Rapid positioning transferring method for electronic assembly bearing disc

A technology of electronic components and carrying trays, applied in the direction of electrical components, electrical components, etc., can solve the problems of slow running speed, stop, and limited carrying capacity of the conveyor belt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Before the rapid positioning and transfer method of the electronic component carrying tray of the present invention is described in detail in this embodiment, it should be noted that in the following description, similar components will be represented by the same component symbols.

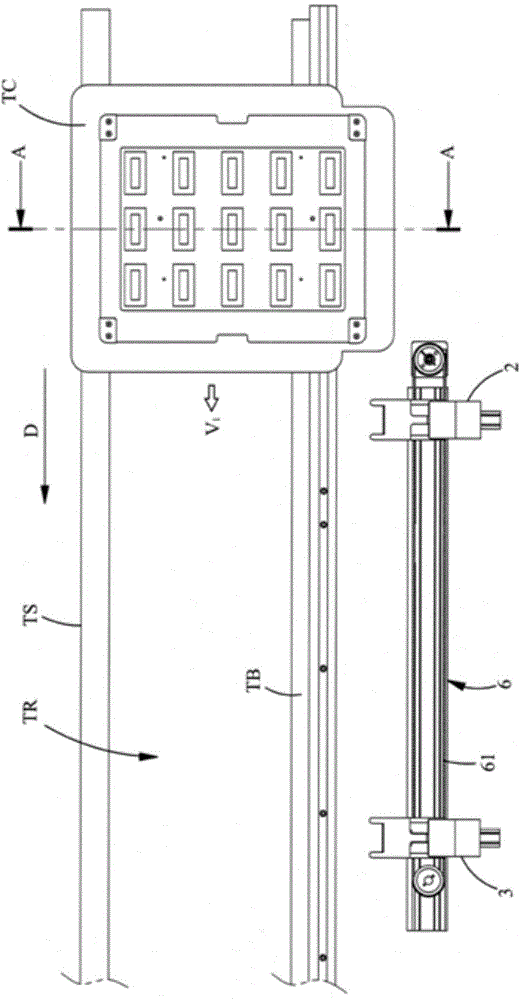

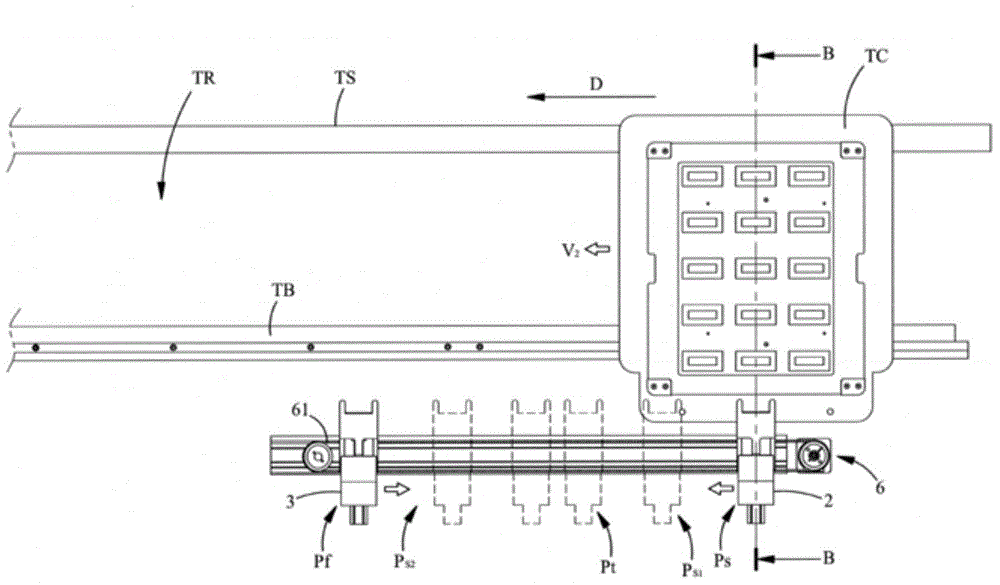

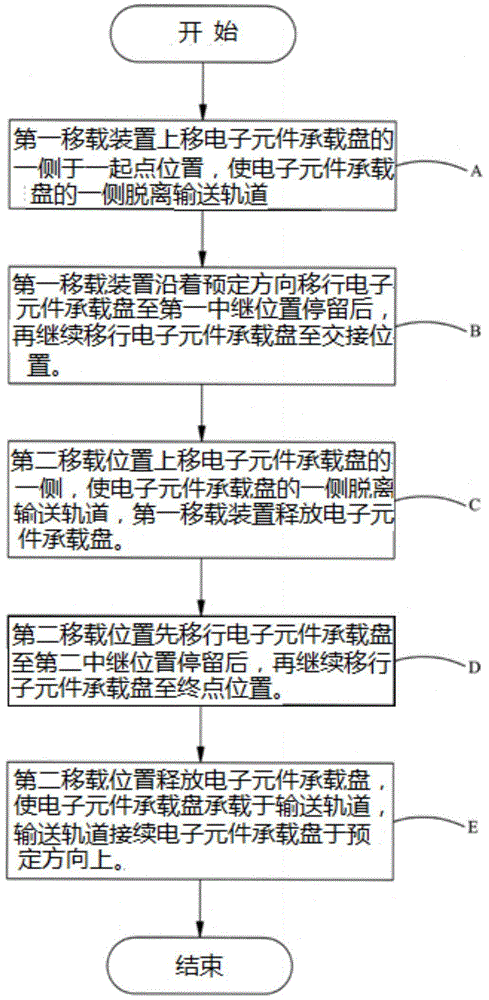

[0041] Please also see figure 1 ,and figure 2 , figure 1 It is a schematic top view of a preferred embodiment of the present invention, figure 2 It is a schematic top view showing the working position of a preferred embodiment of the present invention. As shown in the figure, this embodiment is used to match a transport track TR, but not limited thereto, and the transport track TR transfers an electronic component carrier tray TC in a predetermined direction D. Referring to FIG. In this embodiment, the conveying track TR mainly includes a conveying belt TB and a supporting member TS, wherein the rotation of the conveying belt TB drives the displacement of the electronic component carry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com