in that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com